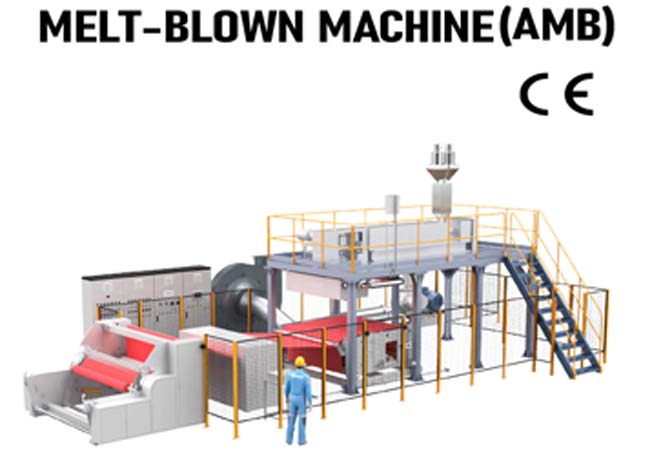

The COVID-19 epidemic has increased the global demand for non-woven masks in recent years so that the production of some large-scale machines used to produce non-woven fabrics, such as non woven fabirc slitting machine and meltblown non woven machine, has increased greatly correspondingly. However, operators who were familiar with the operation of small meltblown non woven machine in the past were often not used to operating large meltblown non woven machine, which resulting in operational problems that plagued the production process.

Here are some operating cautions of meltblown nonwoven machine as reference:

Running Sequence Of Meltblown Nonwoven Production Line

1. Temperature Rise

For a new meltblown system, it need all the equipment including screw extruders, melt filters, melt pipes, spinning pumps, melt-spinning manifoldes and drafting air heaters be synchronized warming up if it’s the first time for a meltblown system to rise temperature from a cold state. Also all equipment must be in a normal state during temperature rising process and the spinning system must in an off-line position.

1. Management During Temperature Rising

When the temperature reaches the set point, it requires the equilibrium holding time must be 0.5- hours to ensure that the melt in the system can be completely melted and can flow in a normal state. The set value is determined by the ambient temperature and the configured heating power, usually will take 3-4 hours for the melt-spinning manifold to rise temperature from a cold state for being ready for startup.

During the rising temperature process of the melt-spinning manifold, the oil stains that remains on the melt-spinning manifold, the melt pipeline, the hot air pipeline and the moisture in the thermal insulation layer will vaporize or evaporate, with some white smoke generated from these parts but will gradually decrease after about 30 minutes. This is a normal process but indicates an overheating, smoldering or open fire is happening to the meltblown system if the generated smoke is continuously increasing even turns its color into yellow or black and smells more intense, which is a dangerous signal, if not If handled in time, it will easily evolve into a fire accident.

2. Precautions

Therefore, there must be personnel monitoring when operating the machine, for carrying out a careful inspection when abnormality occurs. Also the operation can only be continued after troubleshooting. A certain number of dry powder fire extinguishers should be prepared in case of emergency.

In order to avoid the overshooting phenomenon in which the temperature greatly exceeds the set value during the heating process, we can adopt a step-by-step approach, that is, the temperature rise is set in stages rather than the one-step setting method. It can alleviate the overshooting phenomenon and shorten the transition spinning time after start-up.

Components

When the system reaches the working temperature, the preheated quick-load spinning assembly can be installed. The preheating temperature can be 30-50°C higher than the cabinet temperature or working temperature which is depend on the ambient temperature and installation skills. When adopting the preheating process, the quick-loading spinning assembly can be put into operation in about 1 hour.

For systems that using on-site assembled components, we can start to install the components and make preliminary adjustments when the temperature of the melt-spinning manifold reaches 160 °C and set a proper temperature for the melt-spinning manifold after all the spinning components are installed. It is crucial to check the air gap size of the spinning assembly during the heating period and before the actual working process start. The installation and heating process of a meltblown system that used on-site assembly components generally takes 4-6 hours.

Before the temperature of the system reaches the set value, the drafting airflow system should also participate in the operation to coordinate the spinneret temperature rise. We need to start the spinning pump to spin at low speed in time when it reaches the set temperature. The on-site assembly system also require a thermal adjustment of the packs according to the spinning state. Being sure to pay attention to the melt pressure controlling in the spinneret or in the spinning manifold after starting the spinning pump, which can avoid damage to the spinneret.