Warehousing industry serves as the backbone of global supply chains, providing the essential infrastructure and operational expertise needed for efficient storage, handling, and distribution of goods. With technological advancements driving innovation, the industry continues to evolve, embracing automation, data analytic, and sustainability practices to meet the demands of a rapidly changing market. As global commerce grows, the warehousing industry will play an increasingly critical role in facilitating seamless supply chain operations and delivering goods to consumers around the world.

Safety and security play a crucial role in the warehousing industry, with warehouses implementing strict safety protocols and offering comprehensive training programs for operators of material handling equipment. Cutting-edge security systems are also employed to protect personnel, goods, and property, using access controls and surveillance technologies to prevent unauthorized entry and mitigate the risk of theft or damage.

As a result, material handling equipment serves as the lifeline of the warehousing industry by enabling efficient movement and storage of goods within facilities. This involves the utilization of various equipment such as forklifts, pallet jacks, conveyor systems, automated guided vehicles (AGVs), and robotic systems. These advanced technologies streamline operations, reduce labor costs, and enhance overall safety measures.

The field of Material Handling Equipment encompasses a wide array of machinery and tools specifically designed to handle diverse tasks within a warehouse environment. These equipment solutions are tailored to meet the unique needs of different industries, spanning from small-scale operations to large-scale distribution centers. The industry's characteristics are shaped by technological advancements, safety regulations, considerations for ergonomics, and the growing demand for automation and optimization.

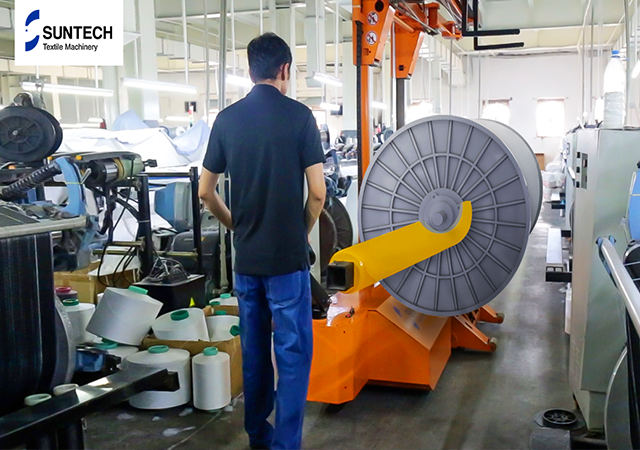

SUNTECH Upgraded Electric Warp Beam Lift Trolley ST-MBT-02I

1. Enhanced Battery Performance:

The upgraded SUNTECH Electric Warp Beam Lift Trolloey boast a lithium battery that significantly surpasses the capabilities of the older gel battery. With a threefold increase in service life, the new lithium battery eliminates the need for monthly charging and maintenance.

2. Advanced Electronic Steering System:

Unlike the previous fixed-speed electronic steering system, the upgraded model is equipped with a servo-assisted power steering system. This cutting-edge system ensures that the turning speed aligns perfectly with the handle rotation, resulting in faster and more precise maneuvering. The enhanced steering system delivers an improved truck handling experience overall.

3. Adjustable Beam Loading System:

Similar to its predecessor, the SUNTECH Electric Warp Beam Trucks feature a beam loading system that allows horizontal adjustment. With the ability to be adjusted by up to 100mm, this system provides flexibility and adaptability to suit various loading requirements.

4. Versatile Harness Mounting System:

The harness mounting system of the upgraded trucks incorporates advanced features such as electronic UP&DOWN and stretching capabilities. Additionally, it can be conveniently controlled remotely, offering greater ease of operation and efficiency.

5. High-Quality Electronic Components:

To ensure exceptional stability and extended service life, renowned American Curtis Drivers and Siemens PLC have been carefully selected as the electronic components for the SUNTECH Electric Warp Beam Trucks. These premium components enhance the reliability and durability of the equipment.

Conclusion

The advancements in logistics and warehousing, coupled with the introduction of cutting-edge material handling equipment like the upgraded SUNTECH Textile Machinery Electric Warp Beam Lift Trolley, underscore the dynamic growth and innovation within the industry. As logistics companies in China continue to show confidence and the warehousing industry embraces technological progress, the future looks bright for global supply chain efficiency and effectiveness. With ongoing developments in safety, automation, and sustainability, the industry is well-positioned to meet the increasing demands of global commerce.