In the dynamic world of textiles, precision and efficiency are paramount, especially in the realm of fabric cutting. SUNTECH fabric cutting machines are engineered to meet the high demands of today's textile industry, offering advanced solutions that ensure quality and reliability.

Selvedge Cutting Excellence with SUNTECH

A selvedge cutting machine is essential for accurately trimming the edges of fabric before it is wound up. SUNTECH's ultrasonic fabric cutting machine stands out in this category. Designed for precision, it uses manually-operated scissor blades mounted on a sturdy structure, guiding the cutting edges along the fabric to achieve seamless trims. This machine excels particularly in cutting polyester fabric edges without causing damage, making it an invaluable tool for maintaining fabric integrity even when cutting strips.

Cutting-Edge Technology for Diverse Needs

SUNTECH's extensive range of fabric cutting machines caters to various cutting requirements. Each model is equipped with features tailored to specific tasks, ensuring optimal performance across different fabric types.

ST-USCM: Ultrasonic Fabric Cutting Machine

Versatile Cutting Modes: The ST-USCM offers multiple cutting modes, including laser, heat, and ultrasonic. This versatility makes it suitable for cutting synthetic fibers such as polyester and viscose, allowing users to select the best method for their material.

Enhanced Precision: The ultrasonic mode is ideal for thin rolls, providing precise cuts and sealed edges. For larger rolls, heat or laser modes are recommended, as they handle the preheated fabric efficiently, reducing smoke and odors.

ST-MSCM: Mobile Fabric Sample Cutter

Safety and Precision: Featuring a two-handed opening mechanism and a millimeter guide, the ST-MSCM ensures accurate cuts while prioritizing operator safety.

Mobility and Convenience: Its portable design allows easy transportation, enabling users to position the cutter where needed, saving time and effort in moving large fabric quantities.

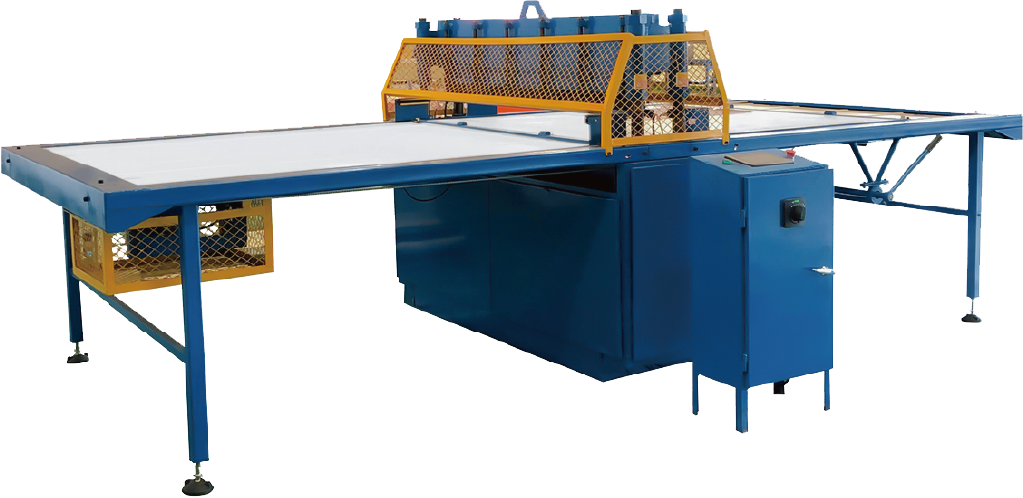

ST-ASCM: Advanced Fabric Cutting Machine

User-Friendly Interface: The touch screen interface of the ST-ASCM allows operators to input specific cutting parameters, ensuring customized and efficient operation.

Durable Blades: Crafted from Japanese alloy steel with a hardness range of HRC63-65, the blades can endure up to 200,000 cutting cycles, offering superior longevity and performance.

Safety Features: Equipped with hand protection light curtains, the ST-ASCM ensures a safe working environment by detecting objects or hands in the cutting path and stopping the machine immediately to prevent accidents.

Superior Quality and Reliability

SUNTECH fabric cutting machines are renowned for their high-quality components and robust construction. The cutting blades, made from imported Japanese alloy steel, boast exceptional hardness and durability, significantly outlasting standard cloth cutting machines. This quality ensures a long lifespan and consistent performance, enhancing overall cutting efficiency.

Additionally, SUNTECH offers a range of edge slitting cutters, including ultrasonic, cold, and heat cutters. These options cater to diverse customer preferences, providing a tailored cutting experience that meets various industry needs.

Conclusion

SUNTECH fabric cutting machines represent the pinnacle of innovation and precision in the textile industry. With advanced features, user-friendly interfaces, and a commitment to safety and quality, SUNTECH continues to lead the way in providing cutting solutions that elevate the standard of fabric processing. Whether for selvedge cutting, sample cutting, or large-scale fabric processing, SUNTECH machines deliver unmatched performance and reliability.