With the rapid development of the textile industry, improving production efficiency and reducing costs have become the wastewater treatment tasks of factory managers. The emergence of the Electric Warp Beam Lifting Trolley provides an efficient, safe, and economical solution for textile mills. In this article, we will take a deep look at how the electric warp beam lifting trolley can help textile mills save costs and time.

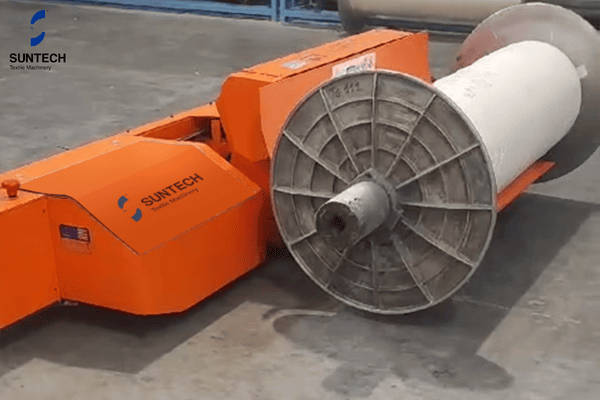

Electric Warp Beam Lifting Trolley

What is the Electric Warp Beam Lifting Trolley?

The electric warp beam lifting trolley is a customized equipment mainly used for warp beam handling and beam loading operations in textile production. Through electric drive and automatic control, the electric warp beam lifting trolley can achieve safe and efficient operation, helping textile mills reduce labor costs and improve work efficiency.

Working Principle of Electric Warp Beam Lifting Trolley

The electric warp beam lifting trolley realizes the rapid handling and precise positioning of the warp beam through the built-in battery and intelligent drive system. The operator only needs to simply control the equipment to complete the task of multi-person collaboration required for traditional beam loading.

Limitations of Traditional Warp Beam Loading Methods

The traditional warp beam loading method usually relies on manpower or manual equipment. This method has the following disadvantages:

Low efficiency: requires collaboration of multiple people, time-consuming and labor-intensive.

Safety hazards: accidents are prone to occur during warp beam handling.

High cost: high-intensity manpower requirements increase the operating costs of enterprises.

Advantage of Electric Warp Beam Lifting Trolley

Improve Work Efficiency

Traditional warp beam handling requires multiple workers to complete, while the electric warp beam lifting trolley can be easily handled by one operator. This greatly shortens the operation time and improves overall production efficiency.

The electric warp beam lifting trolley can not only quickly transport warp beams, but also accurately complete complex operations such as positioning and loading. This automated equipment saves a lot of time for textile mills.

Save Costs

The automated design of the electric warp beam lifting trolley reduces the reliance on manual labor. There is no need to hire a large number of additional workers, which directly reduces the labor costs of enterprises.

Compared with traditional mechanical equipment, the electric warp beam lifting trolley has a compact structure and reasonable design, lower maintenance costs, and longer service life, which further reduces equipment operating expenses.

Improve Production Safety

Warp beam handling is a high-intensity job that can easily cause worker injuries. The introduction of the electric warp beam lifting trolley significantly reduces such risks and ensures the safety of employees.

The electric warp beam lifting trolley adopts a design that meets international safety standards, such as an emergency stop function and a stable electric system, providing higher safety guarantees for factories.

How does the Electric Warp Beam Lifting Trolley Optimize the Textile Production Process?

Reduce Equipment Downtime

Through fast handling and precise shaft loading, the electric warp beam lifting trolley significantly reduces the downtime of the production line and ensures the continuity of the production process.

Improve the Flexibility of the Production Line

The flexible design of the electric warp beam lifting trolley can adapt to the needs of warp beams of different sizes and weights, making the production line more adaptable and meeting various order requirements.

Improve the Coordination of the Production Line

The automated beam loading process reduces human errors, improves the coordination and stability of the production line, and thus improves the overall production efficiency.

Conclusion

As an important equipment in the textile industry, an electric warp beam lifting trolley can not only significantly improve production efficiency, but also help enterprises save costs. By reducing labor demand, optimizing production processes, and improving safety, the electric warp beam lifting trolley is becoming an important tool for textile mills to achieve automation transformation.