There are many types of weaving machine. According to the weft insertion method of weaving, looms can be divided into two categories: shuttle looms and shuttleless looms.

Shuttle looms are weaving machines that use traditional shuttles (wood or plastic) for weft insertion. The shuttle is large and heavy. The machine has large vibration, high noise, slow speed and low efficiency. Due to these disadvantages, shuttle looms had been gradually phased out in the market. In contrast, Shuttleless looms have quickly occupied the loom market with their advantages of light weight, low vibration, low noise, high speed and high efficiency.

Types of shuttleless weaving machine

The weft insertion methods of shuttleless looms are various, including rapier, jet (air jet and water jet), projectile, multi-shed (multi-phase) and weaving.

1. Rapier weaving machine: Use rigid or flexible rapier heads and belts to clamp and guide the weft. In addition to being suitable for weaving plain and textured fabrics, rapier looms are characterized by easy color changing, suitable for multi-color weft fabrics, and are suitable for the production of yarn-dyed, double-layer fleece fabrics, terry fabrics and decorative fabrics.

2. Air-jet weaving machine: the weft yarn is pulled by the jetted compressed air flow, and the weft yarn is brought through the shed. Air-jet looms are characterized by high speed and high labor productivity, and are suitable for the production of plain and textured fabrics, fine and extra-high-density fabrics and fabrics in large batches.

3. Water jet weaving machine: Using water as the weft insertion medium, the jet water flow produces frictional traction on the weft yarn, so that the weft yarn on the fixed bobbin is introduced into the shed. The water jet loom has the characteristics of high speed and high unit output, and is mainly suitable for the production of hydrophobic filament chemical fiber fabrics with smooth surface.

4. Gripper weaving machine: The weft is held by a small gripper with a clip, and the weft is projected. The projectile loom has the advantages of stable weft insertion, excellent fabric quality, and few weft threads. It is suitable for the production of multi-color weft fabrics, fine, thick and dense fabrics and wide fabrics.

Performance of Shuttleless weaving machine

The common basic feature of the four types of shuttleless weaving machine is to separate the weft yarn package from the shuttle, or to carry only a small amount of weft yarn to replace the large and heavy shuttle with a small and light weft inserter, which provides advantages for high-speed weft insertion. In the supply of weft yarn, the bobbin package is directly used, and it enters the weft insertion mechanism through the weft storage device, so that the loom can get rid of the frequent weft replenishment action. Therefore, the use of shuttleless weaving machine is of great significance for increasing fabric varieties, adjusting fabric structure, reducing fabric defects, improving fabric quality, reducing noise and improving working conditions. The speed of shuttleless looms is high, and the efficiency is usually 4-8 times higher than that of shuttle looms. Therefore, the application of shuttleless looms in a large area can greatly improve labor productivity.

Due to the increasingly perfect structure of shuttleless weaving machines, a wide range of materials are selected, and the processing accuracy is getting higher and higher. Coupled with the development of world science and technology, electronic technology and microelectronic control technology have gradually replaced mechanical technology. The manufacture of shuttleless looms is a combination of metallurgy, machinery, electronics, chemical engineering and fluid power. It’s a high-tech product integrating technology and textile technology.

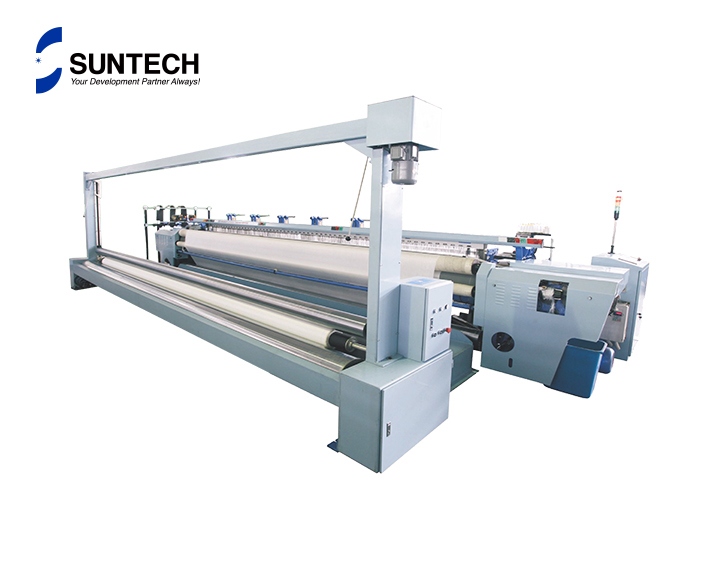

As a Weaving Machine manufacturer, SUNTECH provides the most advanced solutions for all kinds of weaving machines. If you want to purchase weaving machines or get more information about them, don’t hesitate to click SUNTECH website.