As competition intensifies in the global textile industry, companies increasingly demand production efficiency and cost control. In this context, introducing automated equipment and intelligent technology has become an important means to improve textile production efficiency and reduce labor intensity. As a key link in modern textile production, Beam Stacker is gradually becoming a core device to promote production process optimization and factory intelligent transformation.

Beam Stacker Introduction

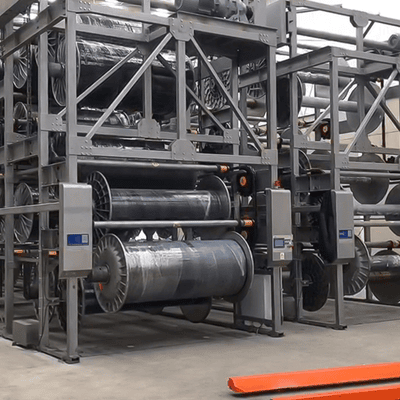

Beam Stacker (also called beam garage or beam warehouse) is an automated device used to store and manage beam items (such as warp beams, weft beams, etc.) in textile production. Its main function is to intelligently store, sort, retrieve, and distribute various beam items required in the fabric production process. Through automated management, beam stackers can effectively improve the material flow efficiency of the production line and optimize production scheduling.

Beam Stacker and Modernization of Textile Production

In the traditional textile production model, the shaft items required for fabric production are often stored and managed manually or semi-automatically. This method is not only inefficient, but also prone to problems such as item loss, damage, and difficulty in finding, which in turn affects production progress and quality. The introduction of beam stackers, through automated and intelligent management methods, makes item storage, finding, and distribution more efficient and accurate, thereby greatly improving the smoothness of the production process.

Advantages of Beam Stacker

(1) Improved Production Efficiency

The automated operation of the beam stacker can ensure that warp and weft beams on the production line are supplied in time, avoiding shortages or production stagnation caused by improper manual management. In addition, beam stackers can optimize the storage location of materials through systematic scheduling, making material search and retrieval faster, thereby greatly improving production efficiency.

(2) Reduced Labor Costs

In traditional textile production processes, the management of beams requires a lot of manual participation, which is labor-intensive and prone to errors. Through the automated operation of the beam stacker system, enterprises can significantly reduce labor input, reduce labor costs, and reduce the workload of operators.

(3) Improved ManagementEfficiency

Beam stackers can not only store items efficiently but also track inventory in real-time and provide accurate inventory data. This provides reliable data support for production planning, material procurement, and subsequent scheduling, avoiding material waste and misalignment problems, and further improving the accuracy of material management and production control capabilities.

(4) Optimized Space Utilization

Beam stacker adopts vertical storage and intelligent management to maximize the utilization of factory space. Compared with the traditional ground stacking method, beam stackers can store more items in a limited space, reduce the occupied space, and improve the storage utilization rate.

Beam Stacker Application Examples

Many leading textile companies have successfully introduced shaft library technology in their production processes. For example, after SUNTECH's large textile factory customer in Bangladesh applied the shaft library to the production line, the material storage and management efficiency was greatly improved, and the downtime of the production line was reduced by more than 20%. In addition, the integration of the beam stacker system with the production management system makes production scheduling more flexible and the production process smoother.

Beam Stacker Promotes Modernization of Textile Production

Beam stacker is not only an important part of modern textile production but also an important force in promoting the intelligent transformation of the industry. With the further development of technologies such as the Internet of Things and artificial intelligence, the future beam stacker will have more intelligent features, and can realize functions such as automatic monitoring, remote scheduling, and data analysis, thereby further improving production efficiency, reducing costs, and promoting the transformation of textile companies to "smart factories".

Conclusion

With the improvement of production automation and intelligence, beam stackers have become an indispensable part of the modernization of the textile industry. Through the application of beam stackers, textile factories can not only improve production efficiency and reduce labor costs but also optimize material management and promote the intelligence and refinement of the entire production process. For the current highly competitive textile industry, investing in a beam stacker system is undoubtedly a key step to improve productivity and achieve long-term development.