Meltblown machine is used in the manufacturing of a wide range of products, including medical supplies, personal hygiene products, cleaning supplies, and so on. The machine is mainly used to cut large rolls of nonwoven fabric into smaller rolls or sheets of various widths, which are then used in the production process. There are main two types of meltblown machine popular in the market: automatic and common, this blog will explore the difference between these two machines, and provide more references for the customers.

Difference Between the Meltblown Machines

The following is a general introduction and the differences between these two types of machines in detail.

1. Meltblown Machine

An automatic meltblown machine is a state-of-the-art machine that is designed to provide high-speed, accurate, and reliable slitting of nonwoven fabrics. The machine is fully automated and uses advanced technology to ensure precise cutting and consistent results, which is an ideal machine for high-volume production environments where speed and accuracy are critical.

There are the main features of an automatic meltblown machine.

l High-speed cutting

Meltblown machine is capable of cutting at much higher speeds than manual or semi-automatic machines. It can process large rolls of fabric in a fraction of the time it would take a human operator.

l Precise cutting

The machine is equipped with advanced sensors and cutting tools that ensure precise cutting of the fabric. The cutting width can be adjusted to within a few microns, ensuring that the final product meets the required specifications.

l User-friendly interface

Meltblown machine is equipped with a user-friendly interface that makes it easy for operators to control and monitor the machine, allows operators to set cutting parameters, monitor the cutting process, and make adjustments as necessary.

l Automatic loading and unloading

The machine is designed to automatically load and unload fabric rolls, reducing the need for manual labor and increasing productivity.

l Quality control

Meltblown machine is equipped with quality control systems that monitor the cutting process and alert operators to any issues or defects. This ensures that the final product meets the required quality standards.

2. Common Meltblown Machine

A common meltblown machine is a more basic machine that is manually operated and is typically used in small-scale production environments where speed and precision are less critical. It is less expensive than automatic machine and is ideal for businesses that have limited budgets or low production volumes.

The main features of a common meltblown machine.

l Manual operation

Common meltblown machine is operated manually, which means that the operator needs to control the cutting process, which can be time-consuming and requires more labor than automatic machines.

l Limited speed

The machine is generally slower than an automatic machine and can only process a limited number of fabric rolls per hour.

l Basic controls

The common slitting machine has basic controls that are easy to use but offer limited flexibility. Operators can adjust the cutting width but have limited control over other cutting parameters.

l Manual loading and unloading

The machine requires manual loading and unloading of fabric rolls, which can be time-consuming and labor-intensive.

l Limited quality control

Common meltblown machine does not have advanced quality control systems and relies on the operator to monitor the cutting process and identify any defects.

3. Key Differences Between Automatic and Common Meltblown Machine

l Automation

The key difference between the two types of machines is automation. Automatic Meltblown machine is fully automated, while common meltblown machine requires manual operation.

l Speed

Automatic machine is much faster than common machines and can process a much larger number of fabric rolls per hour.

l Precision

The automatic machine offers much higher precision than common machines and can cut fabric to within a few microns.

l Controls

Automatic machine has more advanced controls and offers greater flexibility than common machine.

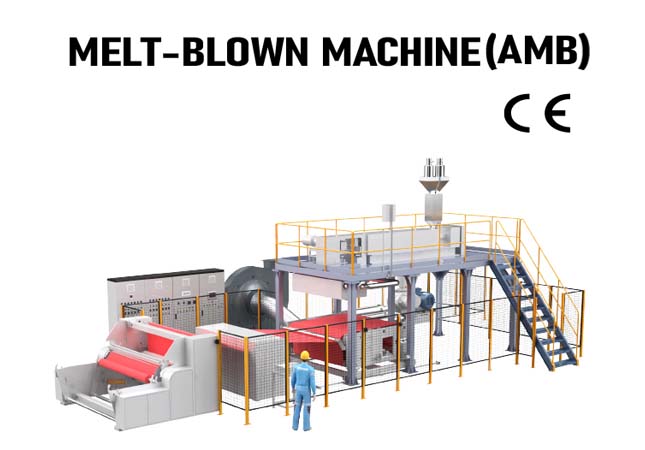

SUNTECH ST-AMB Meltblown Nonwoven Machine(AMB)

Features of SUNTECH ST-AMB meltblown nonwoven machine.

1. High-quality filter material production

The SUNTECH ST-AMB meltblown machine ensures top-quality filter material production that meets ultra-strict standards for filterability.

2. Consistent product quality and stability

In high-demanding industries such as medical protection, consistent product quality and stability are crucial for reliable performance.

3. Meeting the highest standards for filtering bacteria and viruses

Medical and surgical face masks require filter material that meets the highest standards for filtering bacteria and viruses.

4. Efficient production of sought-after filter material

By utilizing meltblown lines, suppliers can produce reliable and sought-after filter material quickly and efficiently.

5. Meeting rigorous requirements for filterability

With SUNTECH ST-AMB meltblown lines, you can confidently meet the rigorous requirements for filterability in the medical protection industry.

Conclusion

In conclusion, automatic meltblown machine and common meltblown machine are two different types of machines with distinct features and capabilities. While both machines serve the same purpose of cutting nonwoven fabric, the choice of machine depends on the specific production needs and budget of the business. And the SUNTECH ST-AMB nonwoven meltblown machine would be a perfect choice for all the manufacturers in the textile industry.

As a reputable textile machinery manufacturer with a rich history in automation and intelligent manufacturing technology of textile and warehousing equipment, SUNTECH Textile Machinery possesses cutting-edge core technologies that are recognized globally.

SUNTECH’s products cover the textile manufacturing and handling process of almost fabric types, in which pinking machine, non woven machine, beam truck, meltblown machine, fabric cutting machine, motorized beam trolley, beam storage, warp tying machine are the most popular machines and material handling equipment.

SUNTECH Textile Machinery leads the textile industry with our innovation and experience! Quotes and Cooperation are Highly Welcome!