With the development of technology, AI and intelligence technology are used more and more widely in the industry. Visual inspection defects technology, also known as visual inspection systems or machine vision systems, is one of the most famous technology, widely used in various industries, such as manufacturing, automotive, electronics, pharmaceuticals, food and beverage, and packaging, to ensure the quality and reliability of products.

A General Introduce of the Visual Inspection Defects Technology

There is something about the visual inspection defects technology.

1. The consist of visual inspection defects technology

Visual inspection defects technology involves the use of cameras, sensors, lighting, and image processing algorithms to capture and analyze images or videos of products or materials in real time. The images or videos are then processed by specialized software that identifies defects, inconsistencies, or abnormalities in the products or materials based on predefined criteria or specifications. If any defects are detected, the system can trigger alerts or take appropriate actions, such as rejecting the defective product, sorting it out, or sending it for further inspection or repair.

2. Key advantage of visual inspection defects technology

One of the key advantages of visual inspection defects technology is its ability to perform non-contact and non-destructive inspection, which eliminates the need for human intervention and reduces the risk of damaging the products or materials during the inspection. It also provides high accuracy and repeatability, as the system can consistently detect defects with high precision, even in complex or challenging environments. This technology also offers high speed and efficiency, as it can inspect products or materials at high speeds without compromising the quality of the inspection.

Visual inspection defects technology can detect a wide range of defects, such as scratches, cracks, dents, stains, misalignments, color variations, missing components, and other surface or structural abnormalities. It can also perform various inspection tasks, such as dimensional measurement, character recognition, pattern recognition, and color verification. This makes it a versatile solution for inspecting different types of products, including automotive parts, electronic components, pharmaceutical tablets, food packaging, and more.

3. Some techniques used in the visual inspection defects technology

There are several types of visual inspection defects technology available, depending on the specific application requirements. Here are some commonly used techniques.

(1) 2D visual inspection

This method employs 2D cameras and advanced image processing algorithms to capture and analyze 2D images of products or materials, which is ideal for inspecting flat or planar objects, such as printed circuit boards, labels, or glass sheets. 2D visual inspection utilizes various features such as brightness, contrast, texture, edge detection, and pattern recognition to detect defects with precision and accuracy.

(2) 3D visual inspection

It’s also called cutting-edge 3D cameras or laser scanners to capture and analyze 3D images of products or materials. It provides detailed and precise information about the shape, depth, and surface characteristics of objects, making it suitable for inspecting complex or irregularly shaped items, such as machined parts, molded components, or assembled products. 3D visual inspection relies on features such as height variation, surface roughness, shape deviation, and volume measurement to detect defects with high resolution and accuracy.

(3) Thermal visual inspection

This method employs advanced thermal cameras to capture and analyze the thermal or heat signatures of products or materials, suitable for inspecting objects that generate heat, such as electronic components, machinery, or food products. Thermal visual inspection relies on temperature variation, heat patterns, or hotspots to detect defects that may indicate overheating, thermal stress, or other abnormalities.

(4) X-ray visual inspection

The use of utilizes advanced X-ray or computed tomography (CT), helps scanners to capture and analyze X-ray images of products or materials. It is suitable for inspecting objects that are opaque or difficult to inspect using visible light, such as metal parts, composite materials, or packaged goods. X-ray visual inspection relies on features such as density variation, voids, foreign objects, or internal structures to detect defects with exceptional accuracy and precision.

(5) Note

Please be aware that X-ray visual inspection requires specialized equipment and trained personnel to ensure safety and compliance with applicable regulations. Proper precautions and guidelines should be followed when implementing X-ray inspection in any industrial setting.

How the Visual Inspection Defects Technology Be Used in the Textile Industry

Visual inspection defects technology plays a critical role in the textile industry by providing a reliable and efficient method to detect and identify defects in textiles during various stages of production. This technology utilizes advanced imaging systems, image processing algorithms, and automation techniques to inspect textiles for defects, thereby ensuring that only high-quality products are delivered to customers.

1. Fabric manufacturing process

One of the key areas where visual inspection defects technology is utilized in the textile industry is during the fabric manufacturing process, which includes weaving and knitting. Weaving and knitting machines produce large volumes of fabric at high speeds, making manual inspection impractical and time-consuming. Visual inspection defects technology utilizes high-resolution cameras and sophisticated image processing algorithms to capture and analyze images of the fabric in real time as it is being woven or knitted. These systems can detect defects such as holes, broken threads, slubs, snags, or other irregularities with high accuracy. When defects are detected, the system can trigger alerts or automatically stop the machine, allowing for prompt corrective actions to be taken, minimizing the production of defective fabric, reducing material waste, and improving overall fabric quality.

2. Dyeing and printing processes

Visual inspection defects technology is also widely used in the dyeing and printing processes in the textile industry. After the fabric is woven or knitted, it goes through dyeing and printing processes to add color and patterns. Visual inspection defects technology can inspect the fabric for color variations, streaks, smudges, misprints, or other defects that may impact the appearance and aesthetics of the finished textile products. By identifying defects early in the process, visual inspection defects technology helps to minimize rework, reduce material waste, and ensure consistent color and print quality across textile products, enhancing their visual appeal and customer satisfaction.

3. Cutting and sewing processes

Another area where visual inspection defects technology is employed in the textile industry is in the cutting and sewing processes. Once the fabric is dyed or printed, it is cut into various pieces to be assembled into final textile products such as garments or home textiles. Visual inspection defects technology can inspect the cut pieces of fabric for defects such as uneven edges, mismatched patterns, or incorrect measurements. This ensures that only defect-free pieces are used in the sewing process, resulting in high-quality finished products with accurate fit, alignment, and appearance.

4. Other stages of textile production

Visual inspection defects technology is also utilized in other stages of textile production, such as the inspection of finished textile products for defects before they are packaged and shipped to customers. This can include inspecting garments, home textiles, or other textile products for defects such as loose threads, missing buttons, zippers, snaps, or other manufacturing defects. Visual inspection defects technology ensures that only defect-free products are shipped to customers, reducing returns, recalls, and customer complaints.

5. Inspection of raw materials

Moreover, visual inspection defects technology is used in the inspection of raw materials, such as yarns or fibers, before they are used in the textile manufacturing process. This can include inspecting yarns for defects such as knots, uneven thickness, or foreign particles, or inspecting fibers for defects such as clumps, contaminants, or inconsistencies. Early detection of defects in raw materials helps prevent the production of defective textiles, reduces material waste, and ensures the quality of the final products.

6. More usage in the textile industry

In addition to defect detection, visual inspection defects technology can also be used for other purposes in the textile industry. For example, it can be used for pattern matching, where the system compares the actual pattern of the textile product with the expected pattern, ensuring that the patterns are aligned correctly. This is particularly important in industries where precise pattern alignment is crucial, such as in the production of striped or plaid fabrics. Visual inspection defects technology can also be used for label inspection, where the system verifies the presence, position, and accuracy of labels or tags on textile products, ensuring compliance with regulatory requirements, branding guidelines, and customer expectations.

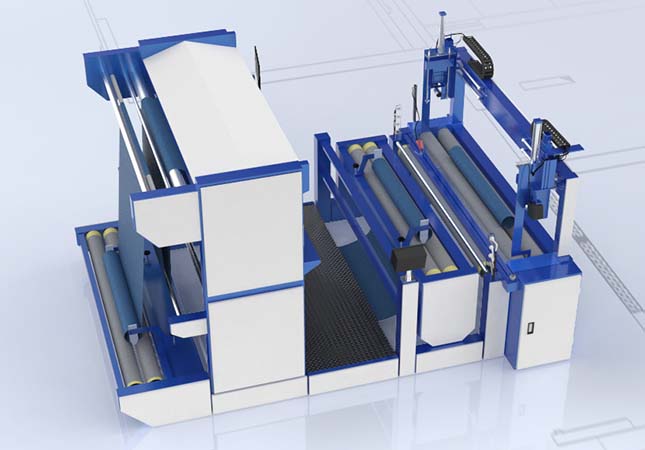

SUNTECH ST-ACI-I Automatic Camera Inspection System ( for Fabric Inspection Machine )

SUNTECH automatic camera inspection system is versatile and can be integrated with various types of fabric inspection machines, making it suitable for a wide range of fabrics, from tension-sensitive lycra fabrics to stable woven materials.

l The camera inspection system detects fabric defects and records fabric information synchronously with the software and computer, enabling 24-hour unmanned testing for improved efficiency.

l The system's high intelligence allows for 100% attention and reduces dependence on human inspection, ensuring stable production and minimizing errors.

l With a speed of 60m/min, the system is significantly more efficient compared to manual inspection which typically averages 10-15m/min, resulting in a four-fold increase in productivity.

l The system has the potential to replace 3-5 inspectors, resulting in substantial labor cost savings.

l The high precision of the inspection system results in an inspection rate of up to 90%, which is a 30% increase compared to manual inspection rates, ensuring higher quality fabric output.

l The system is conveniently scalable and compatible with popular ERP/SAP systems, allowing for seamless integration into existing production processes and workflows.

l The use of advanced vocabulary and non-duplicate language enhances the quality of communication and conveys the advantages of the system in a clear and professional manner.

Conclusion

Visual inspection defects technology, which is high-tech and helpful, offers numerous benefits to textiles. SUNTECH, which is one of the most popular textile machinery suppliers in the world, buying the products from it would be an ideal choice for textile manufacturers.

SUNTECH textile machinery,as one of the leading textile machiner manufacturers, has always adhered to the value proposition of sustainable development, which is to help our customers achieve higher output with fewer resources by leveraging technology. We aim at empowering customer efficiency and productivity improvement, optimizing resource utilization,providing the textile industry machines to the whole world, such as fabric cutting machine,inspection machine,fabric inspection machine supply,automatic packing machine,auto packing machine,trolley lift system, fabric sample cutter machine, fabric roll cutting machine etc.