The retail industry has seen a remarkable transformation with the rise of e-commerce, particularly in the area of warehouse handling equipment. Automation, robotics, and advanced technologies have revolutionized warehouses, making them more efficient and capable of handling larger quantities of goods. This shift is also impacting the labor-intensive textile industry, which faces challenges due to a shortage of skilled workers and high labor demands. To address these issues, textile manufacturers are increasingly focusing on improving production efficiency and reducing labor costs.

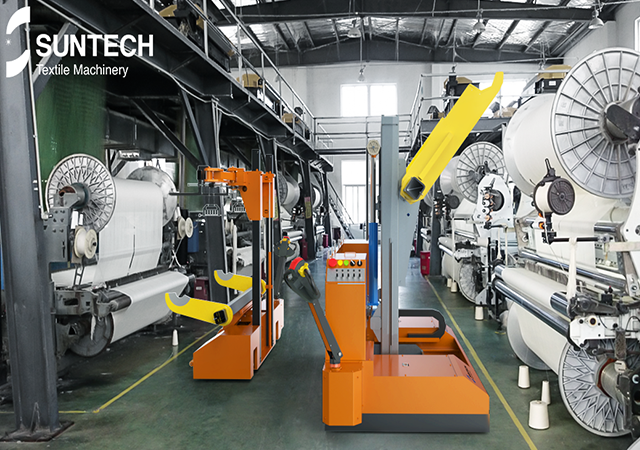

Efficient and safe textile material handling equipment, like the electric warp beam truck, has become essential in the textile industry. SUNTECH Textile Machinery is at the forefront of this transformation, committed to advancing efficient textile production through automation and intelligent design. Their SUNTECH Motorized Beam Trolleys are renowned for their quality and localized support, offering key features that meet industry needs. With continuous technological advancements, SUNTECH is driving innovation and providing significant advantages for their STelego series of products. The company's goal is to become a trusted, long-term partner in the textile industry.

In 2023, SUNTECH has implemented technological reforms and updates for the STelego series, resulting in a more efficient, safer, and convenient textile shaft handling process. These advancements have led to a 40% reduction in labor costs and a 60% reduction in time costs for textile production.

Upgraded Features of the 2023 SUNTECH Motorized Beam Trolley (ST-MBT-02I):

Enhanced Battery Performance:

The new high-performance lithium battery offers a threefold increase in service life compared to older gel batteries, eliminating the need for monthly charging and maintenance.

Advanced Electronic Steering System:

The upgraded model features a servo-assisted power steering system, ensuring seamless alignment between turning speed and handle rotation for faster and more precise maneuvering.

Adjustable Beam Loading System:

The improved system allows for horizontal adjustment of up to 100mm, offering greater flexibility to meet various loading requirements.

Versatile Harness Mounting System:

The new harness system includes electronic UP&DOWN and stretching capabilities, remotely controlled for easier and more efficient operation.

High-Quality Electronic Components:

Renowned American Curtis Drivers and Siemens PLC enhance the stability and service life of the equipment, ensuring consistent performance.

These upgrades make the 2023 SUNTECH Motorized Beam Trolley more efficient, reliable, and productive in textile shaft handling.

Enhancements in the Upgraded ST-MBT-05:

Extended Battery Life:

Featuring two sets of eight gel batteries, the upgraded model doubles the battery life, reducing the frequency of recharging and enhancing productivity.

Advanced Electronic Steering System:

The servo-assisted power steering system improves maneuverability by synchronizing turning speed with handle rotation for faster and more accurate handling.

Enhanced Beam Loading System:

The system now includes vertical adjustment capability of 600mm, with a uniform loading speed for improved stability and precision.

Military-Grade Oil Cylinders with Explosion-Proof Valves:

These enhancements ensure stability and safety during operation, reducing the risk of oil cylinder failures.

Premium Electronic Components:

Incorporating American Curtis Drivers and Siemens PLC, these components ensure long-term reliability and performance.

The upgraded ST-MBT-05 showcases significant advancements, resulting in improved productivity, precise handling, enhanced stability, and long-term reliability for various applications. Both the ST-MBT-02I and ST-MBT-05 models have obtained CE Certificates, confirming their compliance with rigorous safety and quality standards.

Conclusion

Motorized Beam Trolleys have revolutionized warehouse handling in the textile manufacturing industry, offering improved safety, productivity, eco-friendliness, and cost savings. As the industry evolves, manufacturers must embrace innovative solutions like these trolleys to stay competitive. By investing in advanced handling equipment, textile manufacturers can optimize operations and pave the way for a more efficient and sustainable future.

SUNTECH Textile Machinery is a leading expert in automation and intelligent manufacturing, providing advanced solutions for the global textile industry. With a mission to foster the development of the Chinese machinery industry, SUNTECH has established a vast network of agents in over 120 countries, including the United States, Canada, Italy, Germany, Russia, and many more.