Nowadays, everyone has stricter and stricter standards for the fabrics to be cut, and we hope that cutting fabrics will be easier; we hope that the cut fabrics can be neat and at the same time, we hope that the edges of the cut fabrics can have different shapes. And these requirements, SUNTECH's fabric cutting machine ST-MSCM can meet all and also can improve efficiency.

ST-MSCM enables to achieve efficient and easy fabric cutting. Do you know what features ST-MSCM has and how it can cut fabrics automatically?

Here are the features are following up:

1.Our blades are of good quality. For a good cloth roll cutting machine, the quality of the blade is very important, and the quality of the machine is closely related to the quality of the blade.In order to have a cutting blade with a longer service life, SUNTECH uses alloy steel with Hardness HRC 63-65 imported from Japan. And it can cut 200,000 times with good blade maintenance.

SUNTECH provides a 12-month warranty for the complete machine and a 24-month warranty for the blade. During our warranty period, SUNTECH will provide maintenance services and spare parts services, but the premise is that the damage to the machine is due to the quality of the machine itself. What’s more, our blades have Zig-zag or flat cutting blade.

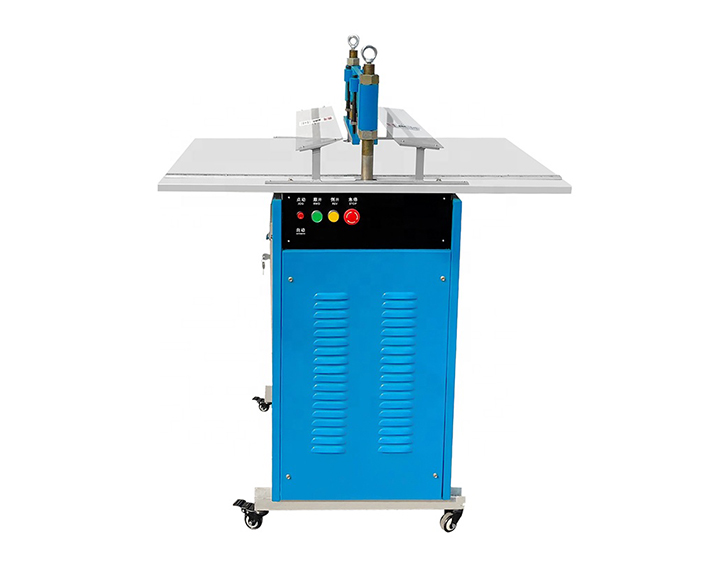

2. Scale on one side of cutting table. For swatch cutting, another important factor is the measurement of fabric length. When the worker has a definite cutting length, he can directly put the fabric on the cutting mat, and the measuring rulers on both sides of the cutting mat can help the operator to cut the fabric accurately. At the same time, the measuring ruler on both sides of the cutting mat also has a function to prevent the movement of the cutting mat.

3.Safety protection device. For companies and factories, protecting the safety of operators during operations is the number one priority. If workers are not protected during operations or without basic safeguards, it is very unsafe for both the factory and the workers. Our fabric swatch cutters have safety protection devices, namely hand protection sensors. The machine will automatically stop when any cargo or hand blocks the sensor's red light. This ensures the safety of workers when operating the machine to a certain extent, and prevents workers' hands from being cut during the operation.

4. Two pieces of cutting mat. In addition to the scale, our machines also have cutting mats. The cutting mat provides a protection for our desktop, and the weight of the cutting mat itself prevents it. Workers do not need to worry about the movement of the cutting pad during the operation, resulting in uneven cutting.

5. Control Panel. Compared to manual pattern cutting machines, automatic pattern cutting machines have several buttons to control the machine to start and stop. The operation and shutdown of the pattern cutting machine can be controlled simply and easily through the control panel. Compared with manual cutting machines, automatic fabric cutting machines are easier and less labor-intensive in the operation process

For the manual cutting machine ST-HSCM, the operation of SUNTECH's automatic fabric cutting machine will be easier, safer, time-saving and labor-saving.At the same time, ST-MSCM is still movable, and it is an automatic scroll wheel. So after reading this article, are you interested in SUNTECH's automatic pattern cutting machine? Want to cut fabric samples easily and safely? If you have this idea, just click our link!