Rapier Weaving Machine is a kind of shuttleless loom which has a wide application. It can be used to weave different kinds of fabric like cotton, hemp, wool, silk, chemical fiber and so on. It can also be used to weave different widths of fabric, like 190cm, 220cm, 230cm, 250cm, 280cm, 300cm, 340cm, 380cm etc. Rapier weaving machine appeared from the year of 1925, which is designed to solve the problem of weft insertion for some weft yarns which are difficult to finish the weft insertion.

What’s the advantages of the rapier weaving machine?

1) Rapier weaving machine can be used for weaving the heavy fabric. If you want to weave heavy fabric, it is impossible for other kind of shuttleless loom to finish the weft insertion, because the weft yarns of the heavy fabric is too heavy, it’s hard to finish the weft insertion without the guiding of rapier loom.

2) Rapier weaving machine is suitable for weaving the wide width fabric. We could know that the width is the distance of weft insertion. If the width is too wide, which means the weft insertion has a long journey, it’s difficult to complete the weft insertion of wide width fabric without the guidance of the rapier.

Why to choose the rapier weaving machine from SUNTECH?

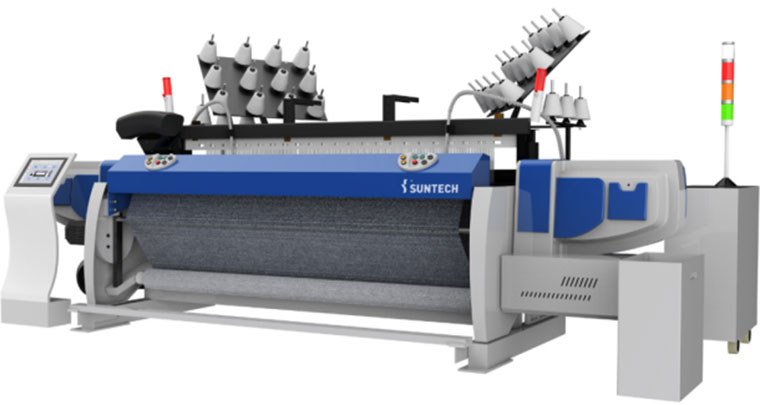

There is no doubt that what fabric manufacturer focus more is the machine speed. At present, the loom speed in China is generally around 500r/min, while SUNTECH has developed the ultrafast start rapier loom, model ST-ERL-808-ULTRAFAST, whose max speed can reach 800rpm/min, even stable speed is at 550~650rpm, which can compete with Picanol Optimax-i.

Below is the features and pictures of ST-ERL-808-ULTRAFAST for your reference:

(1) Wide Application:

It is not only suitable for normal fabric weaving like cotton, hemp, wool, silk, chemical fiber and etc, but also applicable for glass fibre, metal fibre, basalt fiber and other special industrial fiber fabric production.

(2) Super Speed:

Maximum speed up to 800rpm, stable speed can reach 550-650rpm. Compete with Picanol Optimax-i

(3) Alloy Steel Guide Rail:

Ensure the stability of rapier gripper and rapier tape under high speed operation, the wear resistance and service life is 5 times that of traditional aluminum alloy guide rail.

(4) Heavy Loom Construction:

Heavy duty special steel material and solid crossgirder & base ensure loom stability at high speed.

(5) Super motor:

The motor instantaneous burst torque reaches 3000Nm, making the loom speed reach the rated speed immediately after starting up. The motor can run for a long time without being affected by heat

(6) Intermediate Conjugate CAM Weft Battening:

Enhance the rigidity of the weft battening mechanism, increases the weft battening force, and the motion balance is beneficial to high-speed weaving. Motor drive imported from Spain.

(7) High Efficiency:

Compared with traditional looms, power consumption can be saved by 15%-20% at the same speed.

SUNTECH equips two major elements required by rapier looms.

1) Stability: The weft insertion method driven by the rapier will interweave the warp and the weft more stably.

2) Speed: Now that the common speed of rapier looms is 500rpm/min, SUNTECH has been able to reach the maximum speed at 800rpm/min, and the stable speed is also at 550~650rpm/min

SUNTECH has more than 50 years experience in textile machinery manufacturing, and has more than 5,000 customers using our machines all around the world. There is no doubt that SUNTECH can offer professional suggestion and suitable rapier weaving machine for you according to your actual requirement.