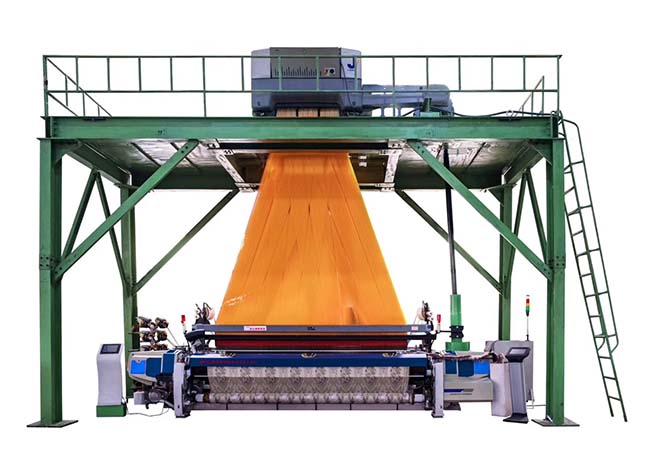

The jacquard loom machine, used to produce various jacquard fabrics, is one of the most significant textile machines. Like other machines, the jacquard loom machine also needs regular maintenance and repair to avoid various failures by using improperly or by running for too long. There will be a large number of product quality problems and even serious economic loss if we don’t repair and maintain it timely. Therefore, how to maintain the jacquard loom machine is extremely necessary.

Maintenance and Repair

The Jacquard loom is a complex and sensitive machine, requiring regular maintenance and repair to keep it running smoothly. The most common problems with Jacquard looms are broken or frayed yarns, loose heddles, and misaligned cards.

To prevent these problems, it is important to regularly inspect the loom for any damage or wear. Any damaged parts should be repaired or replaced immediately. The heddles and cards should be checked for alignment and tension regularly, and adjusted as needed.

In addition to regular maintenance, it is important to have the loom serviced by a qualified technician at least once a year. This will ensure that all the parts are in good condition and that the machine is running smoothly.

1. The rotor, axis and the mule spindle must be lubricated every day and the table surface must be daily wiped up to avoid falling objects from sticking to the mule spindle. Before starting the machine, it must be confirmed that there are no obstacles within the machine's motion range;

2. Refuel 2 to 3 times per shift, keep electrical appliances clean and compulsory maintenance must be carried out after 600-hour working of a new machine. The screw-purge is at the bottom of one side of the lower plate, drains off the engine oil that is on the lower plate and flushes it with diesel oil. Then add heat-resistant engine oil into the gear machine with the oil amount subjecting to the calibration line. The oil injection hole is on one side of the upper plate surface.

3. Check whether the gear oil in the base box of the jacquard loom machine is within the specified range or not per 30 days, which the gear oil must be in the middle of the 2 calibration of the oil measuring needle, adding oil when it is lower than the bottom line of the oil measuring needle. Don’t add too much to avoid oil spraying outside.

Run the machine at low speed for 5 minutes then speed it up slowly to clean up the broken wire guide rail on the table and rotating other parts in time to keep lubricating.

4. Annual maintenance of jacquard looms: check whether the oil in the lower plate is in the middle of the calibration line and check whether the oil in the turbine box is lower than the calibration line. Continuous rotating the parts to check if they are loose, then wash the spindle with gasoline. It is forbidden to use high-strength thinners, such as rosin and acetone. Replace the wear parts and add oil properly.

5. Clean the loom regularly. Dust and debris can build up on the moving parts and cause them to malfunction.

6. Check the tension of the warp threads regularly. The threads should be tight enough that they don't sag, but not so tight that they break.

7. Inspect the cards regularly for wear and tear. If any of the cards are damaged, they will need to be replaced.

Conclusion

The Jacquard loom is a critical part of the textile industry, and its maintenance is essential to keeping it running smoothly. By above these tips, you can keep your Jacquard loom in top condition and avoid any costly repairs. Do you have any other tips for maintaining a Jacquard loom?