It is known that the textile industry is really important not only in China, but also all over the world. Textile products are widely used by us every day. And with technology development, the textile industry has become more and more intelligent and automatic.

But there are still some problems in the process of storage. Thus, an automatic beam storage system plays a vital role in improving production efficiency. First and foremost, it is easy to be damp and rust if put a warp beam on the ground for a long time, which will shorten the service life. Furthermore, it takes up large warehouse space as well as damages the whole image of the company if they put stack the beams in a mess. In addition, due to unreasonable stacking, the required beam may be difficult to take out, which may waste time and manpower. Last but not least, rolling off the warp beam may cause safety problems, like personal injury, because the warp beam is too big to roll.

SUNTECH is a leading weaving machine manufacturer with more than fifty years of experience and development. Our products include automatic loom, Weaving Machine, rapier loom, etc. What we only focus on is providing global customers optimal products and service through intelligent equipment, helping you become a trustworthy supplier in the market.

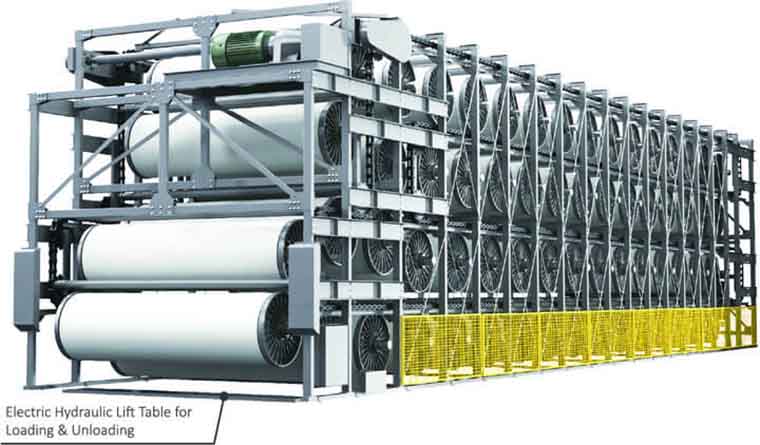

Computerized Warp Beam Storage System ( Beam Stacker )

SUNTECH Beam Stacker can be applied widely and it is the best solution for storage of various beams, such as warp beam, size beam, weaving beam, cloth beam and so on. It is applied in the weaving preparation workshop and weaving unit, as well as finishing unit for space utilization widely, which can also avoid damage from ready warp and cloth beam.

Features

Seven Smart Applications

1. With location beam position, it can select the shortest path to doffing beam automatically.

2. Software with beam search function helps you find designated beam automatically.

3. Connected with ERP system, it realizes data synchronization and sharing.

4. Scan code function makes read and input information automatically.

5. It provides customized language.

6. Software can be customized so it can satisfy your specific requirements.

7. Mobile APP controlling is available.

Seven Quality Guarantees

1. Raw material guarantee, sourcing from international standard steel giants.

2. Precision guarantee, running wheels, chains, rollers are processed by high precision CNC center

3. Machine guarantee, CNC cutting and welding, conform to crack testing report.

4. Artistic appearance, special shot blasting technology can improve the fatigue strength, enhance the coverage and optimize surface roughness.

5. Double rustproof guarantee, epoxy primer and surface metallic painting.

6. With the newest chain synchronization automatic detection technology, zero accidents can be guaranteed. Meet European Safety Standard and all electrical appliances from French “Schneider”.

7. Factory qualification guarantee, SGS approved, meet ISO standards

Seven Security Guarantees

1. CE certificate, Directive 2014/35/EU, conforming to EU electrical safety and mechanical safety standards

2. Automatic chain synchronization detection technology ensure zero accidents.

3. When items enter the inside of the beam stacker, the machine will detect it and stop it immediately.

4. Limit switch to ensure that there is a safe gap between beams and pillars.

5. Safety guardrail keeps potential safety issues away.

6. The loading capacity of beam is 1.5 times more than the bam weight.

7. Double security is provided by extra loading chain.

SUNTECH does everything to enhance the quality of our products and offers you optimal service. Welcome to contact us or visit our website to get more information. We are always ready to give you the best service.