Automatic Packaging Machines are essential tools designed to efficiently package fabric rolls for transport and storage. These machines, widely used in the garment industry, wrap fabric around paper tubes and use appropriate packing materials, offering both manual and automatic operation options. Constructed primarily from durable materials like stainless steel, these machines can handle loads between 200 to 400kg, accommodating a variety of fabric rolls.

Operation of Automatic Packaging Machines

The core function of an Automatic Packaging Machine involves compressing fabric rolls to reduce their size, facilitating easier transportation and protection against moisture and wear. This compression makes handling more manageable and ensures the fabric's integrity. Post-compression, fabric rolls are securely sealed in plastic bags or containers for additional protection.

Working Principles of Automatic Fabric Roll Packing Machines

Automatic fabric roll packing machines are designed to package various types of fabric, including cotton, linen, and synthetics, efficiently. The process begins with rolling the fabric onto a spindle. A system of belts and pulleys then secures the roll in place. The machine automatically shapes the fabric into the desired form—such as roll-to-roll, plait-to-roll, or frame-to-roll—continuing until the fabric is fully packed.

SUNTECH Automatic Fabric Roll Packing Machine (ST-ARPM)

The SUNTECH Automatic Fabric Roll Packing Machine offers a fully automated solution for vacuum-sealed and efficient packing of fabric rolls. This machine significantly reduces labor requirements, handling up to 3360 rolls per shift. It features vacuum packing, labeling, intelligent sorting, and seamless integration with ERP systems, enhancing productivity and efficiency.

Features of ST-ARPM

The ST-ARPM boasts impressive features designed to boost efficiency in the textile industry. It can handle up to 7 rolls per minute, optimizing the packing process. Its intelligent classification capability eliminates manual sorting, connecting to ST-Thinkor for accurate fabric roll inspection and quality control before packing and labeling. This integration reduces defects and ensures precise packing with minimal human intervention, requiring only one operator.

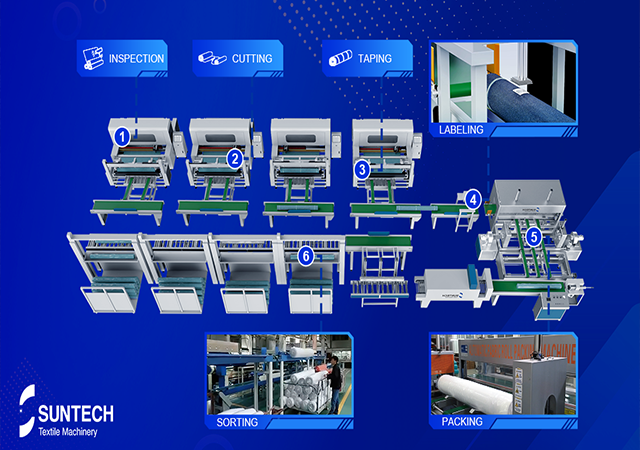

The Automated Fabric Roll Packing Line offers customizable options to accommodate various fabric roll sizes, shapes, and types, from delicate silk to robust industrial textiles. The system's AI-powered technologies include a comprehensive one-stop process for multiple tasks, starting with AI inspection. Computer vision algorithms detect defects in fabric rolls, ensuring only high-quality rolls are packed, thus maintaining manufacturer reputation and reducing customer complaints.

The machine also incorporates sampling and taping functions, autonomously extracting samples from each roll for quality control and securely applying tape to prevent unwinding or damage during transit or storage. Advanced mapping capabilities record and track each roll's location for efficient inventory management, while automated labeling affixes essential information for easy identification and tracking.

The packing process is executed flawlessly, with the machine adapting to various packing styles and materials, ensuring secure packaging of fabric rolls. The sorting function organizes rolls based on criteria like size, color, or destination, streamlining logistics and enhancing distribution efficiency.

Conclusion

The SUNTECH Textile Machinery Automated Fabric Roll Packing Line maximizes productivity with its intelligent features and remarkable capacity. It allows a single operator to oversee the entire process, thanks to its smart classification system. By integrating AI inspection, sampling, taping, mapping, labeling, packing, and sorting, SUNTECH Textile Machinery provides a fully customizable one-stop solution. This advanced technology ensures optimal efficiency, accuracy, and quality control in fabric roll packing for manufacturers.