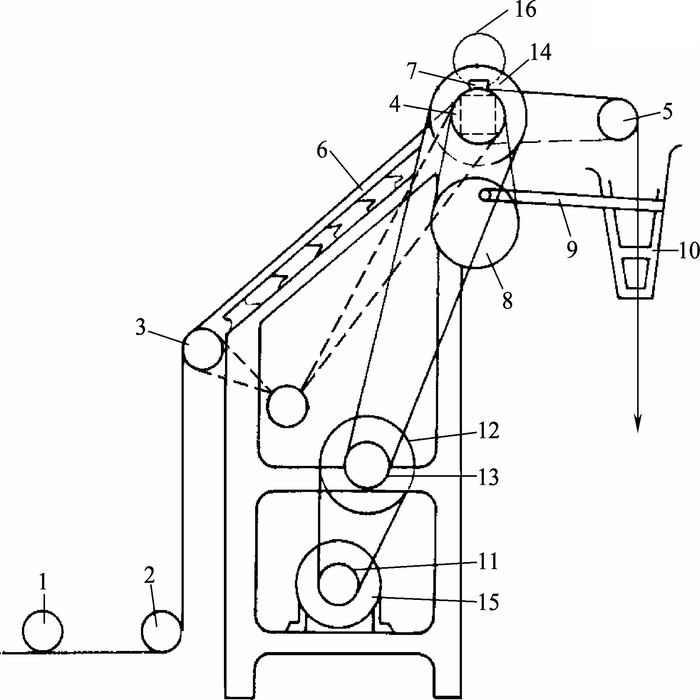

The fabric inspection machine is a device used for fabric inspection, generally composed of a frame, a fabric guide roller, a platform, an inspection table and other components. As shown in the figure, the grey fabric is drawn out from the fabric doffing car, passes through the guide rollers 1, 2 and 3 in succession. Then the fabric goes to the fabric inspection table 6. After being inspected automatically, the fabric then passes through the pulling roller 4 and the guide roller 5, and finally enters the swinging bucket 10. The swinging bucket reciprocates to make the fabric evenly folded. The movement of the fabric mainly depends on the pulling roller 4, and there is a pressing roller 16 above the pulling roller to increase the holding force of the fabric. In order to reverse a piece of fabric that has been already inspected once, the fabric inspection machine uses a set of clutch 7 to control the forward, reverse and stop rotation of the pulling roller 4, so as to achieve the purpose of advancing, retreating and stopping the fabric. The fabric inspection table is white frosted glass, equipped with upper and lower lights, suitable for inspection of various fabrics no matter it is natural or yarn-dyed, high-density or sparse, thick or thin.

Some fabric inspection machines also have the function of rolling fabric. They are used to inspect, reweave, and measure the fabric directly on the inspection table, and then directly pack the fabric into a roll for storage or send it to a printing and dyeing factory for processing. The machine is driven by a thyristor DC motor, and the inspection speed is steplessly regulated. The tension automatic control device is used to make the tension of fabric roller uniform. The fabric inspection machine achieves the uniformity of both sides of the winding edge through the automatic edge-aligning device with infrared photoelectric tracking, and ensures the accurate length by an automatic length-measuring device.

SUNTECH is one of the leading brand of fabric make-up manufacturers. Fabric Inspection Machines produced by Suntech are suitable for inspecting a wide range of fabrics, including woven fabric, knitted fabric and other kinds of fabric. Besides, it is suitable for different fabric forms from roll/plaited/A-frame to roll/plaited/A-frame. Suntech will offer the most suitable fabric inspection machines for customer and customize the Fabric Inspection Machines according to customers’ requirement.

Here are some most popular fabric inspection machines at SUNTECH

ST-WFIM ( Economic Type - for Woven & Denim Fabrics )

ST-WFIM Fabric Inspection Machine with optional data collection and analysis system (4-point system) can handle a wide range of rolled woven materials.This machine can be applied to operate from plait/loose fabrics to roll, or various other fabric inlet and outlet options.

ST-FIM( Universal Fabric Inspection; Ideal for Knitted Fabrics )

ST-SFIM Fabric Checking Machine with optional data collection and analysis system (4-point system) handles a wide range of fabrics. This machine can be supplied to operate from plait/loose fabrics to plait/loose fabrics, or various other fabric inlet and outlet options.

ST-TIM( Especially for Home Textiles )

ST-TIM Fabric Measuring Machine with optional data collection and analysis system (4-point system) to handle a wide range of fabrics, especially for home textiles. This machine can be supplied to operate from plait/loose fabrics to roll, or various other fabric inlet and outlet options.

.jpg)