Meltblown non woven fabrics are widely used in the production of face masks, air filters, and other medical and industrial applications. One of the most pressing challenges facing humanity in the 21st century is the protection of our environment. While rubber, plastic, and synthetic fibers are integral to human life, their disposal poses a significant problem due to their inability to decompose naturally, leading to widespread pollution. In response, efforts have been made since the 1960s to research and develop biodegradable polymers and related products, with the goal of mitigating the negative impact of waste on the environment. Among these, polylactic acid (PLA) has emerged as one of the most promising biodegradable polymers, with its industrialization beginning in the late 1990s.

Meltblown Machine Market Trend

Meltblown machines are used to produce meltblown non woven fabrics, which are widely used in the production of face masks, air filters, and other medical and industrial applications. The COVID-19 pandemic had a significant impact on the market, as the demand for face masks increased rapidly worldwide. In 2020, the global meltblown non woven machine market size was estimated at USD 290 million, and it is expected to reach USD 370 million by 2027, growing at a CAGR of 3.5% from 2020 to 2027, according to a report by Grand View Research.

The Asia-Pacific region dominates the market, followed by North America and Europe. China is the largest producer of meltblown non woven machines, accounting for over 50% of the global production. The COVID-19 pandemic led to a surge in demand for meltblown non woven machines in China, and the government took several measures to increase the production capacity of these machines.

In addition to the COVID-19 pandemic, other factors driving the growth of the market include the increasing demand for face masks and other medical and industrial applications, technological advancements in the machines, and the development of new applications for meltblown non woven fabrics. However, the market is also facing some challenges, such as the high cost of machines, the complexity of the production process, and the environmental impact of the production process.

Overall, the meltblown non woven machine market is expected to continue growing in the coming years, driven by the increasing demand for face masks and other applications in the medical and industrial sectors. However, the market may also face some challenges, and companies will need to focus on innovation and sustainability to stay competitive.

Meltblown Nonwoven Fabric Market Trend

The COVID-19 pandemic had a significant impact on the market, as the demand for face masks increased rapidly worldwide. In 2020, the global meltblown non woven fabric market size was estimated at USD 7.59 billion, and it is expected to reach USD 10.20 billion by 2027, growing at a CAGR of 4.2% from 2020 to 2027, according to a report by Grand View Research.

The Asia-Pacific region dominates the market, followed by North America and Europe. China is the largest producer of meltblown non woven fabrics, accounting for over 40% of the global production. The COVID-19 pandemic led to a surge in demand for face masks in China, and the government took several measures to increase the production capacity of meltblown non woven fabrics.

In addition to the COVID-19 pandemic, other factors driving the growth of the market include the increasing demand for air and water filters, growing awareness about hygiene and health, and the development of new applications for meltblown non woven fabrics. However, the market is also facing some challenges, such as the fluctuating prices of raw materials, increasing competition, and the environmental impact of the production process.

Overall, the meltblown non woven fabric market is expected to continue growing in the coming years, driven by the increasing demand for face masks and other applications in the medical and industrial sectors. However, the market may also face some challenges, and companies will need to focus on innovation and sustainability to stay competitive.

SUNTECH Textile Machinery is a distinguished manufacturer of textile machinery with a rich legacy of automation and intelligent manufacturing technology for textile and warehousing equipment. SUNTECH's state-of-the-art core technologies have garnered global recognition.

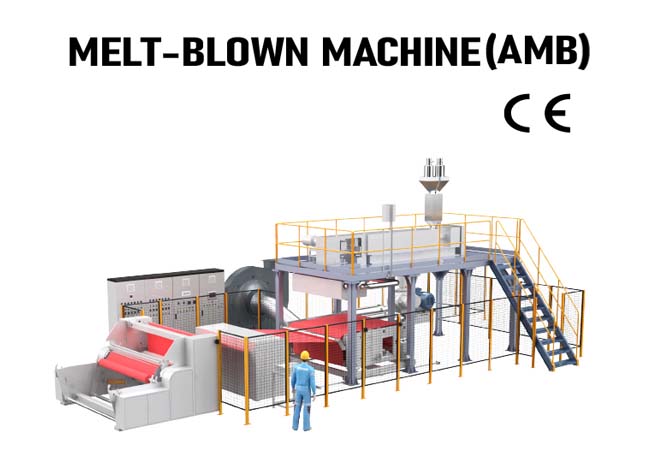

SUNTECH Textile Machinery has the range of products encompasses almost all fabric types, including but not limited to pinking machine, non-woven machine, beam truck, meltblown machine, fabric cutting machine, motorized beam trolley, beam storage, and fabric inspection machine. SUNTECH Textile Machinery continues to lead the textile industry with its innovative approach and extensive experience. We welcomes quotes and cooperation opportunities with open arms.