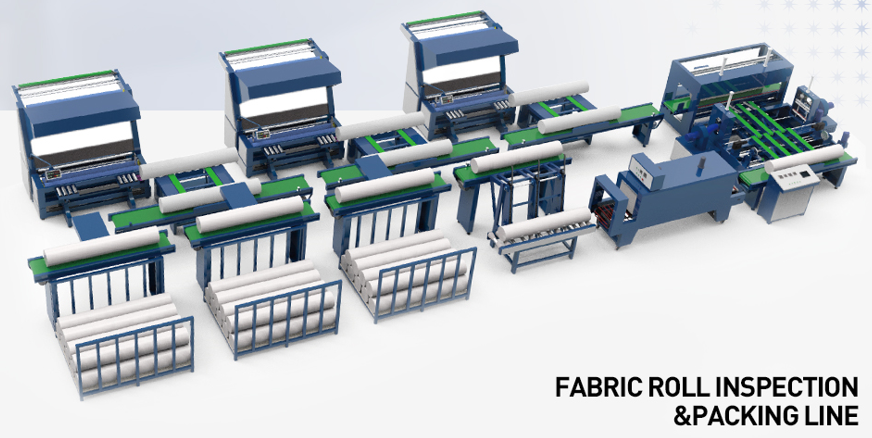

Compare with ordinary fabric roll wrapping machine, SUNTECH full automatic fabric roll packing line is more competitive. Automation means that after no one is directly involved, production management is carried out through machines, and automatic detection, information processing, and analysis and judgment are used to meet expected operations.

The use of industrial control automation technology is mainly to implement detection of instruments and computerized information technology through control, which can better reduce the corresponding detection methods, and through control and adjustment methods to meet its output and reduce energy consumption . Due to the large-scale application of automation technology in the textile industry, it can change the production energy efficiency of enterprises after technological innovation and maturity.

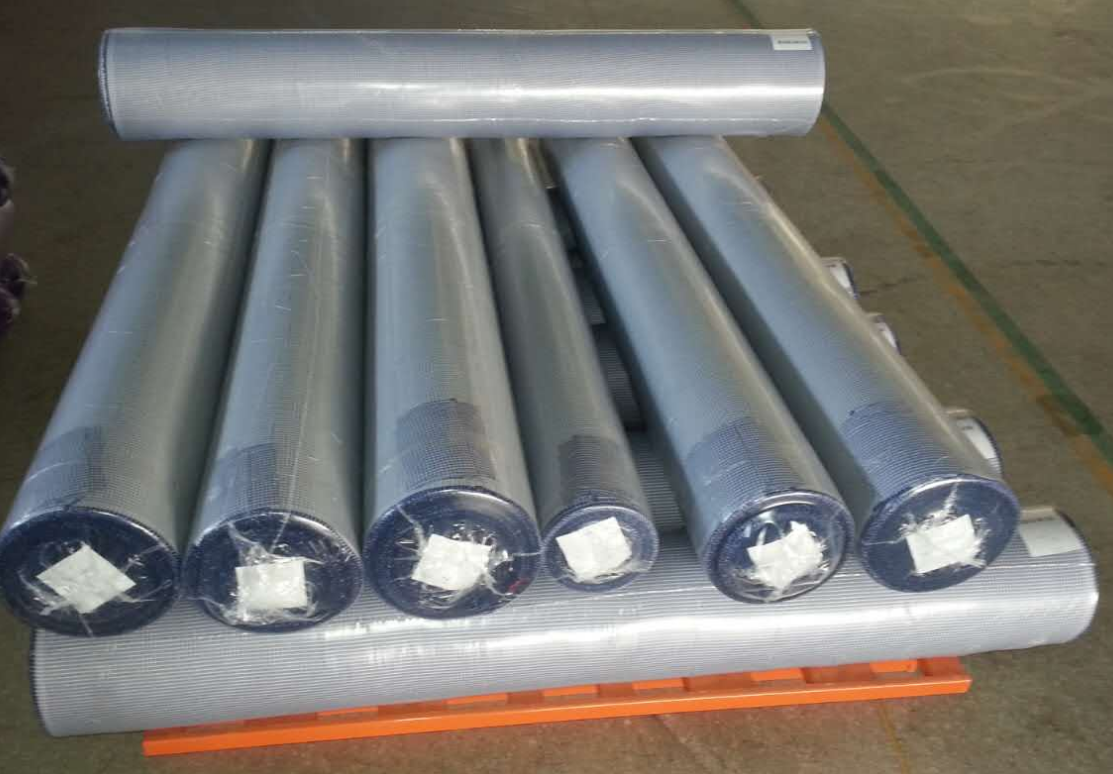

Suntech fabric roll wrapping machine supports max. 10 sets fabric inspection machines at the same time. The operator only needs to push the fabric roll on storage conveyor or fabric inlet conveyor, then the fabric roll will be transported to main packing machine to finish the packing, after packing, the fabric roll will be transported to heat chamber for better vacuum packing effect. The packing effect like below picture shows:

How to record the fabric defects during operation?

The fabric inspection machine is a set of necessary special equipment for testing cotton, wool, linen, silk, chemical fiber and other extra-large-format, double-width and single-width cloth before production in the garment industry. The operation method of the cloth inspection machine: provide the hardware environment for cloth inspection, continuously unfold the fabric in sections, and provide sufficient light source. The operator observes with eyesight, finds surface defects and color difference, and the cloth inspection machine automatically completes the length and package finishing work. The cloth inspection machine with good performance is equipped with an electronic defect inspection device, which is statistically analyzed by a computer to assist in the inspection operation and print out.

The basic structure of the fabric inspection machine includes 1) fabric unwinding, dragging and rewinding devices; 2) fabric inspection table, light source and lighting; 3) coding device; 4) fabric finishing device; 5) starting, reversing and braking device.

Each inspection machine requires one operator to check the fabric defects by eyes, if they find the fabric defects on fabrics, they can stop machine and record the fabric defects. More and more customers are focus on quality management, SUNTECH fabric faults record system meet their requirement. Compared with other Chinese fabric inspection machine manufacturers, Suntech has experienced technical teams, our gain provide customized solution, provide the best service to each customer.

We will install the software into the computer and connected the computer with the machine, after receiving our machine, the operator needs identify 24 defects onto the software in the computer and the computer will record some general information input like date, order, shift, operator's name. When the operator found defects when inspecting, manually stop the machine, select defects and give penalty from 1-4 serious degree on operation panel. The computer will record the type, the position and the serious degree of the detects. The printer prints the results.

We will provide the full complete system, including software system, industry computer, printer, in order to guide the customer to use our system, we prepared guidance video in our youtube.

What’s the fabric inspection machine price?

Different customers have different requirements, that’s why we need to ask the customer to know what’s the main function do they need? What’s their expected price?

It’s hard to compare the price without machine specifications, even the machines with same function, if the components are different, the customer can not find the difference on machine body. The main point of the fabric inspection machine is not the price, the customer should pay much attention on working performance.