In the textile industry, the storage and management of warp beams has always been a critical link. The traditional way of storing warp beams not only takes up space, but also easily causes damage to the warp beams, and even poses certain safety risks. In addition, with the improvement of production efficiency, the efficiency of manual management of warp beams gradually cannot meet the needs of modernization. The emergence of intelligent beam stacker provides enterprises with an efficient and secure new storage option.

The intelligent beam stacker combines automation and intelligent technology to not only improve storage efficiency but also significantly reduce labor costs by optimizing space utilization and simplifying operating procedures. This trend is in line with the concept of Industry 4.0 and is an inevitable choice for the future development of the textile industry.

Advantages of Beam Stacker

Efficient Storage and Space Optimization

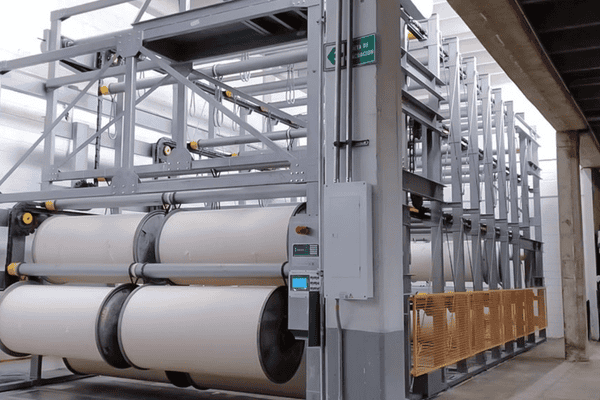

The intelligent beam stacker can achieve maximum storage capacity in a limited space through three-dimensional design and intelligent layout planning. At the same time, the system can automatically locate the warp beam position, avoiding the problem of chaotic warp beam stacking in traditional storage, and greatly improving storage and retrieval efficiency.

Safety and Stability

The intelligent beam stacker is equipped with safety fences and automatic loading and unloading systems to reduce the risks brought by manual operation. Both the safety of employees and the integrity of the warp beam can be fully guaranteed.

Automation and Intelligent Management

Thanks to the intelligent control system, the intelligent beam stacker can record the warp beam position in real time and generate storage reports. This not only facilitates daily management, but also keeps track of the storage status at any time and improves management efficiency.

Practical Application Cases

Intelligent beam stackers have been widely used. Taking a weaving factory in Bangladesh as an example, after the introduction of the intelligent shaft library, the storage space of the factory increased by 6 times, and at the same time solved the long-standing warp beam stacking problem. In addition, for large production lines, the intelligent beam stacker can achieve seamless connection of multiple production lines, greatly improving the overall production capacity.

The Uniqueness of SUNTECH's intelligent Beam Stacker

As an industry leader in the field of textile machinery, SUNTECH's beam stacker is famous for its leading technology and safety. SUNTECH's intelligent shaft library adopts a modular design and can be customized according to the needs of different factories. At the same time, its products are excellent in operation convenience and system stability, and are well received by customers. More importantly, SUNTECH provides comprehensive after-sales services, including equipment installation, commissioning and maintenance, so that customers have no worries.

Conclusion

Today, as the textile industry accelerates towards intelligence, beam stackers have become key equipment for improving production efficiency and management level. With its high efficiency, safety and intelligence, SUNTECH's intelligent beam stacker not only brings significant economic benefits to enterprises, but also helps them to remain invincible in the fierce market competition. In the future, choosing an intelligent beam stacker means choosing efficiency, safety and the future.