Non woven fabric is a fabric type with its fibermesh formed by high polymer chips, staple fibers or filaments through non woven machine, then reinforced by the methods of spunlaced, needle punched, or hot rolled with final finish operations.

All the factors that influence the growth of rayon fibers have a greater or lesser impact on textiles that made from it, of which the non woven fabrics are influenced greatest. Here are the main 4 factors that influencing the growth of non woven fabrics production.

Population Growth

Non woven diapers attract a lot of love from young parents in recent years because of its high air permeability. In spite of the overall global fertility rate has declined significantly in recent years for various reasons compared to previous decades, the world population is expected to reach 8 billion by the end of this year according to a report released by the United Nations so that the important roles that nonwovens play in baby diapers field makes the population growth become one of the essential factors to have influence on non woven fabric productions. However, compared with the impact on other textile products in apparel industry by population growth, the impact on non woven fabric is much smaller if we don’t consider the applications of nonwovens in baby diapers manufacturing.

Partial Replacement of Natural Fibers

The partial replacement of natural fibers also has a greater impact on textiles, but not on non woven fabrics because of the largely dependent on rayon fibers for non woven fabrics production. Polypropylene fibers (62% of the total), polyester fibers (24% of the total) and viscose fibers (8% of the total) are the top 3 main materials in non woven fabrics production. Viscose fiber was the most used in the production of non-woven fabrics during 1970-1985. However, the application of polypropylene fibers and polyester fibers has begun to dominate in the past 5 years at sanitary absorbent materials and medical textiles field. Nylon was used in a large amount in the early non-woven production market, then the acrylic fibers began to be used in the market since 1998, especially in the field of artificial leather manufacturing.

Commercial Development of Rayon Fibers

Due to the lower cost and convenient applications of non woven fabrics in our daily life, many textiles have been replaced by non-woven products for knitting, plastic films, polyurea foam, wood pulp, leather, etc. It indicates the commercial development of rayon fibers and the professional application of non woven cloth promotes the growth of non woven cloth, especially the establishment of international economic treaties, which led to a growth in the trade of microfibers, composite fibers, biodegradable fibers and new polyester fibers, has a significant impact on nonwovens.

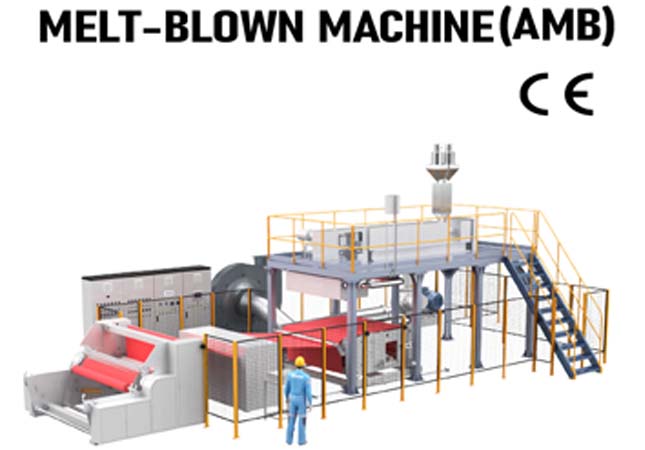

Development of Non Woven Machine

With the rapid development of the economy and technology, as an important part of the industrial field, non woven machine occupies a place in the market economy ,which increased the production efficiency of non woven fabrics. Conversely, has been forced to update with advanced technologies by impacting from larger demand for non woven fabrics.

In specific industries, strict requirements and standards for nonwovens are keys to meet demanding markets. SUNTECH air spunmelt lines steadily produce top quality nonwovens with strong filterability and air permeability, also provide you the best protection and safety. It can produce premium quality spunmelt nonwovens that applied in hygiene and medical industries, ultra soft and high-loft with strong filterability, excellent air permeability with breathing freshness, strong stability with high productivity.

Over 50 years of innovation, SUNTECH is a world-wide acting enterprise with decades of tradition and experience. We develop, produce and distribute high quality non woven machine based on digitization, automation and intelligence. Contact us now!