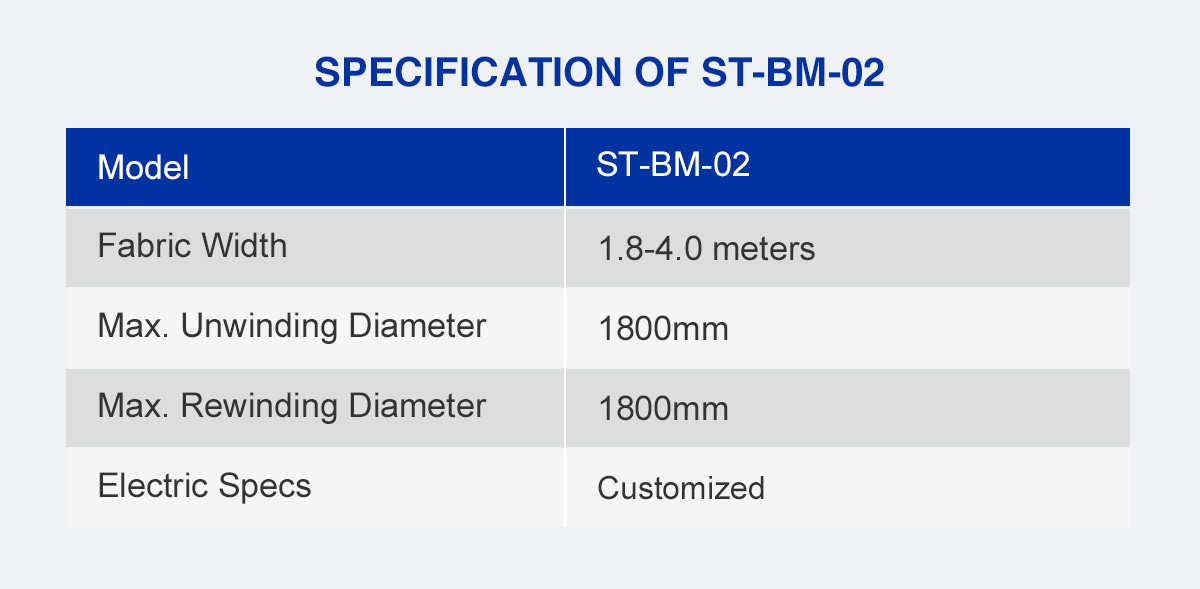

Model

ST-BM-02

Speed

5 - 40 m/min(Standard)

Dimensions(L*W*H)

4800*3100*3000mm

(For ST-BM-01-180 only)

Fabric Width

1.8-4.0 meters

Max.Un-winding Diameter

1800mm

Max.Re-winding Diameter

1800mm

Weight

1300kgs

(For ST-BM-01-180 only)

Electric Specs

3PHASE 380V 50HZ

(can be adjust to suit for diffrerent countries)

Remark:Variable working width is possible and can be tailor-made to your requirements of processing needs.

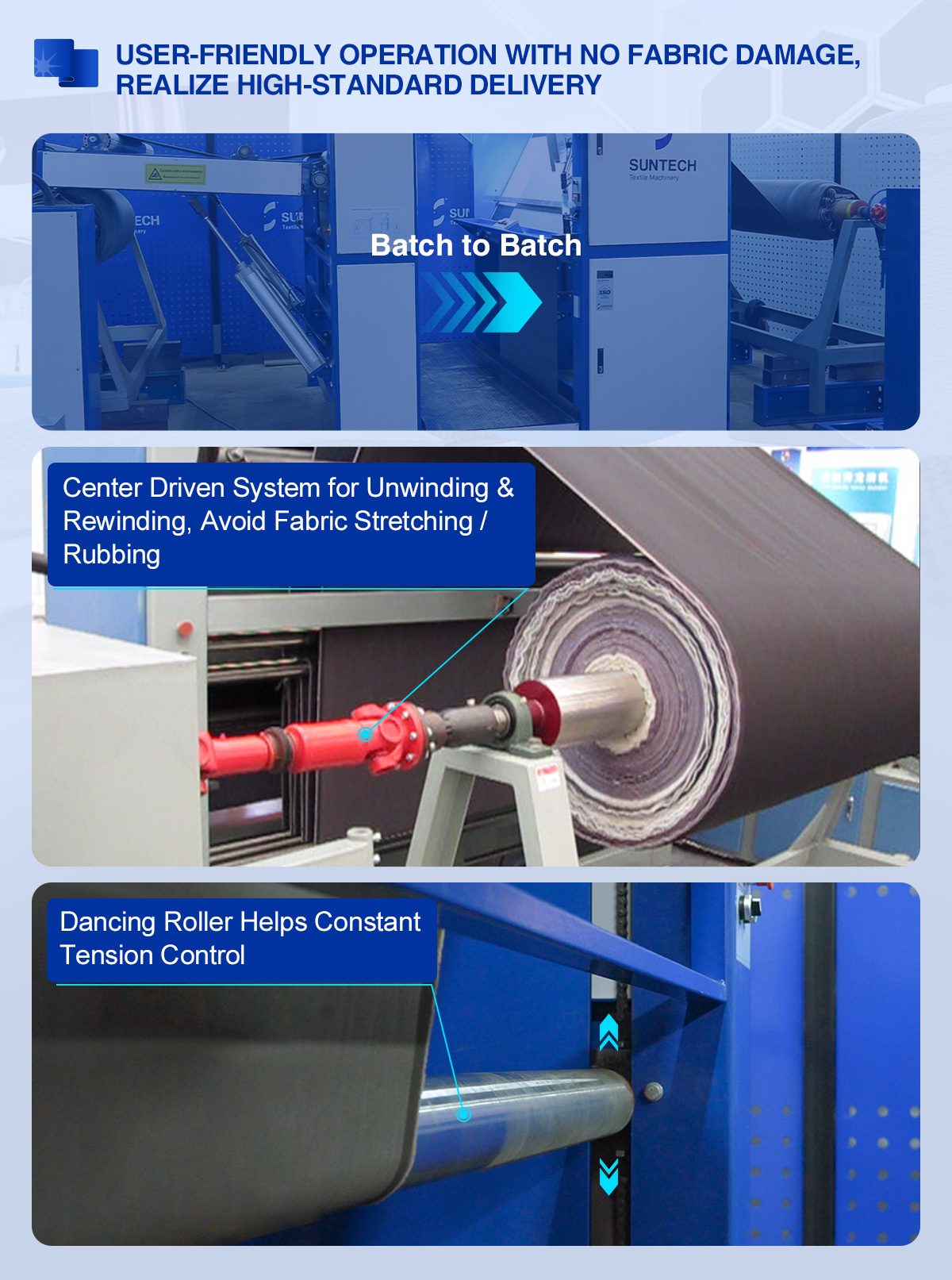

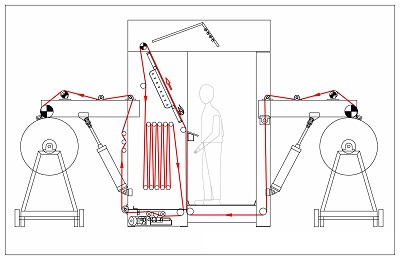

ST-BM-03 Fabric Batching Machine (Batch to Batch)

Continuous process “A” frame batch and de-batch rolling machine, synchronised fabric input or output to “A” frame with constant tension control, with peripheral fabric contact for delicate or heavy duty fabrics.

Optional systems are available for different fabric input and output presentations, continuous fabric input and plait input or output.

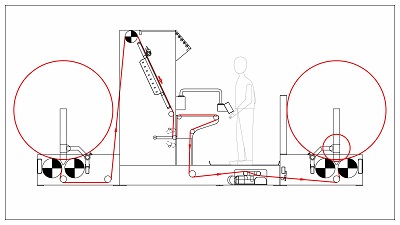

ST-BM-04 Fabric Batching Machine (Big Roll to Small Roll/Big Roll)

Surface winding and re-winding rolling machine for continuous process fabrics from big roll to small roll / big roll, with constant tension control, ideal for heavy duty fabrics.

Optional systems are available for different fabric input and output presentations, continuous fabric input and plait input or output.

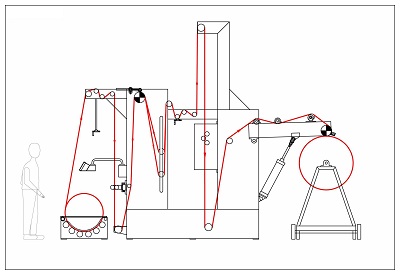

ST-BM-05 Fabric Batching Machine (Plaited Fabric/Small Roll to Bacth)

Continuous process fabrics from plait or small roll to "A" frame with constant tension control, with peripheral fabric contact for delicate or heavy duty fabrics.

Optional systems are available for different fabric input and output presentations, continuous fabric input and plait input or output.

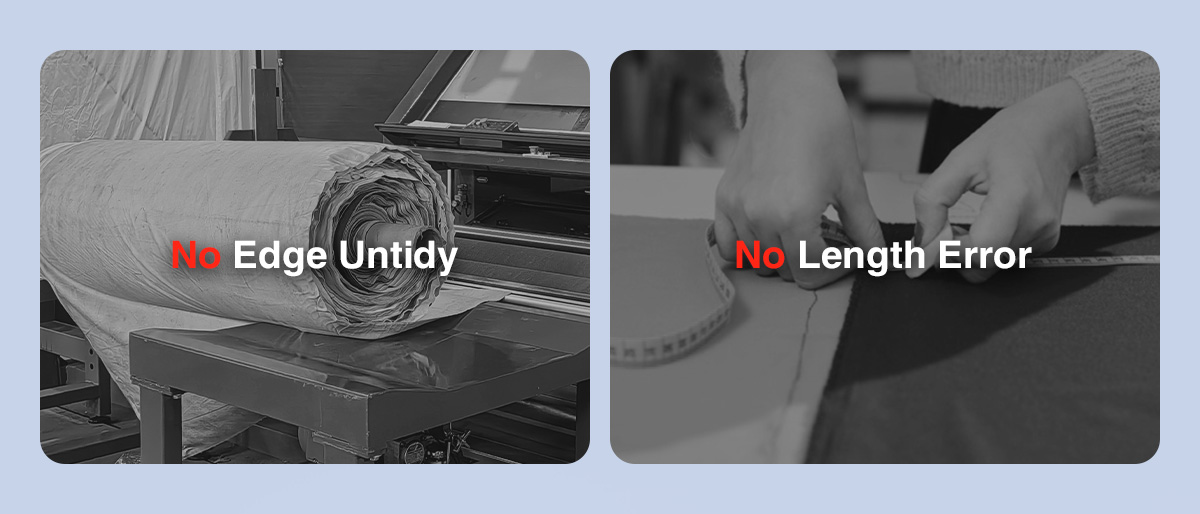

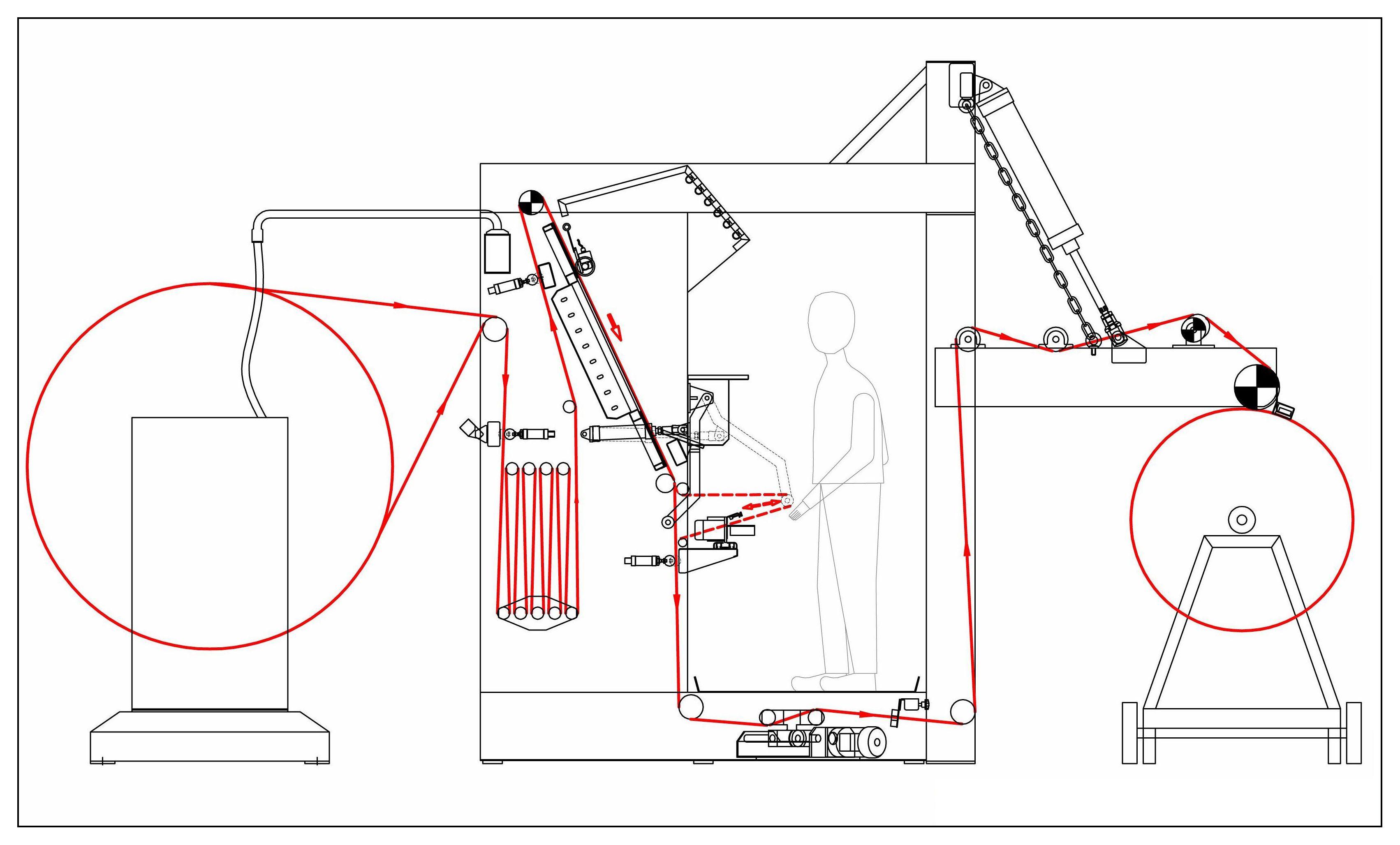

ST-BM-02 Fabric Batching Machine Has a Optional Data Collection and Analysis System (4-point system), is for Handle Various Fabrics, Especially for Continuous Process “A” Frame Batch and De-batch, Providing Synchronised Fabric Input or Output to “A” Frame with Constant Tension Control, with Peripheral Fabric Contact for Delicate or Heavy Duty Fabrics.

Main Functions of ST-BM-02

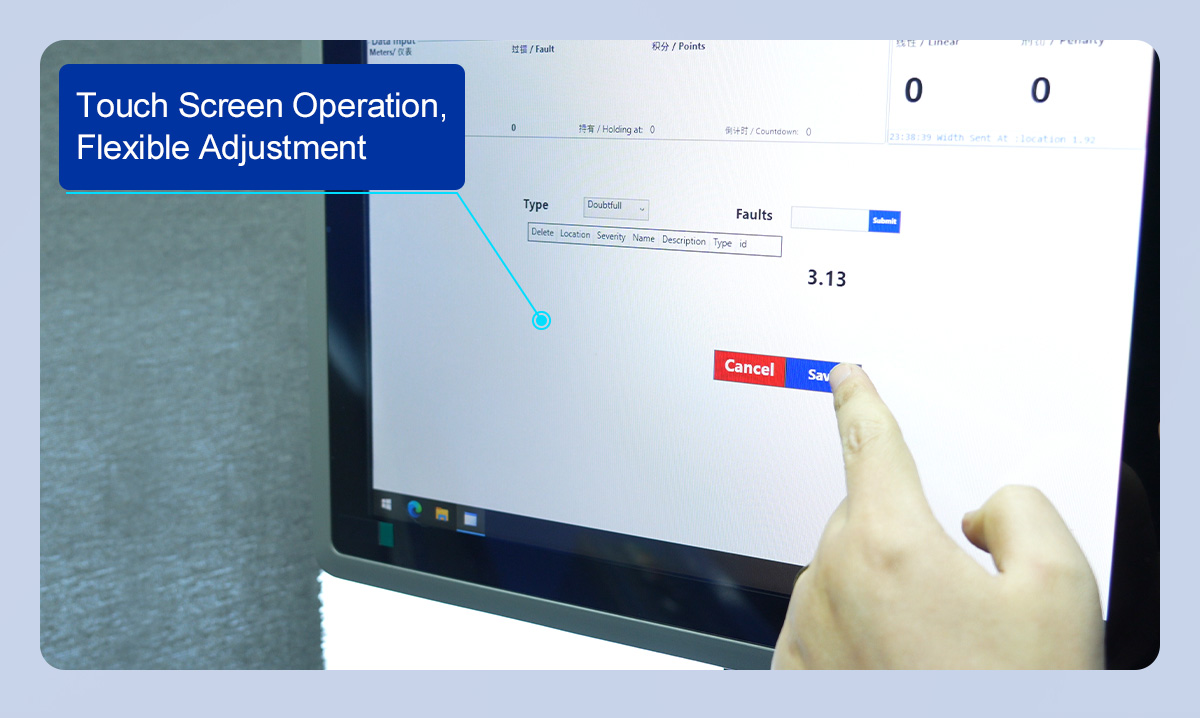

1. Ergonomically Designed;

2. Fast and Easily Handled-Only Requires 1 Operator;

3. Fabric Quality Improving;

4. Synchronize with Production Process;

5. Provide Objective Quality Reporting

6. Reduce Administration