In the textile industry, a warp tying machine plays a critical role in securing warp yarns during weaving. With several types of warp tying machines available in the market, each with its unique features and benefits, it is essential to understand the advantages of each. Therefore, this blog will explore the different types of warp tying machines and their benefits.

The Different Types of Warp Tying Machine

1. Tricot warp tying machine

The tricot warp tying machine, which has one or two needle bars, and the yarn is fed into the machine at a fixed angle, can produce complex patterns and designs, including lace-like effects. The fabric produced by the tricot machine has a relatively high density and a stable structure, making it suitable for a wide range of applications.

Advantages

l Versatile

Tricot machine can produce a wide range of fabrics, including delicate and intricate designs.

l High speed

Tricot machine can operate at high speeds, producing fabrics quickly and efficiently.

l High productivity

Tricot machine has a high production capacity, making them suitable for large-scale fabric production.

2. Raschel warp tying machine

The raschel machine has a single needle bar and is capable of producing fabrics with large holes or mesh-like structures. The machine is able to produce the fabric which is a relatively low density and flexible structure, making it suitable for a wide range of applications.

Advantages

l High versatility

Raschel machine can produce a wide range of fabrics, including fabrics with large holes or mesh-like structures.

l High productivity

Raschel machine has a high production capacity, making them suitable for large-scale fabric production.

l Low cost

Raschel machine is relatively simple in design, making them more affordable than other types of warp tying machine.

3. Simplex warp tying machine

Simplex machine, which has one or two needle bars and can produce fabrics with a relatively low density and a flexible structure, is used for producing a variety of fabrics, including sportswear, automotive textiles, and industrial fabrics. Which known for their versatility and can produce a wide range of fabrics with different patterns and designs.

Advantages

l Versatile

Simplex machine can produce a wide range of fabrics, including fabrics with different patterns and designs.

l High productivity

The simplex machine has a high production capacity, making them suitable for large-scale fabric production.

l Low cost

The simplex machine is relatively simple in design, making them more affordable than other types of warp tying machines.

4. Single-end tying machine

The single-end tying machine is one of the most common types of warp tying machine used in the textile industry. As the name suggests, this machine ties the yarns at the end of each warp beam, securing the yarns before they are fed into the weaving loom. The machine works by cutting the yarns to the desired length and tying a knot at the end, which is repeated for each yarn on the warp beam. The single-end tying machine is suitable for small and medium-sized weaving mills.

Advantages

l Low cost

The single-end tying machine is one of the most affordable types of warp tying machine, making it an excellent option for small and medium-sized weaving mills.

l Easy to operate

The machine is relatively easy to operate, and it requires minimal training.

l Consistent knotting: The machine ensures consistent knotting, ensuring that the warp yarns are secured properly.

5. Double-end tying machine

The double-end tying machine is another type of warp tying machine used in the textile industry. Unlike the single-end tying machine, the double-end tying machine ties the yarns at both ends of the warp beam. The machine works by cutting the yarns to the desired length and tying a knot at both ends simultaneously help to save time and reduce labor costs, making it an ideal option for large weaving mills.

Advantages

l High efficiency

The double-end tying machine can tie the yarns at both ends of the warp beam simultaneously, reducing the time required for knotting and increasing efficiency.

l Reduced labor costs

The machine requires less labor than the single-end tying machine, reducing labor costs for large weaving mills.

l Consistent knotting

The machine ensures consistent knotting, ensuring that the warp yarns are secured properly.

6. Automatic tying machine

The automatic tying machine, which is suitable for large weaving mills with high production volumes, is a high-tech warp tying machine that automates the knotting process entirely. The machine works by feeding the yarns into the machine, which then cuts the yarns to the desired length and ties a knot automatically.

Advantages

l High efficiency

The automatic tying machine is the most efficient type of warp tying machine, as it automates the knotting process entirely, reducing the time required for knotting and increasing efficiency.

l Reduced labor costs

The machine requires minimal labor, reducing labor costs for large weaving mills.

l Consistent knotting

The machine ensures consistent knotting, ensuring that the warp yarns are secured properly.

7. Semi-automatic tying machine

The semi-automatic tying machine is a hybrid between the automatic and manual tying machine, which works by feeding the yarns into the machine, then cutting the yarns to the desired length. The operator then ties a knot manually, and the machine cuts the yarns again to the desired length for the next knot. The semi-automatic tying machine is suitable for small to medium-sized weaving mills.

Advantages

l Higher efficiency than manual knotting

The semi-automatic tying machine is faster than manual knotting, reducing the time required for knotting and increasing efficiency.

l Reduced labor costs

The machine requires less labor than manual knotting, reducing labor costs for small to medium-sized weaving mills.

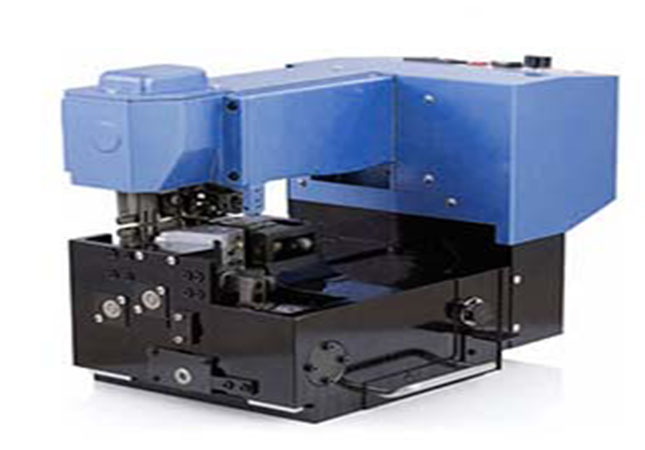

SUNTECH ST-WKM-II Warp Tying Machine ( Max. Speed 400 Knots/Min )

Warp tying machine is an automatic warp tying machine, which includes all the advantages above mentioned and the SUNTECH ST-WKM-II warp tying machine has unique advantages which help it stand out among the kinds of warp tying machines.

There are the features of the SUNTECH ST-WKM-II Warp tying machine

1. The machine can run at a speed of up to 400 rpm.

2. The actual splitting speed can be increased by 50%-100% compared to previous machines, depending on the yarn state.

3. The tissue benchmark can be split into a 1:1 ratio, which can also be changed to 2:2 by simply switching a switch.

4. Adjusting the warp tension is done through a single handle, making it easy to operate.

5. A special warp separation device is utilized for the corresponding tell operation.

6. The main part of the machine is actively driven by a cam, which provides stability and easy adjustability.

7. The yarn splitting needle can be easily exchanged with a simple one-step process.

Conclusion

In conclusion, selecting the right type of warp tying machine depends on various factors, including the specific weaving process, the type of yarns used, and the desired production volume. By understanding the different types of warp tying machines and their corresponding advantages, textile manufacturers can make informed decisions to optimize their production processes and stay ahead in a highly competitive market.

As a reputable textile machinery manufacturer with a rich history in automation and intelligent manufacturing technology of textile and warehousing equipment, SUNTECH Textile Machinery possesses cutting-edge core technologies that are recognized globally.

SUNTECH’s products cover the textile manufacturing and handling process of almost fabric types, in which pinking machine, non woven machine, beam truck, meltblown machine, fabric cutting machine, motorized beam trolley, beam storage, warp tying machine are the most popular machines and material handling equipment.

SUNTECH Textile Machinery leads the textile industry with our innovation and experience! Quotes and Cooperation are Highly Welcome!