As one of the important industries in the global economy, the textile industry involves the transportation and storage of a large amount of raw materials, semi-finished products and finished products during its production process. Moreover, the textile industry is characterized by large volume and variety, and has high requirements for the efficiency and safety of handling. In order to meet these needs, efficient material handling equipment is particularly important.

As a flexible and efficient material handling equipment, forklifts have been widely used in the textile industry. Forklifts can quickly and accurately carry textile raw materials and finished products of various specifications, effectively improving production efficiency. In addition, forklifts can also enter small spaces for operations, which improves the utilization rate of warehouses and improves handling efficiency.

As a professional textile machinery manufacturer, SUNTECH provides complete solutions for material transportation in the textile industry. In addition to providing ordinary forklifts, it also provides electric axle trucks, electric transport trucks and other forklifts designed specifically for the textile industry.

Application Of Forklifts In The Textile Industry

Raw Materials Storage: Eficient Handling

Large amounts of raw materials such as cotton and yarn are often transported in the form of bags, bundles or boxes. With its powerful lifting and handling capabilities, forklifts can quickly unload these bulky raw materials from transport vehicles. Equipped with different types of forks or clamps, forklifts can easily handle raw materials of various shapes and sizes. In addition, forklifts can accurately stack raw materials in the warehouse, making full use of warehouse space and improving storage efficiency.

Material Handling During Production

During the textile production process, semi-finished products and finished products need to be frequently transported between different production lines. Forklifts, as a "bridge" between production lines, undertake this important task. It can transport semi-finished products from one process to the next to ensure the smooth operation of the production line. At the same time, forklifts can also transport finished products from the production line to the temporary storage area or directly into the warehouse to improve production efficiency.

Finished Product Storage And Outbound

Finished textile products are often large in size and weight, and require forklifts to carry and stack them. Forklifts can classify finished cloth, clothing, etc. according to different varieties, specifications and batches, and neatly stack them in the warehouse. When leaving the warehouse, the forklift can quickly find the required goods according to the order requirements and transport them to the designated location to ensure timely delivery.

Forklift Type Selection

The textile industry has diverse needs for forklifts, and different processes have different performance requirements for forklifts.

Electric Forklifts:

Electric forklifts are pollution-free, low-noise, and suitable for indoor operations, especially for textile warehouses and production workshops. In the handling of textile finished products, semi-finished products, raw materials, etc., it has advantages in a quiet and clean working environment.

Internal Combustion Forklifts:

Internal combustion forklifts have strong endurance and are suitable for long-term and high-intensity operations. In places such as textile raw material yards and large warehouses that require long-term continuous operations.

Forward-Moving Forklifts:

The forks are retractable, suitable for narrow channel operations, and have high flexibility. Suitable for high-bay shelf storage and retrieval operations in textile warehouses.

Special Forklifts:

Specially customized for the textile industry, with strong targeting and high operating efficiency. Handling textile-specific materials such as paper tubes and cloth rolls.

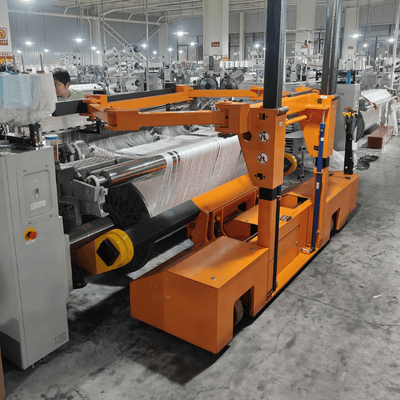

SUNTECH's Warp Beam Trucks

As a professional textile machinery manufacturer, SUNTECH has many years of R&D and manufacturing experience in the field of electric axle trucks. Our electric axle trucks are tailored for the textile industry, with improved transportation efficiency and simple operation as the core of the design.

Electric warp beam trucks are transforming material handling in the textile industry, offering a powerful combination of safety and efficiency. These robust machines are designed to effortlessly transport heavy warp beams, streamlining workflow and minimizing the risk of accidents.

The adjustable beam loading system and versatile harness mounting, with electronic UP&DOWN and stretching capabilities, provide unparalleled flexibility for diverse loading requirements.

Conclusion

The application of forklifts in the textile industry can not only improve production efficiency and reduce costs, but also improve the working environment and improve product quality. As an ideal choice for handling in the textile industry, SUNTECH Electric Warp Beam Trucks will bring higher efficiency and benefits to your business.