Background

According to a study published by M Shahbandeh in Statista, the worldwide textile market is anticipated to increase from $1.5 trillion in 2020 to around $2.25 trillion in 2025, which suggests the demand for wear is increasing globally.

The huge potential in the textile industry calls for a more reliable and efficient method in the entire process. When it comes to fabric inspection, it helps understand quality in terms of color, density, weight, printing, measurement and other quality criteria before garment production. The fact that around 20% of defective garments are caused by flaws in the fabric, shows the importance to conduct pre-production quality checks on the fabrics. Exactly this may be accomplished with a fabric inspection, which can also guarantee the high quality of essential fabrics right from the start.

The Problems Faced in Traditional Fabric Inspection

Fabric makers and garment manufacturers both do quality control inspections on the fabrics they use. The process of evaluating the fabric sheet for the presence of flaws in the material and composing an inspection report is referred to as the fabric inspection. Following the examination of the fabric, the fabric will next be graded according to the overall quality level of the fabric.

Design, material selection, spinning, weaving, dying, and finishing are all processes that require a significant investment of time and resources in traditional textile industries.

For instance, while inspecting fabric, the fabric rolls are unrolled, the fabric is sent through a fabric inspection machine that has a light placed directly beneath the material, and the fabric checker does a visual examination of the material. During the process of examining textiles, a fabric checker will either place a sticker or a chalk mark on any flaws they find. This process might take several days or weeks, depending on the number of fabrics and quality materials that need to be identified. This procedure is laborious and often results in defects being passed into the final product.

In addition, the conventional manufacturing business relies heavily on human quality inspection methods, and the effectiveness of manual visual inspection is highly impacted by factors such as the body, weariness, and the surrounding environment. The unpredictability of the effectiveness of quality inspection will lead to losses for the companies. At the same time, the corporation struggles with both high staff expenses and recruiting management challenges. On the other hand, since there is no universally accepted format, it is difficult to retain and manage the data collected via human inspections.

However, if there are problems with the material, it may significantly slow down the whole process, from the pre-production stages through the phases of mass production, and of course, delivery to the consumer.

Why Is AI Application in Fabric Inspection That Important?

Defects in fabric reduce the value of textile products. Any flaws in the fabric are transferred into the finished product, which increases the likelihood that it will be rejected. Because of this, ensuring the fabric's quality is thoroughly examined before it is manufactured is of the utmost importance.

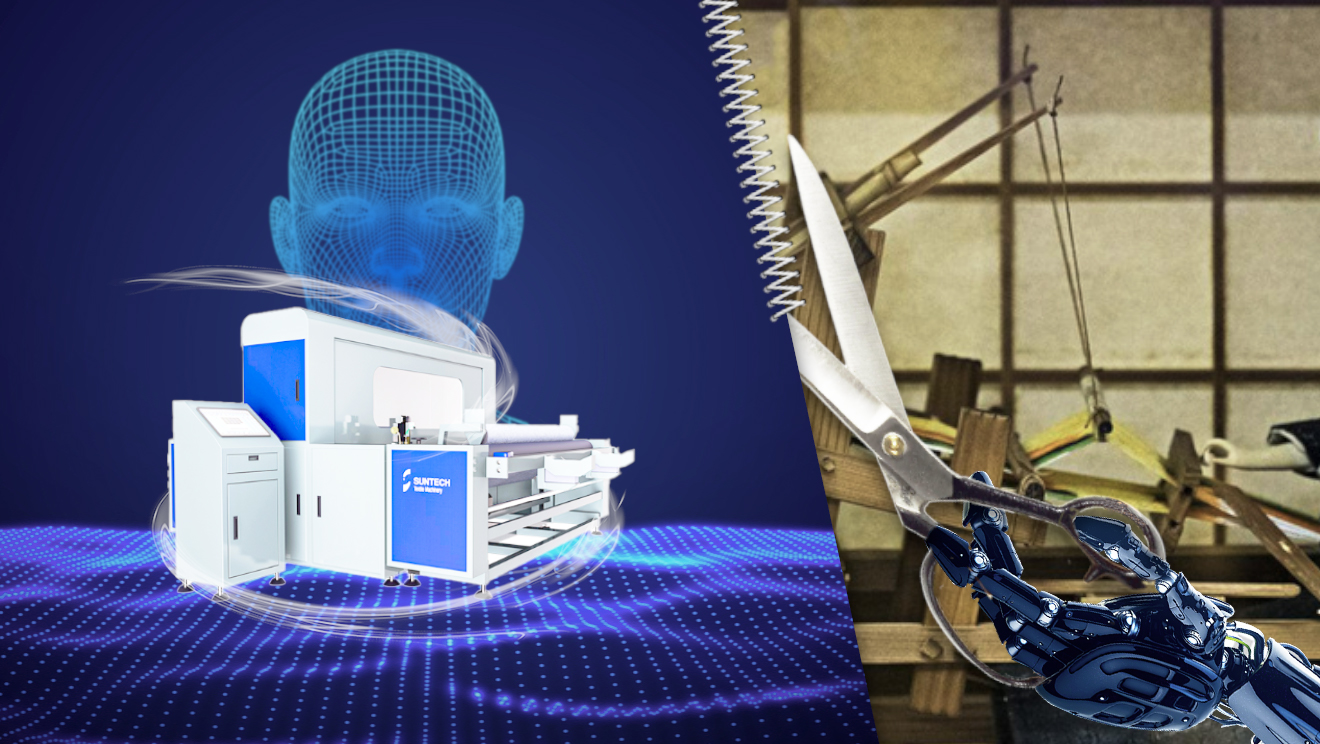

With the fast growth of industrial intelligence, the challenges that the conventional manufacturing sector faces, which are characterized by low levels of efficiency and high levels of expense, have become increasingly apparent.

But in the realm of industrial detection methods, the AI inspection approach has developed into a "breakthrough" with the benefits of being non-contact, high efficiency, cheap cost, and high levels of automation.

In this instance, the application of AI is capable of doing this work at a quicker pace, with a far greater level of accuracy, and without experiencing any weariness. With the assistance of neuro-fuzzy or another system, artificial intelligence may be used to anticipate the qualities of the fabric before it is manufactured. This can be accomplished by utilizing the yarn and the constructional data of the fabric.

In general, a fabric design may consist of a variety of elements, including weaving, knitting, braiding, finishing, printing, and other similar processes. By using vision-based inspection rather than visual examination, producers may be able to reduce the likelihood of human mistake and tiredness during the identification of innovations and flaws. In the textile business, artificial intelligence algorithms are used for fault detection throughout the fabric inspection process. The image of the fabric to be analyzed is retrieved from the equipment that does the image capture, and it is then stored in the appropriate standard image format, thus inspecting the fabric and recording the data immediately.

Current Market Situation

Artificial intelligence (AI) makes it possible for intelligent computer models to undertake formerly labor-intensive tasks, such as inspecting the patterns on fabrics or textiles.

SUNTECH Textile Machinery has created a ground-breaking and one-of-a-kind revolutionary fabric inspection technology. This method is designed to precisely identify even the tiniest of flaws in patterned textiles as they are being manufactured at high speeds.

Traditional methods for defect detection rely on human inspection which is ineffective, with detection rates under 65%, while the SUNTECH Inspection Machine with AI inspection system (SThinkor) machine can detect over 90% of defects with an accuracy of over 99.9%.

Manual inspection can take up to 20-30 minutes and has an average speed of 20-30cm/s, while the inspection speed of the AI fabric inspection machine may reach 40-60cm/s without halting the machine. SUNTECH Inspection Machine with an automatic camera inspection system can speed up to 60m/min with AI deep Learning for quality inspection.

Besides, the 24 Hours 100% Attention to ensure stable production can greatly save efficiency without worrying the tired of the workers.

Future Trends of the Textile Industry

The textile industry is one of the oldest and most important industries in the world. It is also an industry that is continuously developing and progressing. In recent years, one of the biggest changes to the textile industry has been the introduction of artificial intelligence (AI). In the future years, artificial intelligence will play a significant role in the modernizing of the textile sector by contributing to the improvement of company evolution and presenting sustainable fashion.

A wide variety of sectors have already begun to implement AI to pave the way for digitization and achieve more effective corporate growth. The epidemic that occurred in 2019 altered the processes of various sectors, and practically everything became digital as a result. The textile industry is not an exception because it is currently in the process of gradually embracing AI and automation to improve production, manufacturing processes, customer relations, and other aspects of their business.

The worldwide textile market size was evaluated at 961.5 billion USD in 2019, according to another analysis by Grand View Research. It is anticipated to demonstrate a CAGR of 4.3% from 2020 to 2027 due to the rising demand for apparel in developing nations such as China, India, Mexico, and Bangladesh.

This finding suggests that there is a growing demand for wear across the globe. The increased demand for products of a higher standard has prompted businesses in the textile sector to embrace automation and artificial intelligence (AI) to reduce the amount of money spent on labor and production while still meeting the demands of individual customers. With the help of AI technology, the future of the textile industry appears to be rather prosperous for all of the industry's participants.