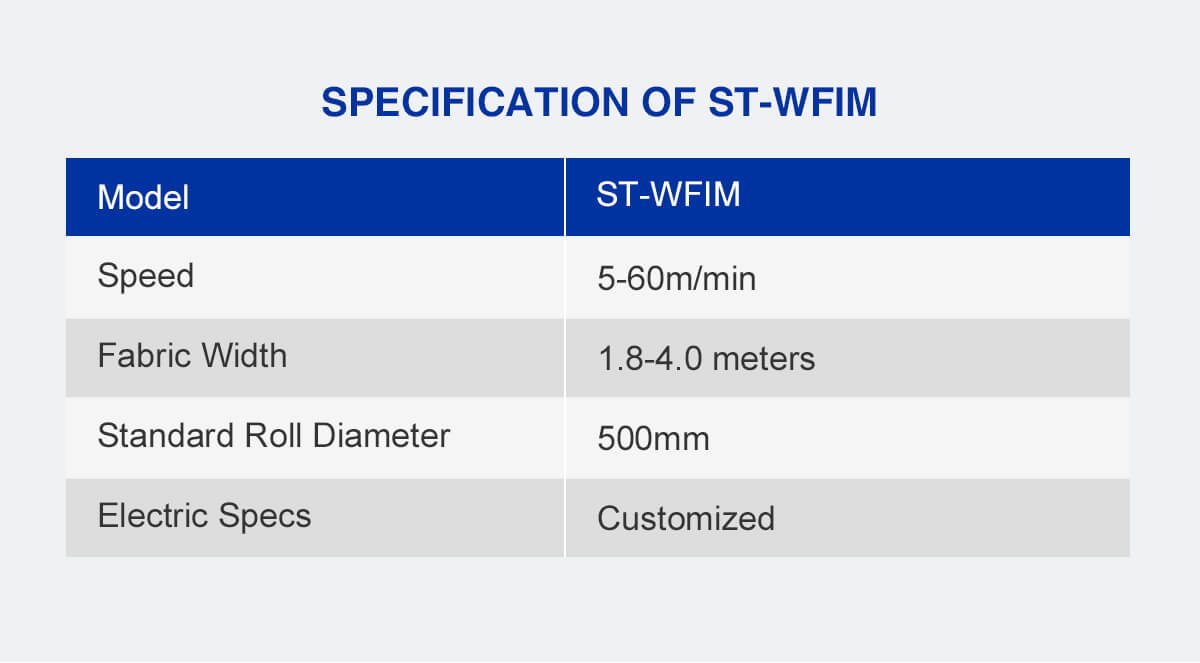

Model

ST-WFIM

Speed

5 - 60m/min

Standard Roll Diameter

500mm

Dimensions(L*W*H)

3050*2630*2430mm

(for model ST-WFIM-180 only)

Remark:Variable working width is possible and can be tailor-made to your requirements of processing needs.

ST-WFIM Fabric Inspection Machine with optional data collection and analysis system (4-point system) to handle a wide range of rolled woven materials.This machine can be supplied to operate from plait/loose fabrics to roll, or with various other fabric inlet and outlet options. Fabric inspection machine price in CN standard but high-quality.

1. End of Fabric Roll Automatic Stop Sensor - for Next Roll Joining

This will Allow for Continuous Fabric Inspection, from One Piece of Roll to Next;

2. Full Width Fabric Inspection

Fabric can be Checked under the Aid of Different Viewing and Lighting Options by its 30 Degree Fixed Angle Inspection Screen;

3. Accurate Fabric Length and Optional Weighing Machine

Fabric Roll Length and Weight can be Taken by Industrial Standard Measuring Systems with Digital Readouts to Give Consistent Fabric Roll Assessments;

4. Accurate Fabric Edge Controlling

Edge Alignment Photo-sensor for Perfect Roll Generation;

5. Consistent Roll Output - With Twin Rewinding Roller and Roll Hardness Adjustment

Processed Rolls are Rewound with the Correct Amount of Tension and are Consistent from Roll to Roll;

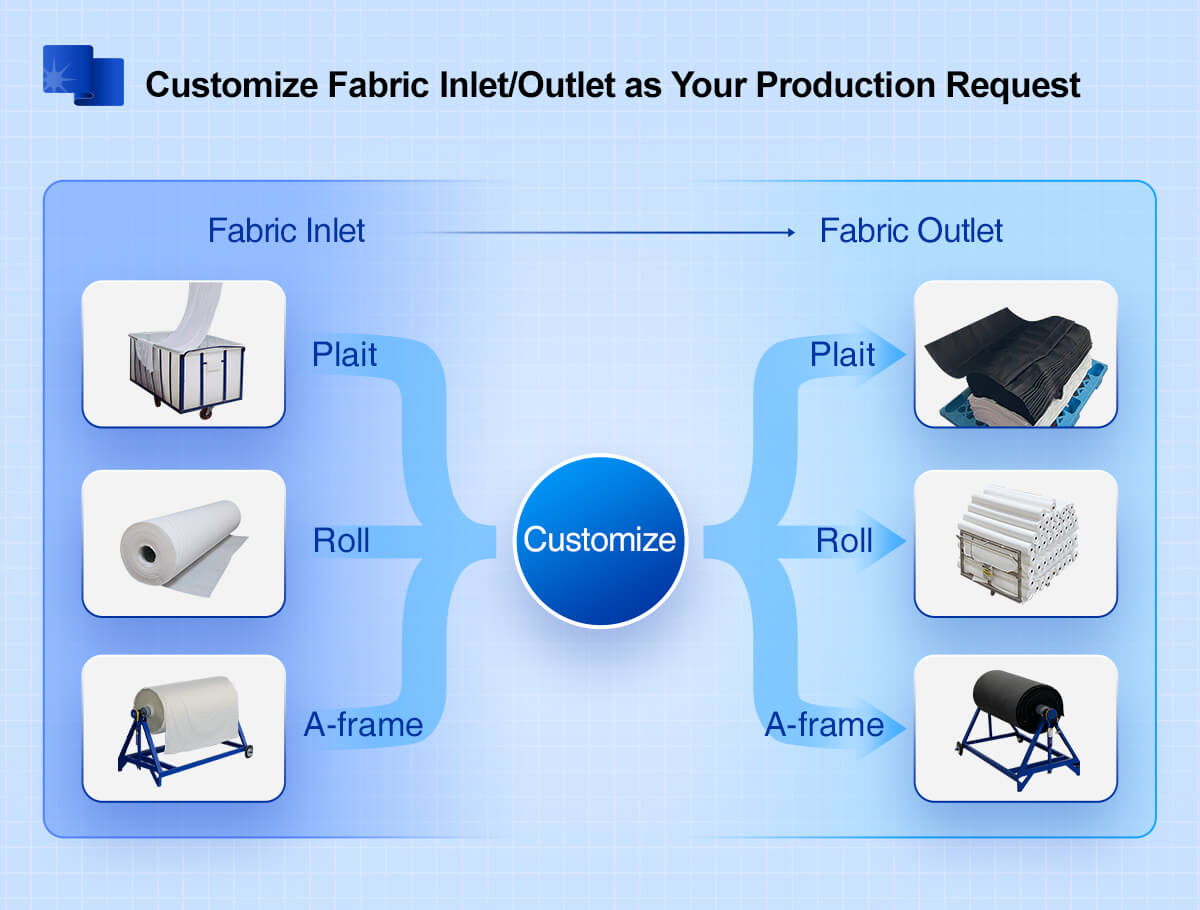

6. Versatile Fabric Input and Output Options - Synchronize with Other Production Operations

Optional systems are available for different fabric input and output presentations, roll to roll, continuous fabric input, etc.

7. Selvedge Shifting Device - Optional

Ideal for for Thick/Sulzer Selvedges;

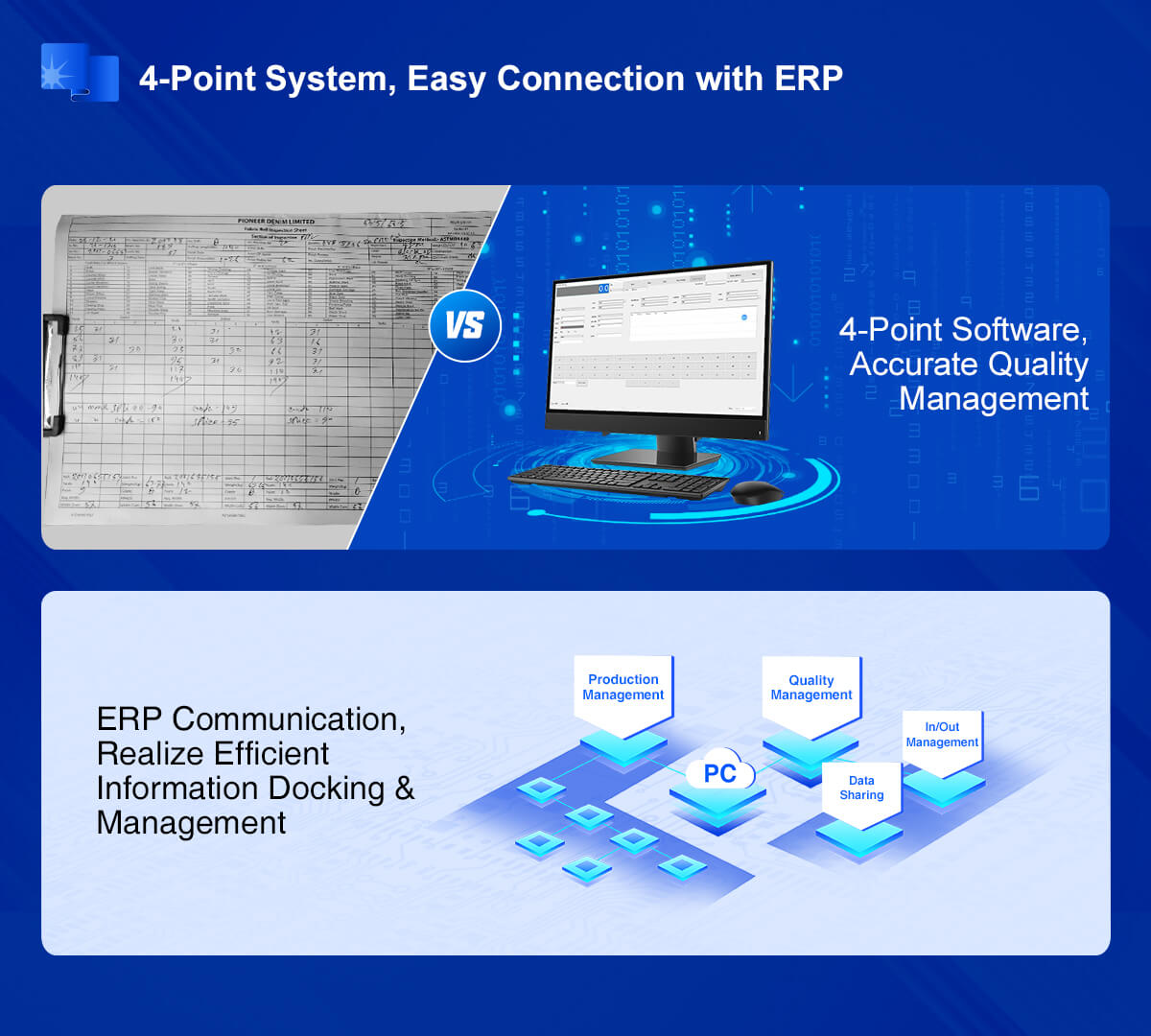

8. Data Collection and Analysis System (4-point System) - Optional

100% Fabric Inspection with Software for Accurate Fabric Roll Analysis and Printout;

9. Linear Fabric Roll End Cutter - Optional

Full Width Cutting at the End of Processed Roll, Fast and Accurate.