In today's dynamic business landscape, the integration of automation has become paramount for driving efficiency and productivity across various industries. One such example is the utilization of automated fabric roll packing lines, which offer a plethora of advantages for businesses seeking to streamline their operations. Let's delve into the transformative features and cutting-edge technology that characterize these automated packaging machines.

Streamlined Operational Mechanism

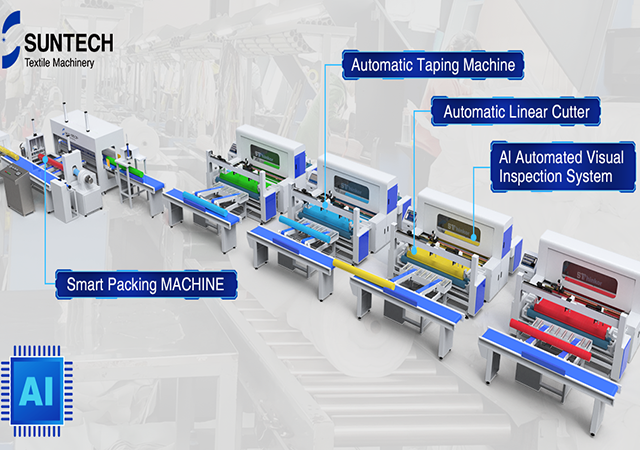

Automated fabric roll packing lines are ingeniously engineered production systems designed to expedite the packaging process with precision and consistency. These advanced systems encompass multiple stations, each meticulously configured to execute specific tasks within the packing workflow.

The initial station serves as the point of entry for fabric rolls into the line, seamlessly transitioning to precise positioning and cutting at the subsequent station. Once tailored to size, the fabric rolls proceed to the wrapping and packing station, where they are expertly encased into containers. Finally, the containers are securely sealed and conveyed to the shipping area, ensuring swift and seamless logistics.

Key Considerations for Efficient Packing

Efficient packing hinges upon several crucial factors that warrant meticulous attention. It is imperative to ensure the cleanliness of fabric rolls, eliminating any debris that might compromise the integrity of the packaging. Additionally, meticulous fastening of roll ends and accurate measurement of dimensions are essential prerequisites for a seamless packing process.

When opting for packaging methods, businesses must assess the suitability of utilizing boxes or alternative wrapping techniques. In the case of box packaging, precise positioning of the fabric roll within the container, coupled with appropriate filler materials, ensures optimal protection during transit. Alternatively, comprehensive wrapping with packing material and secure sealing facilitate robust packaging solutions tailored to diverse requirements.

Exploring Fabric Tensioning Devices

Fabric tensioning devices play a pivotal role in achieving optimal packaging outcomes, catering to diverse needs and preferences within the industry. Let's explore some prominent options:

Pneumatic Tensioners: Leveraging air pressure, pneumatic tensioners offer precise control over fabric tensioning, facilitating user-friendly operation and consistent results.

Electronic Tensioners: Equipped with electronic sensors, these tensioners deliver unparalleled accuracy and repeatability, making them ideal for demanding applications that necessitate exacting standards.

Mechanical Tensioners: Operating on mechanical mechanisms, these tensioners provide a cost-effective solution, albeit requiring proficient handling to optimize performance effectively.

Diverse Types of Fabric Roll Packing Lines

The market offers a myriad of fabric roll packing line variants, each tailored to specific business requirements and operational preferences. Here are notable types worth considering:

Fully Automatic Lines: Exemplifying unparalleled efficiency and convenience, fully automatic packaging machine, such as the SUNTECH ST-ARPM, are engineered to cater to high-volume production environments with speed and precision.

Semi-Automatic Lines: Striking a balance between affordability and operational efficiency, semi-automatic lines offer faster operation compared to manual alternatives, making them a viable choice for businesses seeking enhanced productivity without compromising cost-effectiveness.

Manual Lines: Providing unmatched flexibility and adaptability, manual fabric roll packing lines offer businesses the autonomy to tailor packaging solutions to diverse production needs, albeit at a slower pace and lower initial investment.

Navigating Challenges and Maximizing Benefits

While automatic packaging machine hold immense potential for revolutionizing production workflows, it is imperative to address potential challenges associated with improper usage and maintenance. Diligent storage practices and routine maintenance are paramount for mitigating risks of damage or operational disruptions, ensuring seamless integration of automation into the fabric packing process.

In conclusion, the adoption of automatic packaging machine heralds a paradigm shift in modern manufacturing, offering businesses unprecedented efficiency, productivity, and flexibility. By leveraging cutting-edge technology and adhering to best practices, organizations can unlock the full potential of automation to propel their operations to new heights of success.