Definition Of Material Handling Equipment Manufacturing Industry

Material handling equipment manufacturing industry(also known as hoisting and transporting equipment industry) refers to the manufacture of mechanical equipment , vehicles or their special accessories for conveying, handling, stacking, lifting, loading and unloading in warehouse, factories, platforms and other sites.

It was called hoisting and transporting equipment(machinery) that adopted in China in the 1950s. Then change the name to material handling equipment, which is adapted internationally, after 1980s when the domestic industry began to integrate with international standards. In 2011, the National Bureau of Statistics reclassified the national economic industry so it has its formal name as "material handling equipment".

Analysis of Material Handling Equipment Industry

1. Industrial Chain

Steel, castings, forgings and non-ferrous metal materials are the most important raw materials in the production of material handling equipment. Additionally, motors, hydraulic parts, tires and other important parts in the material handling equipment manufacturing industry. The quality and cost of material handling equipment manufacture can be affected if there is any change in upstream raw materials industry. Material handling equipment industry is closely related to most of the important industries that affect the nation economy,it is the supporting products of real estate construction, port and wharf, energy construction, transportation construction, mechanical processing and other industries. Therefore, the development of material handling equipment industry depends on the development of various sectors of the national economy.

2. Supplier Bargaining Power Analysis

The main raw materials of material handling equipment is steel, which accounts for a large amount of the total cost of a material handling equipment so that the price of steel directly affects the gross profit of material handling equipment. Due to the sufficient supply of domestic steel, material handling equipment manufacturers have a strong bargaining power for them, same as the electric motors, hydraulic parts and related parts, the price of them charge a certain proportion in the whole cost of material handling equipment and the related enterprises also have strong bargaining power for them because of the large number and small scale of enterprises producing these supporting parts in China, However, now in the field of high-end parts and components, such as hydraulic parts, we still rely on importing and the bargaining power of its’ manufacturers is relatively weak.

3. Purchase Negotiation Power Analysis

The downstream demand industries of material handling equipment industry mainly include large-scale infrastructure construction, energy industry (including electric power, nuclear energy, wind energy, petroleum and other industries), real estate industry, petrochemical industry, storage and logistics industry, shipbuilding industry, metallurgy industry, machining industry, aviation industry and so on. In the production process of these industries, material handling equipment is a necessary equipment with a stable demand, and some large enterprises have certain pricing power because of the high concentration of material handling equipment industry. However, the customers in material handling equipment commonly purchase a large amount and there is a fierce competition among enterprises in this industry, also there is a homogeneity problem of China material handling equipment industry, the differentiation between products and services is not obvious, which result in the difficulty in bargaining with customers.

4. Existing Enterprise Competition Analysis

The basic competition of the domestic material handling equipment market is the high-end market is mainly occupied by multinational enterprises, and the domestic key large enterprises have also obtained some markets in some specific fields. The participants in the middle market include large domestic enterprises and a few small and medium-sized enterprises with excellent manufacturing technology or high management level. Many small enterprises with weak technology and poor management, which lack product innovation and the product quality is not good for achieving a high product added value and results in poor economic benefits. They are in the low-end market of the industry, the competition is intense.

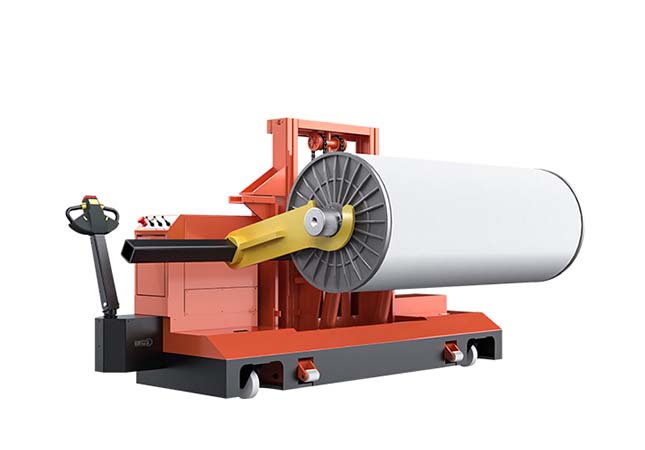

Currently, there are many brands of material handling equipment sold in the market. Among them, SUNTECH is one of the best material handling equipment suppliers, SUNTECH material handling equipment consists of Beam/Batch Lift&Transport Truck and Hydraulic/Motorized Trolleys. Especially for fully electric warp beam trolley, it is the kind of material handling equipment that suitable for various loom of width 1.7-3.4m, also the maximum loading capacity can up to 2500 kg. With this fully electric system of material handling equipment, you can increase the work efficiency by at least 50%. Besides, with maintenance free gel battery, you can also save at least 30% maintenance cost. SUNTECH is also capable of providing customized solutions to meet your different requirements and demands for diverse material handling equipment. We promise you the local agent& service support and engineer technical assistance to help you install the machines. So don't hesitate to grab the opportunity to enjoy SUNTECH handling equipment right now!