In ancient times, after human beings possessed advanced intelligence and thinking ability, they found that if they walked around "naked" like this again, it would be too detrimental to the dignity of the "overlord of the earth".

As a result, some wise primitive people began to collect some natural kudzu, hemp, mulberry silk and other materials, and made the simplest clothing to cover themselves.

Later, people learned to use the feathers of hunted birds to weave into rough clothes by hand, to replace the grass and fur that were used to cover the body.

In the middle and late period of ancient times, with the development of agriculture and animal husbandry, people gradually learned to grow hemp ropes, cultivate silk and other methods to weave clothes. Clothing made in these ways is not only light and warm, but also more beautiful.

Therefore, as one of the oldest industrial chains, textiles have a history of at least five thousand years. In ancient China, textiles were a very prosperous industry. From the Spring and Autumn Period and the Warring States Period, Chinese textiles and clothing have been arrogant and gorgeous in the world!

You must know that in Europe at that time, both the nobles and the commoners were still wearing those ancient skirts, each with naked and thick thighs, even the ancient Roman legions were no exception.

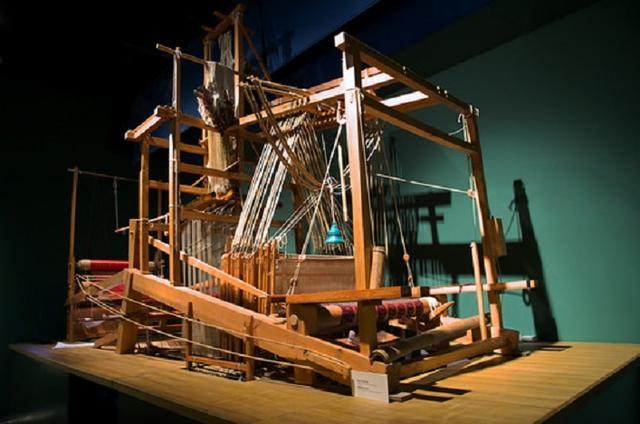

The key production tool for manufacturing textiles: the weaving machine, which has experienced at least four thousand years of evolution and development in China. The weaving machine not only greatly improves the efficiency of people's weaving, but also uses the cloth woven from it to make clothes, which is both gorgeous and durable.

In fact, as early as the Yellow Emperor era in China, there have been some sporadic records of weaving machines. The Yellow Emperor's wife, Leizu, and the second concubine, his mother, are also the originators of the legendary invention of the weaving machine and the spinning machine.

Since the Chinese first invented sericulture and silk making, the textile industry has always been one of the most important and long-lasting technological pillar industries in ancient Chinese society.

By the Spring and Autumn Period and the Warring States Period, a simple loom was widely used by the people for spinning. This is a spinning machine with two crossbars, a "knife" and a beating knife. When a woman is weaving, one end of the warp is tied to the wooden post, and the other end is tied to the waist of the weaver, so it is also called the waist machine.

This squat loom has no frame. One end of the winding shaft is tied around the waist, and the other end of the warp beam is continuously cycled to produce fabric. It can also be said to be the originator of the contemporary loom, until the Han Dynasty, it was the main special tool for women engaged in textile work at that time.

Later, in the production practice of people's weaving, many textile technologies were gradually innovated: a pedal-type twill loom was successfully created. The appearance of this weaving machine has also appeared many times on the stone portraits of the Han Dynasty.

When using this twill weaving machine, the weaver can sit and operate it, and both hands and feet are used in the production process, and the productivity is at least 10 times higher than the original weaving machine. It was the most advanced weaving machine in the world at that time.

Later, with the continuous development of loom technology, many models such as vertical looms, Dingqiao looms, Luo looms and so on appeared in ancient China. And the most advanced of them is the Hualou loom. According to historical records, this kind of loom with complex structure and high technical requirements appeared in the late Tang Dynasty, but its fame only reached its peak in the Song Dynasty.

As the most advanced weaving machine, it has a total of up to 1800 components to meet the weaving requirements of large, complex and colorful fabric patterns. For the first time, the Hualou loom separates the jacquard work from the weaving work, and is operated by a full-time person, who is the "flower puller".

When weaving, the weaver and the puller work together in coordination and cooperation: the puller sits high on the flower floor and pulls the bouquet with his hand to make the warp open. The weavers below do color matching and weft beating at the same time. Because it takes a lot of strength to lift the scriptures, the flower-pullers are generally men. And those who sit below while stepping on the pedals and throwing the shuttle colors are women.

Although the operator of the Hualou loom has increased by one person, the efficiency of weaving patterns and the level of fabrics have been greatly improved. The most gorgeous and intricate silk fabrics in ancient China were basically woven with this loom.

As far as the technological conditions at that time were concerned, the technical difficulty of the Hualou loom was comparable to that of a modern lithography machine, and its mechanical complexity and sophisticated technology ranked first in the world. As the highest achievement of ancient Chinese textile technology, until today, there is no modern loom that can completely replace this ancient Hualou loom.

While China has many advanced traditional textile machine technologies, it also spawned many "textile scientists" at that time, such as Huang Daopo who we learned in our textbooks. As one of the most famous cotton weavers at the end of the Song Dynasty and the beginning of the Yuan Dynasty, this woman who was born in poverty and lived in Yazhou in her early years has always been a Taoist temple. The technology of weaving "Yazhou quilt" with tools.

During the Yuanzhen period of the Yuan Dynasty (1295-1296), Huang Daopo returned to her hometown, and she began to reform the textile technology she had learned: she reduced the diameter of the spinning wheel by reducing the diameter of the three-spindle pedal spinning wheel used for hemp spinning. The extension force was changed into a three-spindle pedal spinning wheel that can be used for cotton yarn spinning, which greatly promoted the development of the cotton textile industry in Songjiang.

The industrial revolution has made a qualitative leap in loom technology, but the traditional Chinese loom "will last forever"!

Regarding the developed textile technology in ancient China, many people have ridiculed that: Since the Song Dynasty, the reason why the Central Plains has been invaded by nomads is actually because these "barbaric" people on horseback are very jealous of the textile technology of the Central Plains. , because the clothes on the people of the Central Plains are too gorgeous. However, these ridicules also prove a fact: the textile technology of the various dynasties in the Central Plains has been in a "dominant" position in the world for a long time.

Until the eighteenth century, the American worker Hargreaves invented the Anna textile machine. In 1785, the barber Edmund Cartwright invented the hydraulic loom, which suddenly increased the efficiency of weavers forty times. In the same year, Thales used the steam engine as a driving force for textile machinery, and it was quickly promoted, which further greatly improved the efficiency of weaving. These actually mean that the technological revolution of textile modernization in Europe and the United States is slightly inferior to the traditional Chinese textile technology.

In the development process of the modern textile industry, more forms of looms have gradually emerged: shuttleless looms, rapier looms, projectile looms, air-jet looms, water-jet looms, multiphase looms, Magnetic weft insertion looms, etc.

At this stage, the shuttleless weaving machine is the most used in the world. It uses more efficient automation technology and can weave fabrics of various compositions and colors faster.