Introduction

The textile industry is one of the oldest and most important industries in the world. With the continuous advancement of science and technology, the textile industry has also ushered in a new era of automation development. Automation can not only improve production efficiency, but also reduce labor costs, improve product quality, and enhance the competitiveness of enterprises. Faced with the global market and consumers' high requirements for quality, the textile industry must quickly adapt to and integrate the development trends of intelligence, digitalization, and greening to meet new challenges and opportunities.

Intelligence

Intelligent Weaving Technology

Intelligence is one of the key trends in textile automation. The application of intelligent weaving technology makes the traditional weaving process more efficient and accurate. For example, modern looms use artificial intelligence algorithms and Internet of Things technology to automatically adjust weaving parameters according to the different properties of raw materials, thereby achieving high-precision and high-efficiency production.

Application of Robots in Textile Production

With the maturity of industrial robot technology, more and more textile production links have begun to introduce robots. For example, automatic cutting machines, automatic sewing robots, and fabric packaging robots are widely used in large-scale production. These robots can not only improve production efficiency but also reduce human errors and ensure the consistency of product quality.

Automated Quality Inspection and Control

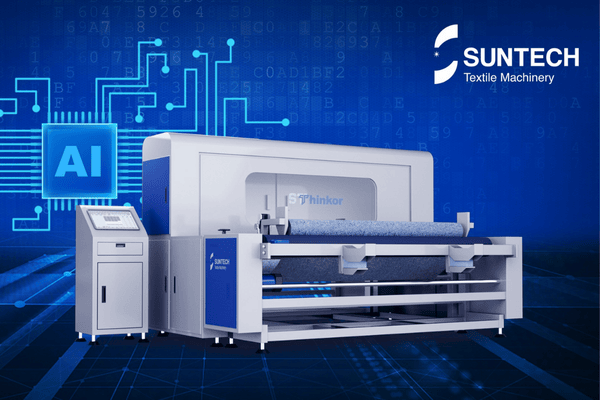

Intelligence is also reflected in quality control. Traditional manual quality inspection often has omissions, while the automated quality inspection system based on artificial intelligence can monitor quality problems in the production process in real time, provide timely feedback and correct deviations. Especially in the production of high-precision fabrics, intelligent quality inspection technology can detect defects that are difficult to detect with the naked eye, ensuring the perfection of the final product.

Digitalization

Application of Big Data in the Textile Industry

Digital transformation makes data management and analysis in the textile industry more important. By collecting and analyzing big data, companies can obtain more market feedback to optimize production processes and product design. For example, by analyzing consumer purchasing behavior data, companies can predict market demand, adjust production plans promptly, and reduce resource waste.

Digital Supply Chain Management

The introduction of digital supply chain management systems has made the supply chain in the textile industry more transparent and efficient. Through the cloud computing platform, textile companies can achieve global supply chain collaboration to ensure the timely supply of raw materials and accurate delivery of products. This system optimization helps to reduce inventory costs, improve logistics efficiency, and achieve rapid response in emergencies.

Virtual Fabric Design and Sample Manufacturing

In the design stage, the application of digital technology makes virtual fabric design possible. Designers can use CAD software to perform virtual design of fabrics, greatly reducing the time cost of paper samples and repeated modifications. The development of 3D printing technology has also made sample manufacturing faster and more accurate, providing great convenience for the early development and optimization of products.

Greening

Textile Technology for Energy Saving and Emission Reduction

With increasingly stringent environmental regulations, the textile industry is accelerating its transformation to green production. Energy saving and emission reduction have become issues that textile mills must pay attention to during the production process. New energy-saving textile equipment, such as low-energy dyeing and finishing equipment and efficient water-saving textile machines, are gradually replacing traditional high-pollution equipment, thereby reducing the negative impact on the environment.

Recyclable Materials

Greening is also reflected in the selection of raw materials. Many textile companies have begun to use recyclable and degradable environmentally friendly materials, such as recycled polyester fibers and bio-based fibers, to reduce resource waste and environmental pollution. These environmentally friendly materials not only conform to the concept of sustainable development, but also meet consumers' demand for green products.

Green Manufacturing and Environmental Certification

Environmental certification has become one of the necessary conditions for the textile industry to enter the market. Many textile companies have passed international certifications such as ISO14001 and Oeko-Tex Standard 100 to prove that their products meet environmental standards. Green manufacturing is not only to meet regulatory requirements, but also an important way for companies to enhance their brand image and win consumer trust.

Technological Progress of Automation Equipment

Intelligent Upgrade of Modern Textile Equipment

The development of textile automation is inseparable from the technological progress of equipment. Modern textile equipment is increasingly integrated with intelligent control systems, which enables the equipment to not only automatically adjust production parameters, but also make real-time adjustments based on data feedback during the production process. For example, automated looms can automatically adjust weaving speed and tension according to different fabrics, thereby achieving high-efficiency and high-quality production.

Automated Looms and Dyeing and Finishing Equipment

Automated looms and dyeing and finishing equipment are the core components of textile automation. These equipment are precisely controlled by intelligent systems, which can greatly improve production efficiency and reduce resource waste. Through automated control, dyeing and finishing equipment can not only accurately control dyeing time and temperature, but also conduct real-time monitoring and data analysis through digital platforms.

Automated Warehousing and Logistics Systems

With the expansion of production scale, textile enterprises are also increasing their demand for warehousing and logistics systems. The application of automated warehousing systems and logistics systems enables textile enterprises to achieve efficient storage of raw materials and rapid delivery of finished products. Automated logistics systems achieve efficient and accurate material handling through equipment such as robots and conveyor belts.

Smart Factories in the Textile Industry: Prospects and Challenges

Construction of Smart Factories

Smart factories are an important direction for the development of the textile industry in the future. Through the integration of automation equipment, artificial intelligence, the Internet of Things and other technologies, smart factories can realize fully automated production lines, greatly improving production efficiency and product quality. However, building smart factories requires high initial investment and technical support, which is still a challenge for many small and medium-sized textile enterprises.

Technical and Financial Challenges Faced

Although the prospects of smart factories are very broad, in practical applications, technical and financial bottlenecks still exist. Many companies need to continuously invest in technology research and development and equipment upgrades, while also solving problems such as talent shortages and technical support.

Steps to Achieve Full Automation

To achieve full automation, textile companies need to start from multiple aspects and gradually promote automation construction. First, it is necessary to upgrade the equipment intelligently, secondly, to improve the digital management system, and finally, to combine green environmental protection technology to achieve sustainable development

Conclusion:

With the acceleration of the trend of intelligence, digitalization and greening, the future of the textile industry will be full of infinite possibilities. Enterprises will further strengthen innovation, promote technological upgrades, and meet the market demand for high-quality, environmentally friendly products. In the future, the level of automation in the textile industry will continue to improve, moving towards a more efficient, more environmentally friendly and more intelligent direction.

Intelligence, digitalization and greening are the three major development trends of textile automation. These trends not only help companies improve production efficiency and reduce costs, but also promote the sustainable development of the industry. With the continuous innovation of technology and the changing needs of the global market, the automation transformation of the textile industry will be faster and usher in a brighter future.