Beam stacker, occasionally called beam carousel, is an important part of any beam storage system. It allows the efficient stacking of beams in a way that maximizes space and minimizes damage. Beam carousel must be carefully designed to ensure that it can handle the weight and size of the beams being stored. It must also be able to withstand the elements, as it will frequently be exposed to the elements when in use. Beam carousel can be made from a variety of materials, but steel is commonly used due to its strength and durability. Aluminum is another popular choice, as it is lightweight and corrosion-resistant.

Types of Beam Carousels

1. Manual Beam Carousel

Manual beam carousels are the most basic type of beam carousel. They consist of a frame that supports the beams, and a series of clamps that secure the beams in place. The clamps can be adjusted to change the angle at which the beams are joined.

2. Hydraulic Beam Carousel

Hydraulic beam carousels are similar to manual beam carousels, but they use hydraulic cylinders instead of clamps to secure the beams in place. This allows for more precise alignment of the beams.

3. Laser Beam Carousel

Laser beam carousels are the most advanced type of beam carousel. They use laser technology to align and join the beams. This results in a highly strong bond between the beams, and allows for extremely precise alignment.

Advantages of Beam Carousel

There are numerous advantages of beam carousel which make it an attractive choice for those looking for an efficient way to store and transport their materials. Beam carousels can be used in a variety of settings, including warehouses, distribution centers, and manufacturing facilities.

They offer a number of benefits over traditional storage methods, such as:

1. Increased Efficiency

Beam carousels are designed to optimize space utilization, which can lead to increased efficiency in your warehouse or facility. By storing materials on beams instead of the floor, you can free up valuable floor space for other uses.

2. Improved Safety

Beam carousels can help improve safety in your facility by eliminating the need for employees to climb on top of stacked materials. This reduces the risk of injuries from falls or toppling stacks.

3. Greater Flexibility

Beam carousels offer greater flexibility than traditional storage methods. They can be reconfigured to accommodate changes in your inventory or production process. Additionally, beams can be added or removed from the system as needed, allowing you to customize the system to meet your specific needs.

4. Reduced Costs

Beam carousels can save you money by reducing material handling costs. They eliminate the need for forklifts or other lifting equipment, and can also reduce damage to stored materials since they are not subject to being dropped or mishandled.

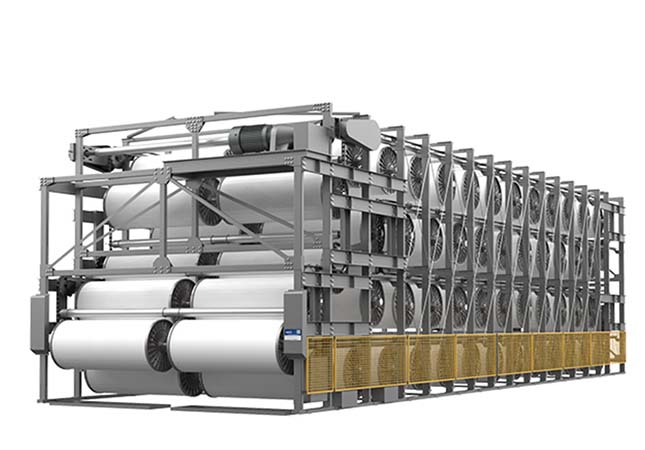

Although beam carousels can be particularly helpful in construction projects, there are also some disadvantages associated with them. One of the biggest disadvantages of beam carousels is that they can be really dangerous if not used appropriately, which means they can easily tip over and crush anyone or anything in their path. Another disadvantage is that they are very costly. The cost of renting or purchasing a beam carousel can be relatively high, which can make them out of reach for various construction enterprises. Finally, beam carousels require a lot of maintenance and repairs. However, in view of these 3 shortcomings, SUNTECH improved our beam carousel product-ST-BS, which is the computerized warp beam storage system that made by the latest chain synchronization automatic detection technology, which solves the disadvantage of danger and guarantees the operation safety and in good price! Also, SUNTECH provides you with local agents overseas (Bangladesh) for installation and after sales support. Contact us now!