The warp yarns of several warp beam are sized (or not) and merged to form a sizing beam (without sizing they are called warp beams), or the warp yarns are directly processed by slitting and warping to obtain a warp beam. The sizing and warp beams are processed through the heald to obtain the weaving beam.

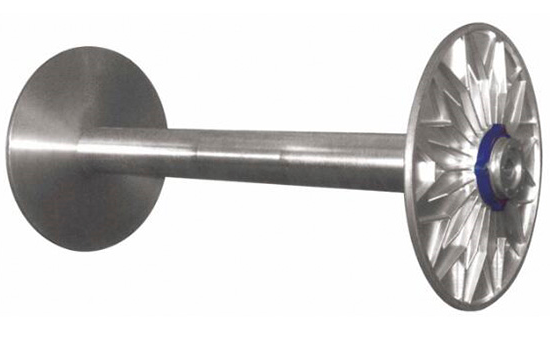

When weaving fancy fabrics, multiple weaving beams are needed to supply ground warp yarns, wool warp yarns and pattern warp yarns, and the corresponding weaving beams are called ground warp weaving beams, wool warp loom beam and pattern warp weaving beams. The number of wound warp beams is equal to the total number of warp beams of the fabric. Its size determines the warp capacity of the volume, which should be adapted to the matching loom. The main dimensional parameters are the width of the weaving beam, the diameter of the side plate, the diameter of the shaft tube, etc.

Warping

The yarn is wound evenly onto the warp beam with a certain tension according to the number and length required for the weaving process, which is called warping. It is the preparation process of warp knitting production, equivalent to the weft knitting yarn. The quality of the whole warp has a great impact on the production of warp knitting, practice has proved that about 70% of the defects in the warp knitting is due to the whole warp is not good and caused by the industry has a common saying: "seven points of the whole warp, three points of weaving" is a more graphic description of the importance of the whole warp.

Segmented warping

The warp yarns are wound equally on small narrow warp beam, and then a number of small narrow warp beam are threaded side by side on a core shaft to form a weaving beam. Then it is installed to the warp knitting machine for weaving.

Features: high production efficiency, small footprint, convenient transportation and operation, relatively economical, can adapt to the requirements of multi-species and multi-color yarns, with the development of segmented warping technology, segmented warping to high-speed, intelligent tension control, high-precision copy direction, the current maximum line speed up to 1200 m / min.

Shaft warping

Shaft warping is the simultaneous winding of yarns from one comb of a warp knitting machine onto a warp beam and directly onto the warp knitting machine for weaving. It is generally used in multi-comb warp knitting machines with fewer yarn roots on the comb. So the shaft warping is sometimes also called "flower warp shaft warping". Application: Suitable for warping of fancy yarns with a small number of roots, not suitable for warping of warp yarns with a large width. From the initial cam control of the warp beam, the warp beam is now controlled by a servo motor and can be hemmed intelligently.

Warping requirements

1. Uniform and consistent starting tension and moderate size.

The tension between warp yarns is uniform (otherwise "straight" defects will be formed); the tension of each warp yarn is uniform from beginning to end (otherwise there will be changes in the density of different segments of the warp knitting blank); the size of the warping tension is moderate (too small to warp, too large to affect the elasticity and strength of the yarn, and may even cause serious consequences of warp burst), the tension value The tension value is generally 0.09-0.13cN/dtex, which varies with the performance of the yarn.

2. Eliminating warp faults to improve yarn weaving performance.

Such as hairy yarn detector, oiling the yarn to improve its gathering, smoothness, softness and anti-static properties, thus improving the weaving performance.

3.The same warp to use the same batch of yarns.

Differences in tension, shrinkage and dyeing properties of different batches of filaments cause uneven warp surfaces, which can affect product quality.

4.Choose the appropriate warping speed

The same set of warp beams should be warped at the same speed and the warping speed should not be changed in the middle.