With the rapid development of the textile industry, the improvement of production efficiency and product quality has become the core concern of every enterprise. Among the many production links, packaging, as the last link, is crucial to the improvement of production efficiency. Although the traditional manual packaging method is still used in small-scale production, in the face of the demand for mass production, automated equipment has gradually shown its unique advantages. The fully automatic roll packaging machine came into being to improve packaging efficiency and reduce costs. So, how does it improve efficiency compared to manual packaging?

Fully Automatic Fabric Roll Packing Machine

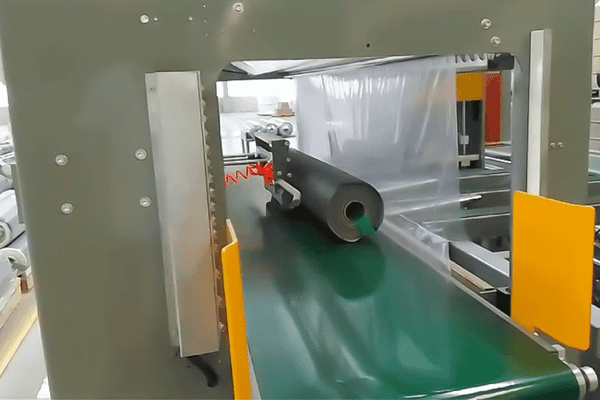

The fully automatic fabric roll packing machine is an efficient piece of equipment for fabric roll packing. Its basic working principle is to realize a series of processes such as winding, cutting, and packing of fabrics through an automated mechanical system. The built-in sensors and control systems of the machine can automatically adjust the working parameters according to the type, size, and quality of the fabric to ensure that the packaging effect of each roll of fabric meets the standards. In the workflow, the operation of the machine does not require manual intervention, which greatly improves efficiency and accuracy.

Efficiency Bottleneck of Manual Packaging

In the traditional manual packaging process, although the operators complete the packaging through experience, there are still many efficiency bottlenecks:

Time cost: Manual packaging usually requires a lot of manpower and time, and each step depends on the manual operation of the operator, which is not only slow but also prone to errors.

Human resource limitations: Manual packaging requires more labor, especially during peak periods, companies may face the problem of insufficient manpower, resulting in production delays.

Packaging consistency problem: Due to the different operating methods of each worker, the standardization and consistency of manual packaging are difficult to guarantee, and different packaging effects may occur, affecting product quality.

Fully Automatic Fabric Roll Packing Machine Improves Efficiency

Fully automatic Fabric Roll packing machine can greatly improve packing efficiency through the following aspects:

Increase Working Speed: Automated equipment can complete a series of complex packaging processes in a short time, greatly speeding up the overall operation speed of the production line.

Reduce Manual Operation Errors: Every link completed automatically by the machine is program-controlled, which can effectively avoid human operation errors and ensure that each packaging step is accurate.

Automated Data Recording and Tracking: Modern fully automatic roll packaging machines are equipped with intelligent control systems that can record and track the packaging information of each roll of cloth in real time, making it easier for companies to conduct quality management and traceability.

Advantages of Fully Automatic Fabric Roll Packing Machine

The emergence of fully automatic fabric roll-packing machines makes the packaging process more efficient and accurate, and brings the following advantages:

Improve production capacity: Automated equipment can greatly improve the work efficiency of the production line, reduce unnecessary waiting time and operation stagnation, and increase overall output.

Reduce raw material waste: Due to the accuracy of the fully automatic fabric roll packaging machine, it can ensure the optimal use of packaging materials, reduce waste, and reduce corporate costs.

Enhance packaging consistency: Each roll of fabric can be packaged according to the set standards, ensuring uniformity and stability of quality.

Fully Automatic Fabric Roll Packing Machine Improves Efficiency

The use of a fully automatic fabric roll packaging machine not only improves production efficiency but also significantly improves the overall benefits of the enterprise:

Cost savings: Although the initial investment of fully automatic equipment is large, in the long run, it can effectively reduce labor costs and raw material waste, and achieve cost savings.

Increase production capacity: Fully automatic equipment increases the operating speed of the production line, helping enterprises to produce more products in a limited time, thereby increasing output value.

Enhance market competitiveness: By improving production efficiency and product quality, enterprises can take the lead in fierce market competition.

Technological Development

The technology of fully automatic fabric roll packaging machines continues to advance. The integration of new technologies such as machine vision, sensor technology, artificial intelligence and data analysis has further improved the efficiency and accuracy of packaging. For example, the machine vision system can accurately detect the quality of fabrics, automatically judge defects, and ensure that the quality of each roll of fabric meets the standards.

Automatic Fabric Roll Packing Machine Development Trend

In the future, fully automatic fabric roll packaging machines will develop in a more efficient and intelligent direction. With the continuous innovation of technology, the machine will have stronger autonomous judgment capabilities, be able to adapt to more diversified packaging needs, and further improve production efficiency.

Conclusion

The fully automatic fabric roll packaging machine significantly improves the efficiency of the packaging process by increasing packaging speed, reducing human errors and ensuring packaging consistency, bringing higher productivity and lower operating costs to the textile industry. With the continuous advancement of technology, automation equipment will play a greater role in the future and help companies stand out in market competition.