Motorized and hydraulic systems are crucial for transmitting power and ensuring precise control in various applications within textile machinery. These systems are essential components of motorized warp beam trolleys, hydraulic beam trucks, and other material handling equipment, promoting efficient power transmission and smooth operation.

Key Differences Between Motorized and Hydraulic Systems

Although motorized and hydraulic systems serve similar purposes, they differ significantly in several important areas:

Power Source:

Motorized Systems: These rely on electrical energy, using motors to convert it into mechanical energy.

Hydraulic Systems: These use hydraulic fluid, pressurized by pumps and cylinders, to generate mechanical energy.

Control:

Motorized Systems: Utilize electrical signals to control motor speed and direction.

Hydraulic Systems: Adjust the pressure and flow of hydraulic fluid to control cylinder or actuator movement.

Responsiveness:

Motorized Systems: Generally more responsive, quickly reacting to electrical signals.

Hydraulic Systems: Typically slower due to the time required for fluid flow and pressure changes.

Efficiency:

Motorized Systems: Highly efficient in energy conversion, minimizing losses during the transformation of electrical energy to mechanical energy.

Hydraulic Systems: Often experience energy losses due to friction, heat dissipation, and other factors.

Cost:

Motorized Systems: More cost-effective regarding installation and maintenance, requiring fewer components and having fewer wear parts.

Hydraulic Systems: Offer greater durability and longevity, making them a better long-term investment despite higher initial costs.

Understanding these differences helps in choosing the right system based on specific requirements and trade-offs in textile machinery applications.

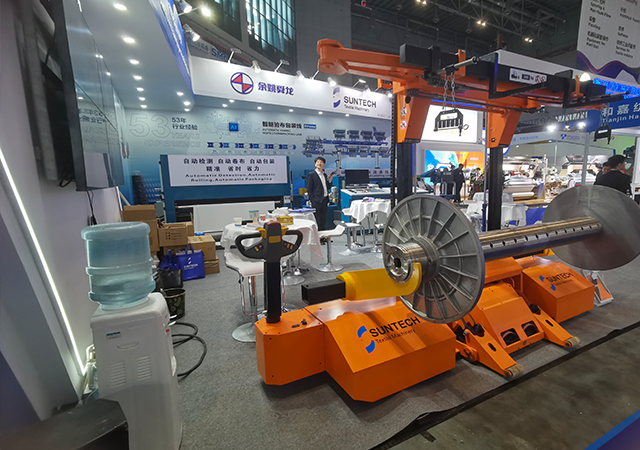

Types of SUNTECH Motorized Beam Trolleys

ST-MBT-02I

The ST-MBT-02I, part of SUNTECH's STelego series, is an advanced motorized beam trolley designed for bottom beam transportation, weaving loom insertion, and weighing weaving beams. It has a robust capacity of up to 1800kg, with an additional 300kg loading capacity for harnesses. Customizable in width (default: 170-340cm), it ensures compatibility with weaving machines without size modifications, offering exceptional versatility and flexibility compared to manual labor and traditional forklifts.

ST-MBT-01II

The ST-MBT-01II is a motorized beam lift trolley featuring a cradle-type design for effortless beam loading. It builds upon the standard electric warp beam lift trolley, offering enhanced convenience and efficiency. Suitable for looms 1.7m to 3.4m in width, it has a maximum loading capacity of 1800kg and a compact structure, making it ideal for operating in confined spaces. It excels in transporting and inserting bottom beams and facilitating batch picking and smooth transportation.

Both the ST-MBT-02I and ST-MBT-01II showcase SUNTECH's commitment to innovative solutions in the textile industry, enhancing productivity and simplifying operations.

Conclusion

Motorized and hydraulic systems each have distinct advantages and limitations. Motorized systems are ideal for applications requiring rapid and precise control, while hydraulic systems are better suited for tasks needing substantial power and durability. Selecting between these options involves evaluating performance, cost, and reliability to meet specific application needs effectively.