Since 2021, India has been plagued by the covid-19 epidemic. Many labor-intensive Indian factories have been forced to close. Many traders in the Sogla area of India have been affected by the epidemic. Local factories have been shut down. Many countries have textile industries in India. The factory was forced to shut down, and the global manufacturing industry was hit hard. Many European and American companies suffered heavy losses and had to transfer some textile factories back to China or other regions.

India itself is a major textile country. Due to the large-scale shutdown of India, a large number of manufacturing and textile orders have been forced to return to Europe, America, Southeast Asia and other countries, resulting in a sharp increase in orders for manufacturing and textile companies in these countries. This is a development for manufacturing and textile companies. Opportunities, but nowadays, affected by the epidemic, there is a shortage of labor, and it is very difficult for factories to recruit workers, and labor costs are increasing year by year. How to solve the labor problem in a short time has become a current problem.

The textile industry is a labor-intensive enterprise. Why does it employ such a huge number of workers? This is related to the textile production process. The textile process includes two parts: spinning process and weaving process. The spinning process mainly includes: cotton cleaning, carding, combing, drawing, roving, and spinning. The weaving process mainly includes: winding, warping, sizing, drawing-in, weaving and finishing.

In the process of spinning to weaving in the textile industry, every step is a major project. Most of the steps have not yet been fully automated, which often consumes a lot of manpower. Even if some factories have the conditions to use large-scale machinery and equipment, they also need manual assistance. Supervision.

Among them, warping, drawing-in, weaving, finishing and other steps are the most critical and labor-intensive projects. During the weaving process, the number of raw materials and products are very large, and a large number of cloth rolls are scattered on the ground and occupy a lot of space. Save the warehouse, the cloth rolls are often loaded on the weaving shafts and warp beams. Winding the cloth is also a tedious task. Although there is a winder at present, the switch of the winder and the supervision and verification during the winding process are all Specialized workers are required.

Even if the volume of the cloth roll is reduced, the weight is not reduced, and the finishing and handling of the cloth roll becomes a big problem. In the past, due to the heavy weight of the warp beams and weaving beams carrying cloth, two or more workers were often required to work together to move the truck, trolley transportation, and unload the cloth to the point. The whole process was time-consuming and labor-intensive. It can handle more than a dozen warp beams, and the speed is slow, the efficiency is low, and the error rate is high. Sometimes, in order to match the manual bearing capacity, the weight of the cloth roll has to be reduced, and a large cloth roll is transported multiple times, which greatly affects the handling efficiency.(try suntech Loom)

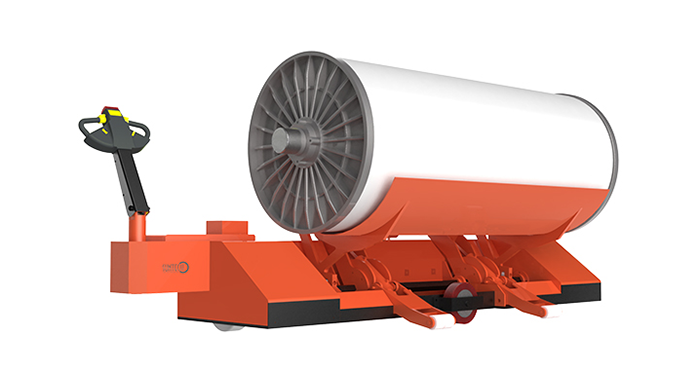

The Suntech electric axle car is specially designed for the loading and unloading and handling of cloth rolls, weaving shafts and warp beams. The electric axle car is designed with precise mechanical design so that the mechanical parts can just unload the warp and weaving shafts from the loom and seamlessly connect. It is loaded on the axle car in a stable manner, and then arrives at the axle storehouse after being transported steadily. Then the warp beams and weaving axles are loaded into the axle storehouse through the process of mechanical lifting. , Adapt to various working environments, make up for the shortcomings of manual handling, can reduce the labor intensity of porters in the textile industry, improve work efficiency, greatly reduce labor costs, improve production results and product quality.

WARP BEAM HIGH LIFT TROLLEY can be suitable for the upper shaft work of various looms. The maximum load of the warp beam is 1800 kg. The warp beam and heald frame can be transported at the same time. The handling capacity is equivalent to the handling capacity of 3-5 workers. Several times of manual loading and unloading, electric lifting, automatic loading and unloading, and sensitive response, eliminating many manual links and saving a lot of labor costs.

Suntech WARP BEAM HIGH LIFT TROLLEY mainly has the following advantages:

1. Maintenance-free gel battery

2. Electronic power steering

3. The electric side shift function can finely adjust the position of the warp beam

4. Maintenance-free AC motor drive wheels

Suntech, as an old-brand machinery manufacturing company, started with textile and storage machinery and equipment. It has international leading core technology. In order to solve the current short-term problems of manufacturing and textile industry, it has developed and produced WARP BEAM HIGH with 50 years of technical precipitation and design experience. LIFT TROLLEY can intelligently transport a large number of cloth rolls, fabrics, weaving beams, and warp beams, with a small footprint, large capacity, fast handling speed, flexible movement, stable carrying, free loading and unloading, strong adaptability to the site, reducing manual operations, and improving work efficient. Especially during the epidemic, when workers cannot gather for work, WARP BEAM HIGH LIFT TROLLEY is urgently needed.