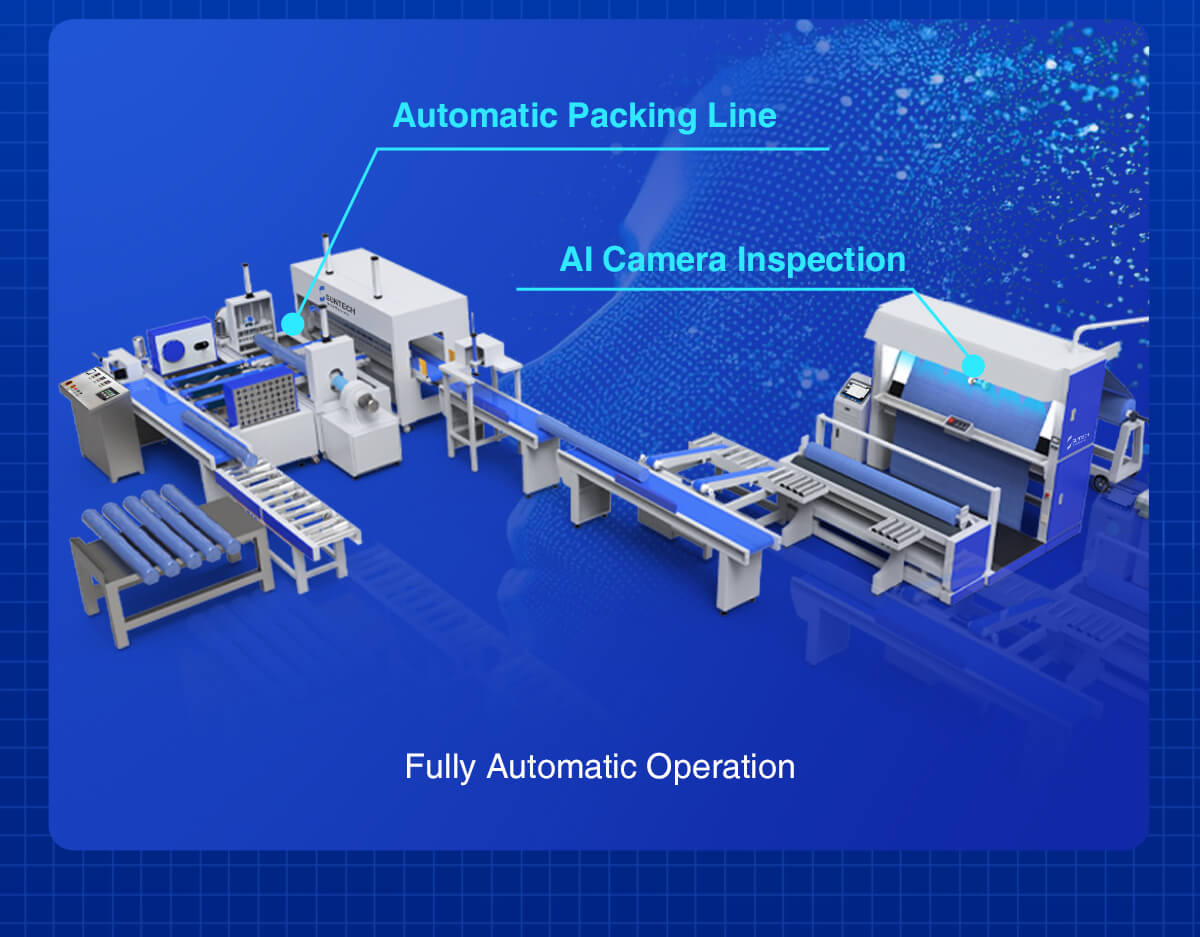

AUTOMATED CAMERA INSPECTION SYSTEM COULD BE INSTALLED ON FABRIC WINDING MACHINES.

NEWLY DEVELOPED AUTOMATIC FABRIC INSPECTION (CAMERA), LABELING, CUTTING, TAPING AND PACKING MACHINE WILL COME SOON.

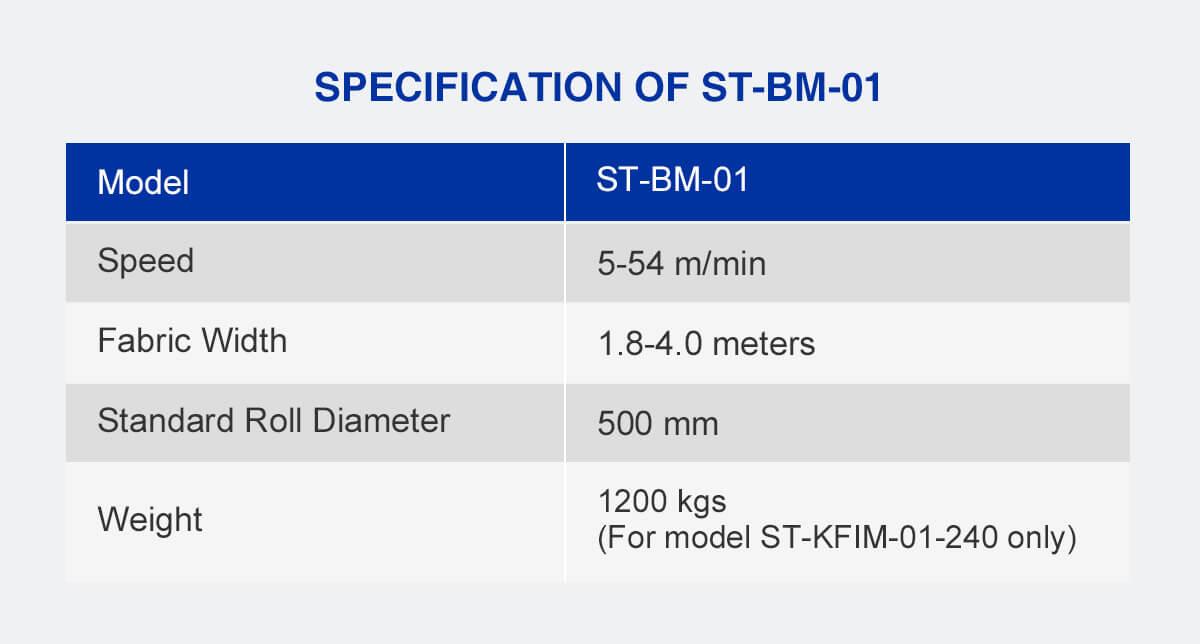

Model

ST-BM-01

Speed

5 - 50 m/min(Standard)

Dimensions(L*W*H)

4370*2350*2210mm

(For ST-BM-01-180 only)

Fabric Width

1.8-4.0 meters

Standard Roll Diameter

500mm

Weight

1300kgs

(For ST-BM-01-180 only)

Electric Specs

3PHASE 380V 50HZ

(can be adjust to suit for diffrerent countries)

Remark:Variable working width is possible and can be tailor-made to your requirements of processing needs.

ST-BM-01 Fabric Winding Machine - Fabric Batching Machine with optional data collection and analysis system (4-point system) to handle a wide range of fabrics, especially for continuous process “A” frame batch and re-winding to small rolls. This machine can provide synchronised fabric input or output to “A” frame with constant tension control, with peripheral fabric contact for delicate or heavy duty fabrics.

1). Direct Centre Driven System for Un-winding

"A" frame fabric is unwound from non-contact centre driven system and wound by surface contact small rolls, especially ideal for checking delicate or heavy duty fabrics.

2). Fabric Input, Output Synchronized- for Tensionless Roll Up

Speed is controlled by an adjustable light accumulation rollers for automatic fabric synchronisation.

3). Full Width Fabric Inspection - with 30 Degree Fixed Angle Inspection Screen

Fabric can be checked under the aid of different viewing and lighting options.

4). Accurate Fabric Length Measuring

Fabric roll length can be taken by industrial standard measuring systems with digital readouts to give consistent fabric roll assessments.

5). Stable Running & Easy Operation

The whole machine is controlled by PLC and the machine can be easily operated with optional Touch Screen.

6). Stretch Fabric Control - with Scroll Roller System and Optional De-curling System

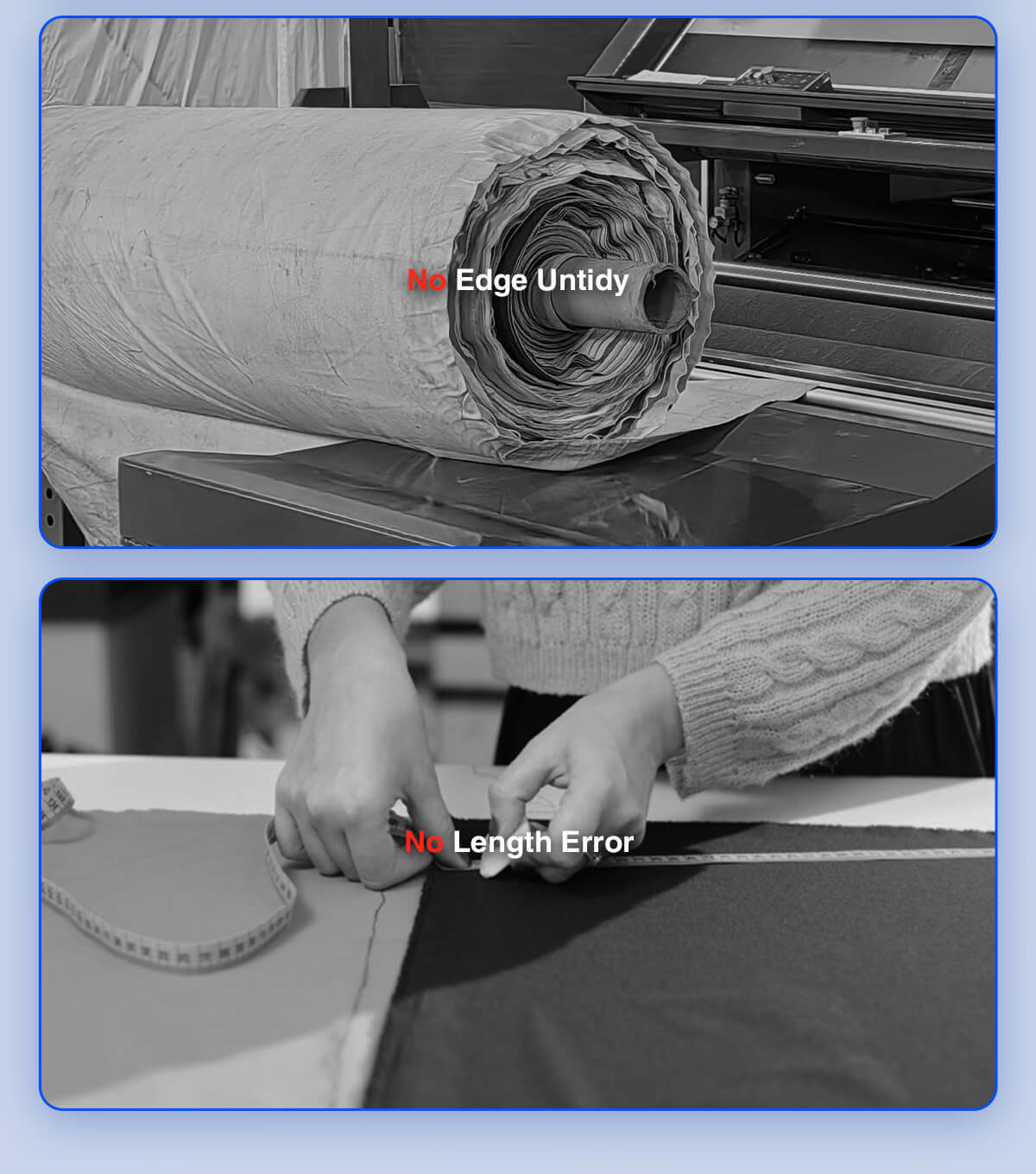

Fabric control at all times to generate consistent roll width and edge output.

7). Versatile Fabric Input and Output Options - Synchronize with Other Production Operations

Optional systems are available for different fabric input and output presentations, continuous fabric input and plait input or output.

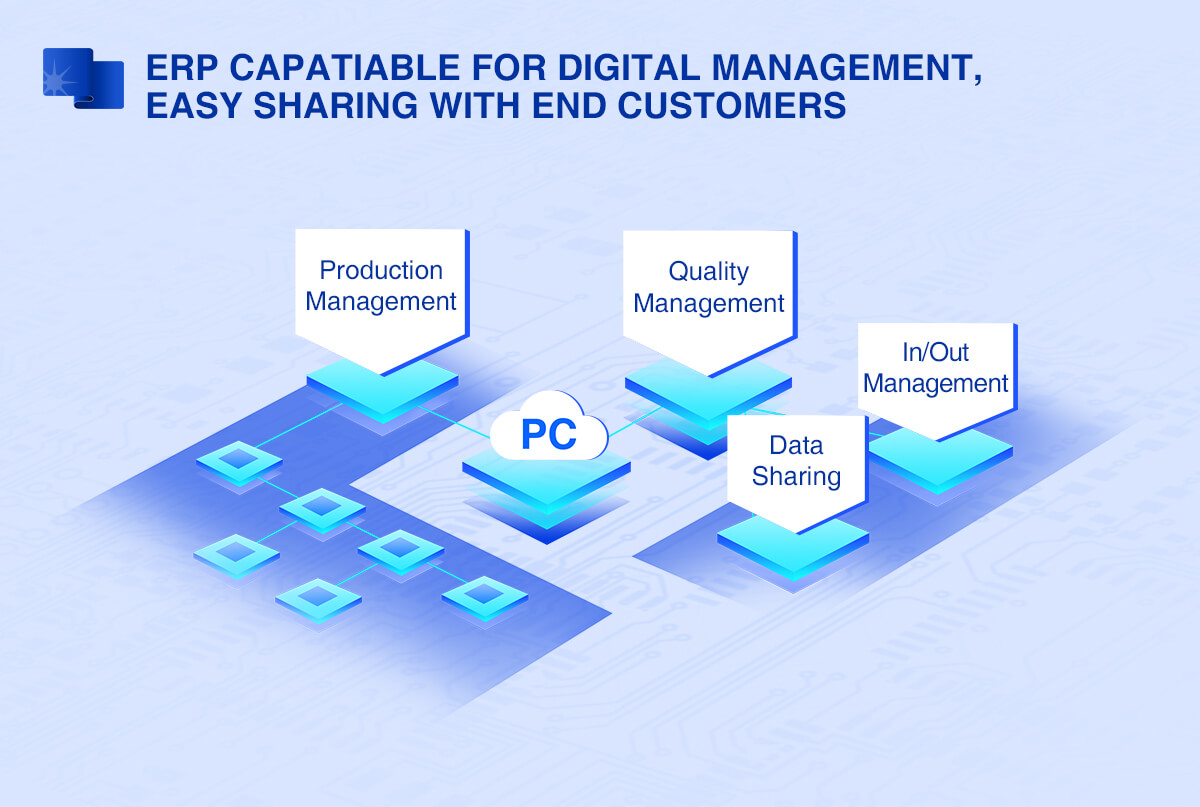

8). Data Collection and Analysis System (4-point System) - Optional

100% fabric inspection with software for accurate fabric roll analysis and printout.

9). Sampling - Optional

Fabric sample can be taken by automatic linear cutter and the rest fabric can be stitched by automatic sewing machine for on going checking.

.jpg)

.jpg)