SUNTECH was officially established as China’s first "fabric making-up machine" manufacturer at 1970s, to revitalize China’s textile industry. SUNTECH specialized in the field of textile machinery and became the leading textile machinery enterprise in China at that time by relying on technological innovation, professional R&D and the production of material handling equipment, weaving chine, fabric making-up machine and so on. With "automatic packaging machine" as our core product, we also derived the development of fabric inspection and packaging line, the main products include fabric inspection machine, fabric packaging machine, tube-sewing machine, etc, which has realized the transformation from manual production to mechanized production and automation of China textile industry and has created a solid foundation for today's auto textile machinery production.

SUNTECH has been engaged in fabric machinery for 30 years working and researching. Then the 21st century comes, which is a new era, the fabric and textile industry had unprecedented development during this time for meeting the needs of domestic and foreign fabric storage. Same as SUNTECH, we carried out industrial integration and upgrading and expanded the production line of "material handling equipment" and developed production lines such as cloth roll doffing/dosing trolley,warp beam lift trolley and motorized a-frame tractor.

SUNTECH transformed itself a technology-based manufacturing enterprise by specializing in field of technology machinery, injecting vitality into our company innovation for realizing the transformation from "mechanization" to"intelligent". Additionally, SUNTECH has made sure the future development by positioning with precise engineering and intelligent manufacturing" as the core. The fourth industrial revolution has come quietly after 21st century, it proves that the position of company development is correct. The, internet work and artificial intelligence have begun to rise at 21st century, which forces the traditional fabric industries and manufacturer hard to chase up the pace of the times. It turns out that the only way to catch up is to make enterprise intelligently developed. SUNTECH had a foresight for a long time so that began to develop the intelligent machinery industry when it was 2000. During the later 10 years, SUNTECH devoted a large amount of scientific research funds and time in intelligent machinery research and integrated automation, finally SUNTECH’s intelligent machine and equipment has gradually become the industry benchmark and become widely popular and widely use in the world. SUNTECH has more than 5000 customers and 17,000 machine installation cases around the world so far.

During past 20 years, SUNTECH set up a new factory for specializing in the production of intelligent "warehouse handling equipment", independently developed the intelligent storage equipment "beam stacker", and formed a patented technology.

At the beginning of 2020, the COVID-19 pandemic made us realize that the traditional fabrics and textile industries still rely on labor heavily, with a low production efficiency. Therefore, SUNTECH started to deepen the revolution of smart fabrics and material storage machinery and started to develop“full-time automated”and “no need manually operate” intelligent products -- the laser guided AGV, and industrial robots and intelligent three-dimensional warehouse.

Robot application technology has achieved great success in the research and development of new products. These products have won the favor of many customers overseas before they are officially released and have been successfully launched currently.

Here are some of our most popular lines and products, you may also want to know them :

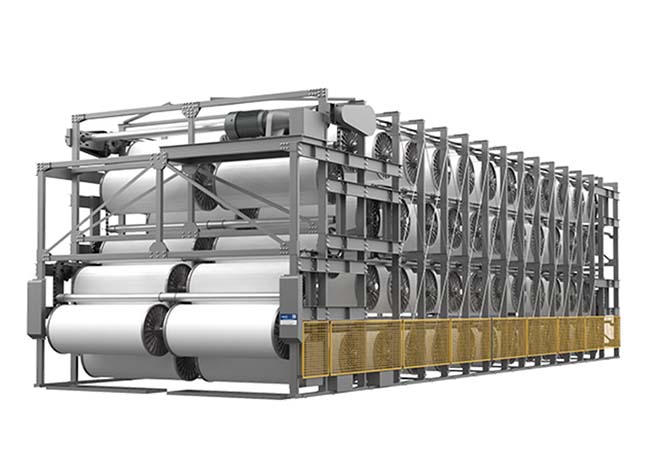

1. Automatic Fabric Inspection and Packing Line, combined with the state of art technology including camera inspection, automatic cutting, taping, labeling, packing, sorting and stacking.

2. Rapier Loom, Electric Trolleys (Trucks) with AC technology combined the intelligent Storage for Warp Beams, integration with the production or preparation system for a modern weaving mill.

3. Beam stackers for the needs of stocking warp beam,weaving beams,fabric rolls, control panel for simple operation.

SUNTECH’s global vision and ambition has not limited its success and growth in the domestic market. SUNTECH now has its agent network in America, Canada, Italy, Germany, Russia, Mexico, Argentina, Colombia, Peru, Ecuador, Guatemala, Indonesia, Vietnam,Thailand, Philippines, India, Pakistan, Bangladesh, Sri Lanka, Uzbekistan , Iran, Egypt, South Africa, Syria, Mauritius, etc. Over 120 countries!