No matter material handling equipment, or textile machine, they all have its own origin and develop history. The treadle-operated spinning wheel is a kind of spinning machine which appeared after the emergence of hand spinning machine, it is developed on the basis of hand spinning machine with improved in the structure and has same functions as hand spinning machines. The motive power that drive this kind of spinning wheel is not from hands but feet,that is pressing on the treadle to transform the force through treadle, screws and crank and other transmission parts to make the wheel and spindle do continuous circular motion. Thus, the spinner's right hand, which was used to shake the rob on hand spinning wheel, was freed and her two hands were able to do spin or thread work at treadle-operated spinning wheel.

The treadle-operated spinning wheel not only makes up for the inconvenience of the hand spinning wheel that can only use one hand to spin and the difficulty of controlling the fine and short fibers and the kink problems of fibers during spinning process, which finally result in uneven yarn thickness problems, but also greatly increased the production efficiency.

Earliest Appearance

We are still not sure about the earliest appearance of the treadle-operated spinning wheel. In the exist known reference, the earliest reference that related to it is a drawing of Liu Xiang's "Lie Nu Zhuan · Luo-Tao Ying" by Gu Kaizhi, a famous painter from the Eastern Jin Dynasty in the 4th to 5th centuries AD. In Wang Zhen's "Nongshu" in the Yuan Dynasty, Xu Guangqi's "Nongzheng Quanshu" in the Ming Dynasty, and Chu Hua's "Kapok Spectrum" in the Qing Dynasty, there were also three-spindle spinning wheels and five-spindle spinning wheels, proving that The treadle-operated spinning wheel has been widely used since the Eastern Jin Dynasty.

Working Principle

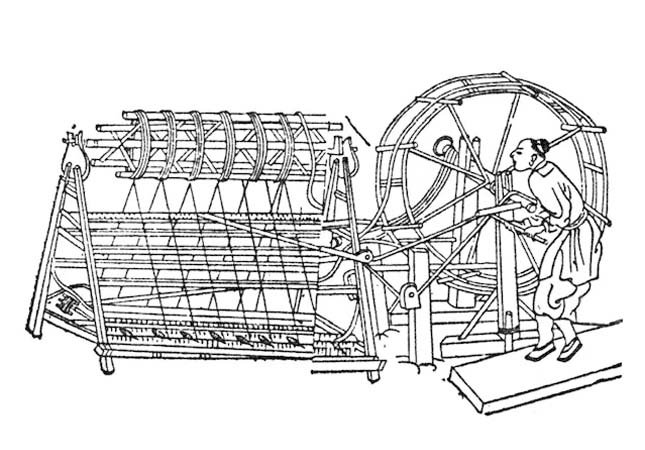

According to the pictures of treadle-operated spinning wheels drawn in ancient books, all kinds of spinning wheels are basically the same in shape and structure,which are all composed of spinning part and treadle part, except for the diameter of rope pulley and the number of spindles. The spinning mechanism of treadle-operated spinning wheel is similar to the hand spinning wheel, with spindles, rope pulley and ropes and other parts; the treadle mechanism is consist of cranks, treadles, screw and other parts.

The crank is mounted on the shaft of the rope pulley and is connected with the left end of the lower pedal rod by a short connecting rod. The right end of the treadle rod is connected with the screw. When the left and right sides of the pedal rod are alternately stepped on by both feet, the power arm of the pedal rod with the fulcrum of the screw as the boundary rotates in a conical trajectory in the opposite direction, drives the rope pulley and the spindle to rotate counterclockwise through the crank to complete the spinning work.

The diameter of the rope pulley on the spinning wheel and the number of spindles are determined by the fibers being spun. For hemp fibers that do not need to be drafted, the wheel diameter can be increased as much as possible and the number of spindles can be as many as five. However, the spindle speed and number of spindles during cotton spinning are limited by the sufficient drafting conditions of the fibers. It can not be too high so that the wheel diameter is small with maximum 3 spindles . Huang Daopo reformed the spinning wheel to make it suitable for spinning cotton by starting change the wheel diameter and the number of spindles. The "Nong Shu" divided the spinning wheel into a kapok spinning wheel for cotton spinning and a small spinning wheel for hemp spinning also for this reason.