Artificial intelligence(AI) technology is a key differentiator for today’s world and is applied to almost every domain, such as AI robots, self-driving vehicles and the AI assistant in our mobile phones. AI can transforming the ways we are living, which is a key enabler for next-generation services transformation. Also, the textile industry cannot optimized itself without the AI-based visual inspection defects detection technology for the fabrics.

Introduction to AI-based Visual Inspection Defects Detection

AI-based visual inspection defects detection is a process of using computer vision algorithms to automatically inspect fabrics for defects, also the products defects if it’s in other industries. It can be used to replace or supplement traditional manual fabric inspection methods.

Fabric defects detection is the process of identifying defects in the fabrics, which is done manually all the time, under the aid of automated methods, such as fabric inspection machine and defects image records automatically.

Benefits of Implementing AI-based Visual Inspection Defects Detection

There are many benefits of implementing AI-based visual inspection defects detection in manufacturing and the textile industrial settings. Perhaps the most obvious benefit is that it can help to improve quality control by catching errors and defects that might otherwise go undetected. Additionally, AI-based visual inspection defects detection technology can help to improve efficiency by reducing the need for manual inspection of fabrics, for freeing up workers for other tasks, or simply allow production to move more quickly. AI-based visual inspection defects detection technology can help to create a more consistent fabrics, as human inspectors may vary in their ability to catch small defects. Finally, using AI for visual inspection defects detection can help to create a safer work environment, as it eliminates the need for workers to be in close proximity to potential hazards such as moving machinery.

How Does AI-Based Visual Inspection Defects Detection Work?

AI-based visual inspection and defects detection is a process that uses artificial intelligence to identify fabric defects by analyzing fabric defects images or by being installed onto a fabric inspection machine to join the fabric inspection process by recording and marking fabric defects and uploading the data to cloud system for operators checking. The goal of this process is to improve the quality of fabrics and the accuracy of fabric defects inspecting, and to reduce the cost of manufacturing.

Examples of AI Based Visual Inspection Defects Detection Technologies

There are many different types of AI-based visual inspection defects detection technologies available on the market today. Some of the most popular and widely used include:

1. Machine Learning

This type of AI technology is used to create models that can learn from data and improve over time. This is often used for things like facial recognition or object classification.

2. Computer Vision

This type of AI technology is used to process and interpret images. This can be used for things like automated inspection or object detection.

3. Natural Language Processing

This type of AI technology is used to process and understand human language. This can be used for things like chatbots or automatic translation.

SUNTECH Automatic Camera Inspection System

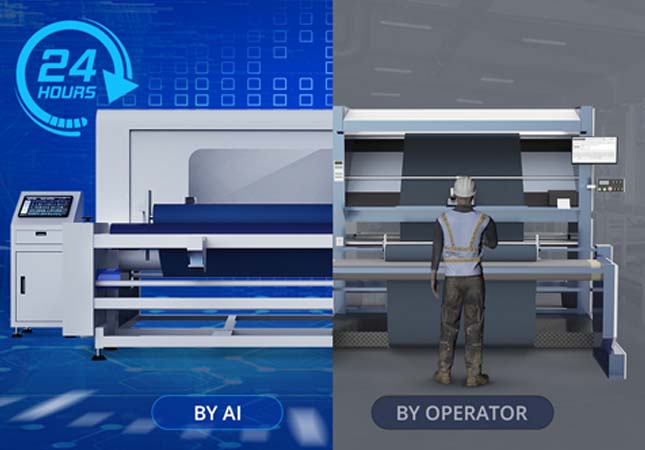

ST-ACI-I is an automatic camera inspection system from SUNTECH, which can be applied onto various kinds of fabric inspection machines. It uses the AI visual inspection defects detection technology, and is suitable for a wide range of fabrics, from tension-sensitive lycra fabrics to stable woven. The fabric will be detected with the camera inspection system, with recording the fabric information synchronously by the computer. ST-ACI-I truly achieves the 24-hour unmanned fabric quality testing.

Main Functions of ST-ACI-I

l High Intelligence, 24 Hours 100% Attention

l Reduce dependence on people and ensure stable production

l High Efficient, Speed 60m/min

l Comparing with manual inspection 10-15m/min,4 times increased

l Can replace 3-5 inspector, greatly save the labor cost

l High Precision, Inspection Rate Upto 90%

l Comparing with manual inspection rate, 30% increased

l Convenient Scalability, ERP/SAP Compatible

Challenges Associated With AI Based Visual Inspection Defects Detection

There are several challenges associated with AI-based visual inspection and defects detection. First, it can be difficult to train the system to distinguish between different types of defects. Second,AI-based systems can be susceptible to false positives, meaning that they may flag an inspection as defective when there is actually no defect present. Finally, AI-based systems can be expensive to implement and maintain.

What Companies are Using AI for Visual Inspection?

Companies across a variety of industries are using AI for visual inspection in order to streamline their production process and improve the quality of their products. Automotive companies are using AI to inspect vehicles for defects, food and beverage companies are using AI to inspect items for contaminants, and many other companies are using AI to perform visual inspections in a variety of settings.

By incorporating AI into their inspection process, companies are able to improve the accuracy and efficiency of their visual inspection. In addition, AI-based visual inspection can be conducted more frequently than human-based inspection, which allows for more consistent quality control. Overall, AI-based visual inspection is helping companies improve the quality of their products while also reducing costs associated with defective items.

Conclusion

AI-based visual inspection and defect detection is becoming increasingly popular as a reliable way to identify defects in products. By leveraging artificial intelligence technology, this process eliminates reliance on manual inspections and allows for improved accuracy and objectivity. This type of system can detect minute details that would go undetected by traditional methods, ensuring a high quality product every time. With the development of AI technology continuing to improve, it seems likely that applications such as this will become even more commonplace than they are today.