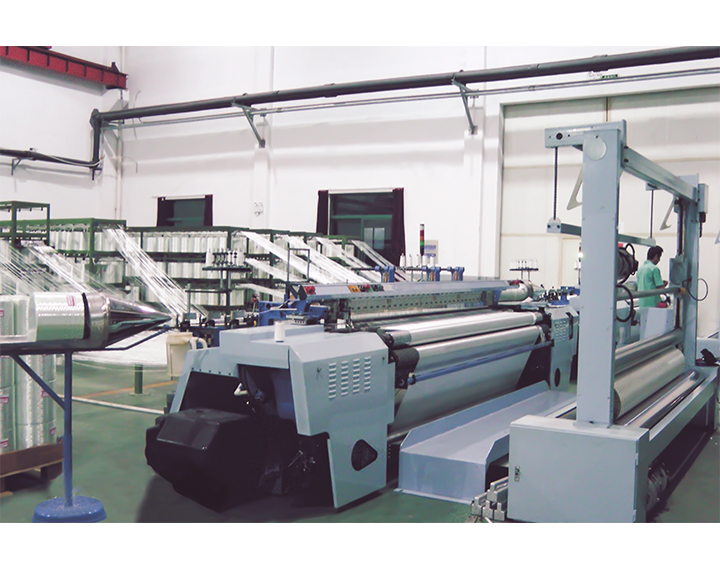

Glass fiber is an inorganic non-metallic material with high performance. Glass fiber rapier loom at SUNTECH is one of the hot and popular machine line to produce glass fiber.

Glass fiber’s wear resistance is very weak. Glass fibers are generally employed as reinforcing elements in composite materials, electrical insulating materials and thermal insulation materials, circuit substrates and other areas of the national economy.

Glass fiber cloth is usually utilized in the hand lay-up process, and the glass fiber reinforced material square cloth is largely used in ship hulls, storage tanks, cooling towers, ships, vehicles, tanks, and building structural elements. Fiberglass fabric is generally used in industry for: heat insulation, fire prevention and flame retardant. The material absorbs a lot of heat when it is burnt by a flame and may block the flame from passing through and isolate the air.

The difference between the material of fiberglass fabric and glass

There is minimal difference between the major ingredients of glass fiber cloth and glass, largely owing to the varied material needs during manufacturing, thus there are some variances in the formula. The silica percentage of flat glass is usually 70-75 percent , while the silica content of glass fiber is normally below 60 percent .

Glass is an inorganic substance that has been melted at high temperature (over 800 degrees, and everyday glass is commonly melted above 1100 degrees.), and no chemical changes will occur below the softening point temperature. Above the softening point temperature, it will merely soften, melt or degrade, and will not ignite.

Glass fiber fabric is manufactured by pulling glass into extremely fine glass filaments, and the glass filaments at this time exhibit high elasticity. The glass fiber is spun into yarn, and then woven into glass fiber fabric by a loom. Because the glass filament is exceedingly thin and the surface area per unit mass is extremely great, the temperature resistance performance is lowered. It's like melting a tiny copper wire with a candle.

But glass doesn't burn. The burning we can see is really the resin material placed on the surface of the glass fiber cloth, or the associated impurities to increase the performance of the glass fiber cloth. After pure glass fiber cloth or certain high temperature resistant coatings, it may be utilized to manufacture items such as refractory apparel, refractory gloves, and refractory blankets. However, if it is in close touch with the skin, the broken fibers will irritate the skin and it will be quite irritating.

Precautions

Generally, the diameter of ordinary glass fiber monofilament is more than 9-13 microns, and the glass fiber floating below 6 microns may directly enter the pulmonary duct, which can cause respiratory disorders. Therefore, great care should be taken, and most of them below 6 microns are imported. Professional masks must be worn throughout industrial procedures. If exposed often, it may be inhaled into the lungs and cause pneumoconiosis.

If glass fiber is on the body, those with terrible skin will be allergic and irritating, but normally not hazardous, and those with bad skin may develop little bags, which is an allergic phenomena. Just take some anti-allergic medication. .

If it is difficult to remove it off garments, pat it a few times in a breezy location. After washing it and drying it, it is easier to remove it by patting and batting with branches, etc., and pat it numerous times!

Having a specialized sales personnel with local market understanding and resources is expected of you from the beginning.

In order to reply to customer demands in a timely fashion, localized service and support will be essential

Ideally, the applicant should have relevant textile or nonwoven sector skills and understanding.