What Is Woven Fabric And What’s The Function Of Woven Fabric?

Woven fabrics are made by weaving machine in the form of shuttles, and the yarns are interlaced in the warp and weft directions. Woven fabric is typically used in clothing, garments, for decoration, furniture or covering purposes such as carpets. Different interweaving methods can form different fabric weaves and fabric pattern.

What’s Is The Fabric Weave?

Original fabric weave (also known as basic fabric weave, three original fabric weave) is the basis of other complex fabric weave in the fabric weave. The original fabric weave of woven fabrics includes: plain weave, twill weave and satin weave.

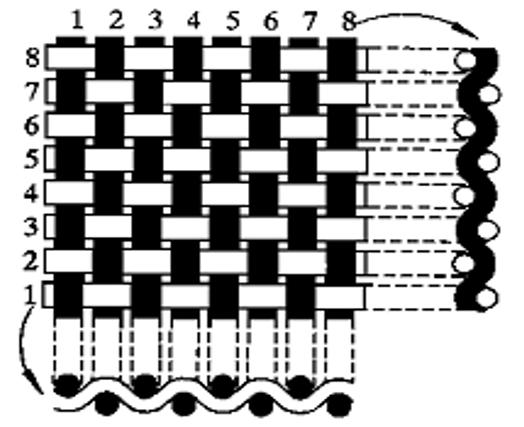

Plain Weave:

.png)

The warp and weft yarns of the fabric are intertwined the most, the plain weave fabric surface is flat, the body is stiff, the texture is firm, and the appearance is tight; the disadvantage is that it feels hard and has poor elasticity.

Common plain weave fabrics are as follows:

Cotton: Muslin, Plain, Coarse, Poplin, Canvas, Etc.

Linen: Summer Cloth, Linen Cloth, Sackcloth, Etc.

Silk: Taffeta, Electricity Texture(Habotai), Georgette

Wood: Palace, Tropical Suiting, Tweed, Etc.

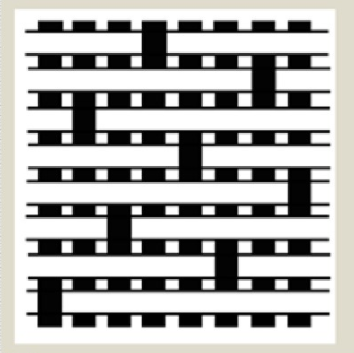

Twill Weave:

.png)

.png)

Due to the few interweaving points of warp and weft, the twill weave fabric’s softness and luster are better than plain weave’s, but its abrasion resistance is poor. In the case of the same density of warp and weft yarns, the strength of twill is not as strong as that of plain weave, so the twill weave in factories generally increases the density of warp and weft yarns and improves its strength.

Common twill weave fabrics are as follows:

Cotton: Twill, Khaki, Denim, Etc.

Wood: Serge, Gabardine, Semifinish, Uniform Cloth, Etc.

Silk: Silk Twill, Rayon Lining Twill, Etc.

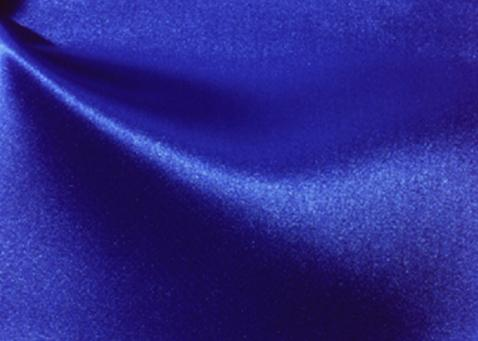

Satin weave:

The satin weave fabric has the fewest interlacing points of warp and weft, only long warp floating yarns or weft floating yarns can be seen, no warp and weft interweaving points, and no oblique or straight lines. Its cloth surface is smooth and even, full of luster, soft texture, but poor abrasion resistance, easy to fluff and snag.

Common twill weave fabrics are as follows:

Cotton: Satin Drill, Sateen

Wood: Venetian

Silk: Tapestry Satin, Floral Satin, Crepe Satin, Brocade, Etc.

How To Produce The Woven Fabric?

The above fabrics are all woven by weaving machine. Common weaving machine include shuttle looms and shuttleless looms: shuttle looms are looms that use traditional shuttles (wood or plastic shuttles) for weft insertion. But the shuttle of loom is large in size and heavy in weight, and is repeatedly projected by exchanges, so that shuttle weaving machine has large vibration, high noise, slow speed and low efficiency. With the development of weaving machine, shuttleless loom is more popular~ There are various ways of weft insertion on shuttleless looms, including rapier, jet (air jet, water jet), projectile, multi-shed (multi-phase) and weaving.

Common weaving machine are rapier weaving machine, water jet weaving machine and air jet weaving machine:

1) Rapier Loom(rapier weaving machine)

Use rigid or flexible rapier heads, belts to hold and guide the weft. In addition to being suitable for weaving plain and textured fabrics, rapier looms are characterized by easy color change, suitable for multi-color weft fabrics, and are suitable for the production of yarn-dyed, double-layer fleece fabrics, terry fabrics and decorative fabrics.

2) Air-jet Loom(water jet weaving machine)

The weft yarn is pulled by the jet of compressed air, and the weft yarn is taken through the shed. Air-jet looms are characterized by high speed and high labor productivity, and are suitable for the production of plain and textured fabrics, fine and extra-high-density fabrics and fabrics in large batches.

3) Water-jet Loom(air jet weaving machine)

Using water as the weft insertion medium, the weft yarn on the fixed bobbin is introduced into the shed by the frictional traction force on the weft yarn by the jet of water. The water jet loom has the characteristics of high speed and high unit output, and is mainly suitable for the production of hydrophobic filament chemical fiber fabrics with smooth surface.

SUNTECH can now provide super speed rapier looms, the maximum speed can reach 800rpm/min and other jacquard machine. It is suitable for weaving various widths and various types of fabrics. Using the famous components like Swiss Stäubli dobby shaft to make sure high quality machine. In addition, SUNTECH can also provide weaving factory with a wide range of fabric inspection machines, fabric rolling machine, beam trolley, cloth roll doffing trolley and automatic beam stacker. If you are interested in it, feel free to contact us.