Introduction

As the textile industry develops towards intelligence, automated fabric inspection machines have become an important tool for improving production efficiency and product quality. However, when choosing a fabric inspection machine, the degree of automation and budget are two key factors that cannot be ignored. This article will provide you with detailed analysis and suggestions to help you make a wise decision.

What is a Fabric Inspection Machine?

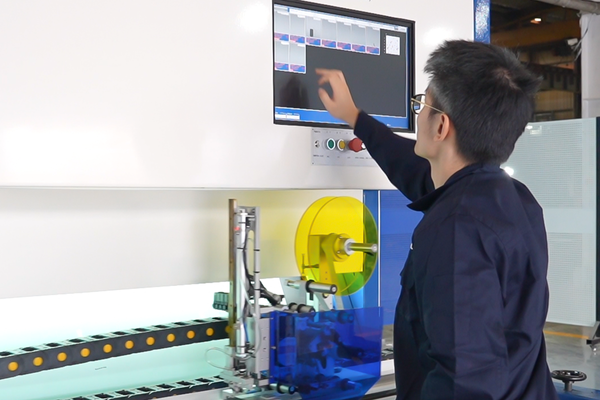

A fabric inspection machine is a device used to detect defects and unqualified parts of fabrics during the production process. Through high-precision image processing and scanning technology, the fabric inspection machine can instantly detect problems such as pinholes, color differences, and fabric irregularities when the fabric passes through. With the advancement of technology, fabric inspection machines have gradually introduced more automated elements, enabling more efficient and accurate inspection work.

Role of Fabric Inspection Machines

In textile production, fabric inspection machines not only improve production efficiency but also greatly reduce the errors of manual inspection and improve the overall quality of fabrics. Whether it is large-scale fabric production or high-demand customized fabrics, fabric inspection machines play a vital role.

The Impact of Automation on the Selection of Cloth Inspection Machines

The degree of automation of a cloth inspection machine directly affects its work efficiency, detection accuracy, and complexity of operation. According to the needs and budget of the enterprise, choosing fabric inspection machines with different automation levels can bring different benefits.

Highly Automated Fabric Inspection Machines

Highly automated fabric inspection machines usually include fully automatic detection systems and artificial intelligence technology. These devices can achieve 24-hour unattended operation and detect every detail of the fabric through AI algorithms. The automatically generated defect maps and detailed data analysis not only improve detection efficiency but also help managers better analyze problems in production.

Application of AI and Deep Learning in Fabric Inspection Machines

With the maturity of AI technology, the automation level of fabric inspection machines is also increasing. AI deep learning algorithms enable equipment to autonomously identify various types of fabric defects and even continuously optimize detection models through learning. This highly automated fabric inspection machine is suitable for enterprises with high-quality requirements and large output.

Moderately Automated Fabric Inspection Machines

For some enterprises with limited budgets but still want to improve production efficiency, moderately automated fabric inspection machines may be a good choice. This type of equipment usually combines manual operation and automation functions, such as semi-automatic inspection of fabrics, where operators only need to intervene at critical moments.

Low-Automation Fabric Inspection Machines

Low-automation fabric inspection machines are mostly manual fabric inspection machines or simple semi-automatic equipment. Although this type of equipment is low in cost, it also requires more manual operation. It is suitable for companies with small production volumes and limited budgets.

Role of Budget in Choosing a Fabric Inspection Machine

When choosing a fabric inspection machine, budget is often the most direct influencing factor. The higher the budget, the higher the degree of automation is usually selected, but this does not mean that highly automated equipment is necessarily suitable for every enterprise. The balance between budget and demand is the most critical.

High Budget and High Automation

If the company's budget is sufficient, choosing a highly automated fabric inspection machine will undoubtedly bring higher production efficiency and more precise quality control. This type of equipment can not only reduce labor costs, but also improve the accuracy of detection and reduce human errors.

Low Budget and Low Automation

For companies with limited budgets, choosing a low-automation fabric inspection machine may be more practical. Although the degree of automation is low, its initial investment is small and the maintenance cost is relatively low. It is suitable for companies with small production volumes or relatively low requirements for fabric quality.

Other Factors

In addition to the degree of automation and budget, there are some other important factors to consider.

Detection Accuracy and Speed

The accuracy and speed of the fabric inspection machine are key factors affecting production efficiency and product quality. High-precision equipment can effectively detect subtle defects, while high speed can ensure high efficiency in large-scale production.

Equipment Maintenance and Technical Support

Automated equipment usually requires regular maintenance and technical support. Choosing a brand with good after-sales service can ensure that the equipment can be repaired in time when it fails, reducing production downtime.

Brand and After-Sales Service

Brand and after-sales service are also important considerations when choosing a fabric inspection machine. Well-known brands usually represent higher equipment quality and stability and can provide long-term technical support and maintenance services.SUNTECH is a professional textile automation machinery manufacturer. Their AI visual fabric inspection machine has been tested by many textile factories and has achieved amazing speed and accuracy.

Conclusion

Choosing a suitable fabric inspection machine requires comprehensive consideration of the degree of automation, budget and many other factors. Under different budgets, companies can choose equipment that suits their production needs, thereby improving production efficiency, reducing costs and improving product quality.