In 2021, China made 8.205 million tons of nonwovens, which was 6.6% less than in 2020. However, compared to 2019, the average growth rate over the past two years was 14.83 percent, which shows that the country is still growing steadily.

The most common ways to make nonwovens in China are spunbond and spunlace, which make up 85.8% of the total.

In China, the main places where nonwovens are used are for absorbent hygiene materials, medical and surgical materials, wipes, building and construction, packaging, filtration, and transportation.

And in China, 19.5 percent of all nonwovens are used to make absorbent hygiene products like diapers, tampons, and pads for adults who have to change their underwear often. Masks and protective gowns were much less in demand in 2021, but medical and surgical nonwovens still made up 10.6% of the market as a whole. Nonwovens are being used more and more in wipes, which make up 10.3% of the market. Packaging, filtration, geosynthetics, building and construction, and transportation made up 11.4%, 8.7%, 8.2%, 7.7%, and 6.1 %, respectively, of the market.

China's nonwovens industry will continue to use the new development philosophy of innovation, coordination, green, openness, and sharing. It will also stick to the growth direction of high-end, digital, and green, which will help the industry grow in a way that is both sustainable and high-quality.

Infection control efforts, consumer needs for convenience, and a general increase in new products in the category continue to drive demand for disposable wipes. In response, manufacturers of spunlaced nonwovens have been putting money into new lines in both developed and developing markets. These new lines not only increase the overall capacity of the technology around the world, but they also give companies that want to give their customers more environmentally friendly options more raw material options.

The number of face masks made in the EU, which are needed to fight the coronavirus pandemic, is expected to increase 20-fold by November of this year compared to the time before the crisis. This means that businesses in the EU will be able to make the same number of three-layer masks as 1.5 billion per month. These numbers show how quickly EDANA's members in the nonwovens sector responded to the COVID-19 pandemic and the EU and national governments' orders to increase the production of face masks to protect public health.

The new wave of investments in nonwovens around the world is a response to the need for gowns and drapes made of medically protective materials, which came up during the Covid-19 issue. A new study from Research Dive says that COVID-19 response operations are causing a 10 percent increase in these materials every year between now and 2026. This rise will be caused by both current demand and plans by the government to keep these substances on hand in case of a health crisis in the future.

Within the next several months, e-commerce will replace traditional methods of selling as the major way of choice for all businesses in the textile industry. The dependence that people place on their sense of touch has decreased throughout time. Additionally, an increasing number of textile businesses will use social media influencers in an effort to encourage customers to purchase their goods.

It is possible that, in the future, there will be an ever-increasing need for antimicrobial textile products and protective textiles. This is because of the growing relevance of both cleanliness and safety. It is more probable that a product will sell if it enhances the quality of life of the consumer as opposed to just being luxurious.

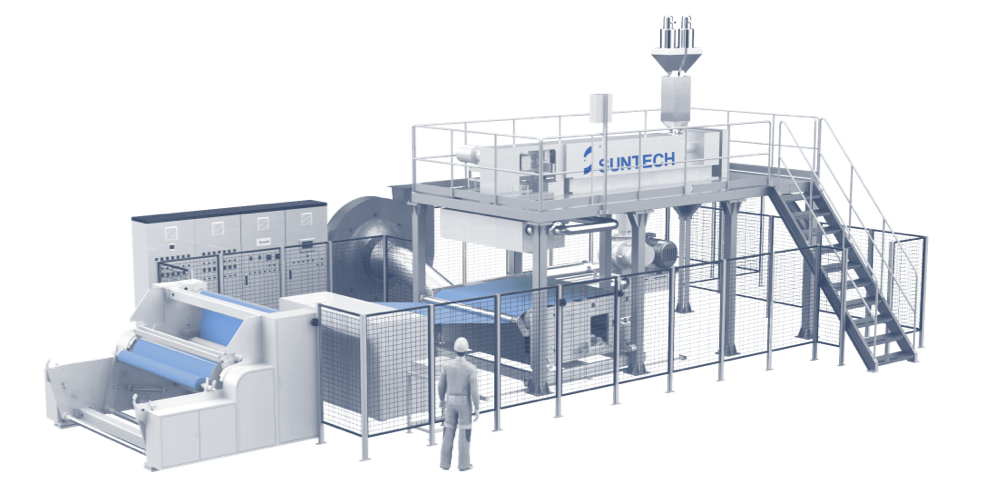

If you have interest in non woven machine, please contact us!