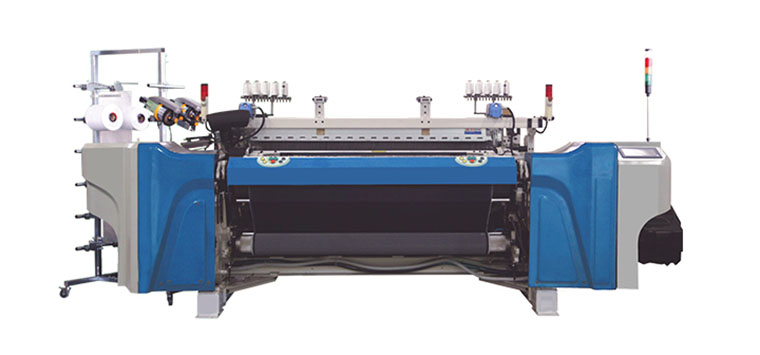

A rapier weaving machine can produce high-quality fabrics at a cheap price, and they are easy to use. This production process for fabric weavers is characterized by a high degree of user friendliness and versatility, making it a great choice for them.

What Is Rapier Weaving Machine?

A Rapier weaving machine does not need the use of a shuttle. Using finger-like carriers, it is possible to move the filling thread to the other side of the loom and then back through the shed of the warp threads again. This kind of machine, which is a competitor to the missille looms, is also available.

There are two primary types of rapier looms: long rapier and single or double rapier. Long rapier looms are the most common kind. If you are weaving with just one rapier, the weft yarn is moved from one loom to the next across the width of the fabric.

As soon as one rapier passes half of the warp yarn to an arm on the opposite side, the other arm reaches in and grabs the remaining warp yarn across the table.

The filler yarn is transferred to the other side of the loom by finger-like carriers called as rapiers, which pass through the shed of warp threads on this shuttleless weaving loom. The principal purpose of these machines is the weaving of textiles such as shirting, dress material, and furniture upholstery.

Which Is the Main Advantage of Rapier Weaving?

Rapier machines have the advantage of being able to lay picks in a range of colors, which is a significant advantage. They are also capable of weaving yarns of any kind of fiber and weaving fabrics up to 110 inches wide without the need for any modifications.

The following are the most significant advantages of using a rapier weaving machine:

1.The rapier weaving machine is much too precise when it comes to weft patterning.

2.Operation of the rapier weaving machine is quite simple and basic.

3.Fine textiles are manufactured in this region.

4.The manufacturing cost of this rapier weaving machine is greater than the average.

5.This rapier weaving machine consumes less power when compared to other kinds of loom machines.

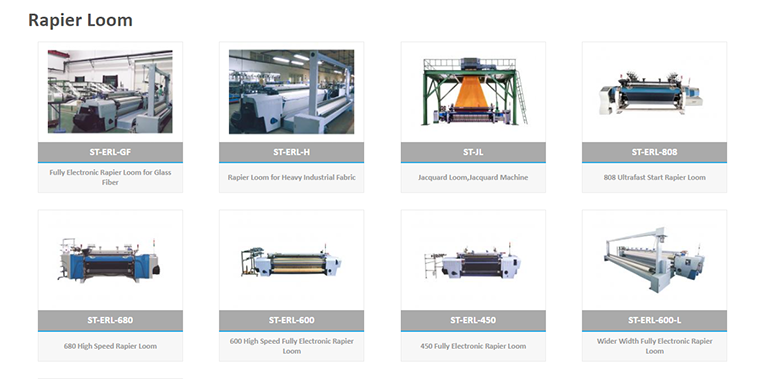

What Do We have For These Rapier Weaving Machine?

For example, you can get:

1.ST-ERL-680 (680 High Speed Rapier Loom)

2.ST-ERL-H (Rapier Loom for Heavy Industrial Fabric)

3. ST-ERL-GF (Fully Electronic Rapier Loom for Glass Fiber)

For more information, don’t hesitate to discover more with a simple click.

Why You Should Choose SUNTECH?

SUNTECH rapier weaving machines are renowned for their ability to compete in a broad variety of applications while remaining innovative, prolific and adaptable.

In the market for a weaving machine? SUNTECH can assist you in identifying the most appropriate alternative for your requirements.

SUNTECH's weaving machines, looms, and other equipment are among the most advanced available on the market.

The ST series weaving machines are built on traditional high-speed rapier looms, automated looms, and jacquard looms, which serve as the foundation of the industry.

It is currently the major emphasis of the company to manufacture specialized textiles such as glass fiber, carbon fiber, industrial, and so on.