The fashion industry, once synonymous with rapid consumption and waste, is undergoing a significant transformation. This change is largely driven by advancements in manufacturing processes that prioritize sustainability and competitiveness. As global awareness of environmental issues grows, so too does the demand for fashion that is both eco-friendly and affordable. Companies that embrace these new manufacturing techniques are not only reducing their environmental footprint but also gaining a competitive edge in a crowded marketplace.

The Rise of Sustainable Fabrics

One of the most impactful changes in the manufacturing process is the shift towards sustainable fabrics. Traditional materials like cotton and polyester have long dominated the industry, but their production comes with a high environmental cost. Cotton, for instance, requires vast amounts of water and pesticides, while polyester is derived from petroleum, contributing to pollution and carbon emissions.

In response, the industry is increasingly turning to sustainable alternatives such as organic cotton, recycled polyester, and innovative materials like Tencel and Piñatex. These materials are produced with significantly less environmental impact, often using renewable resources and reducing waste. Moreover, their growing popularity reflects a shift in consumer values, with more people seeking out fashion that aligns with their environmental concerns.

Innovations in Production Techniques

Beyond materials, the methods of producing garments have also evolved. Traditional manufacturing processes are resource-intensive, often involving harmful chemicals and excessive water usage. In contrast, modern techniques such as digital printing, 3D knitting, and laser cutting offer more sustainable alternatives.

Digital printing, for example, reduces the need for water and chemicals by directly applying dyes to fabrics with precision, minimizing waste. Similarly, 3D knitting allows for the creation of garments with little to no fabric waste, as pieces are knit to shape rather than cut from larger fabric rolls. Laser cutting also enhances efficiency by reducing material waste and allowing for intricate designs without the need for excessive manual labor.

These innovations not only reduce the environmental impact of production but also enable faster, more flexible manufacturing processes. This agility is crucial in a market where trends change rapidly, allowing brands to quickly respond to consumer demands and reduce overproduction.

The Role of Circular Economy Models

The shift towards a circular economy is another key factor in the fashion industry's transformation. In a linear economy, resources are extracted, used, and then discarded. In contrast, a circular economy seeks to keep resources in use for as long as possible, extracting maximum value before recovering and regenerating products and materials at the end of their life cycle.

Many fashion brands are now embracing circular models by designing for durability, reparability, and recyclability. Clothing rental services, resale platforms, and take-back programs are becoming increasingly popular, allowing consumers to extend the life of their garments and reduce waste. For manufacturers, this shift requires rethinking product design, materials selection, and end-of-life considerations.

Enhancing Competitiveness Through Sustainability

Sustainability is not just a moral imperative; it is also a powerful competitive advantage. Consumers today are more informed and discerning, often favoring brands that demonstrate a commitment to environmental and social responsibility. By adopting sustainable manufacturing processes, companies can differentiate themselves in the market, building stronger brand loyalty and attracting new customers.

Moreover, sustainable practices often lead to cost savings in the long run. Efficient use of resources, reduction in waste, and energy-saving technologies can all contribute to lower operational costs. These savings can be passed on to consumers or reinvested in further innovation, driving long-term competitiveness.

The transformation of the fashion industry through sustainable manufacturing processes is a testament to the industry's ability to adapt and innovate in the face of global challenges. As brands continue to explore new materials, techniques, and business models, they are not only reducing their environmental impact but also positioning themselves for success in a more conscious and competitive market. The future of fashion is one where sustainability and competitiveness go hand in hand, offering a promising path forward for both the industry and the planet.

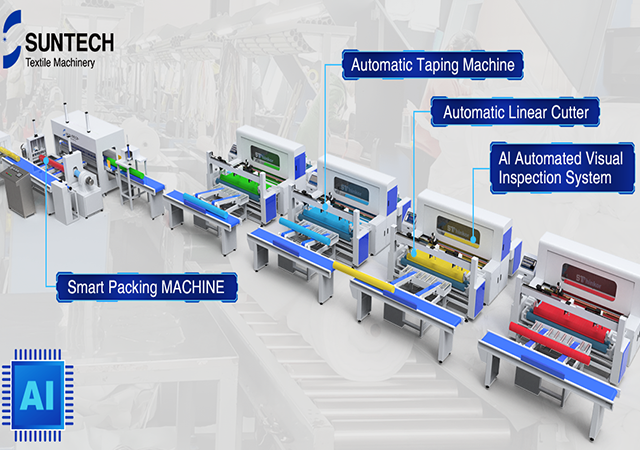

SUNTECH Textile Machinery has been dedicated to the development, production, and distribution of top-quality textile machinery since its establishment. With a focus on meeting the needs of global customers, our portfolio of textile machinery includes 2 main solutions: the AI Visual Inspection & Automated Packing Solution, and the Automated Material Handling & Smart Storage Solutions. Through years of technological expertise, we have earned high acclaim from customers worldwide for the exceptional reliability and productivity of our products.