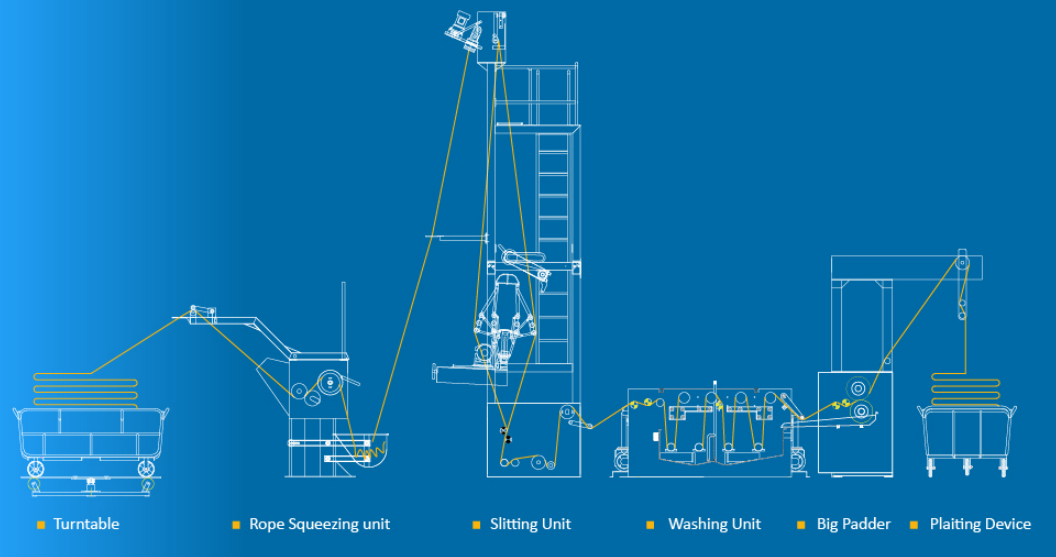

Tubular Fabric Slitting Machine with Rope Opener is used before stenter and open width compactor. The slitting machine can slit the tubular fabrics and then squeezing the water, washing the fabric,etc.

The whole process including turntable,rope squeezing unit,slitting unit,washing unit,big padder as well as plaiting device. How every part working and what’s their function?

Hydraulic Turntable

The Turntable is synchronize with the detwister. The structure driven by single motor for processing heaving trolley. As the wet tubular fabric is very heavy for processing,The turntable is controlled by fluid power, with strong rotating circular plate and underlying structure fixed on the machine, it is for fabric fabric carriage rotation in heavy duty condition. What’s more, it facilitate the operation of rope de-twisting after washing or dyeing. It can help the wet fabric turn around,which is easier for rope opener.

Squeezing Unit

The squeezing unit is a simple device which is used to remove some part of the water on the wet fabric,which can avoid the water splash during the following slitting process.

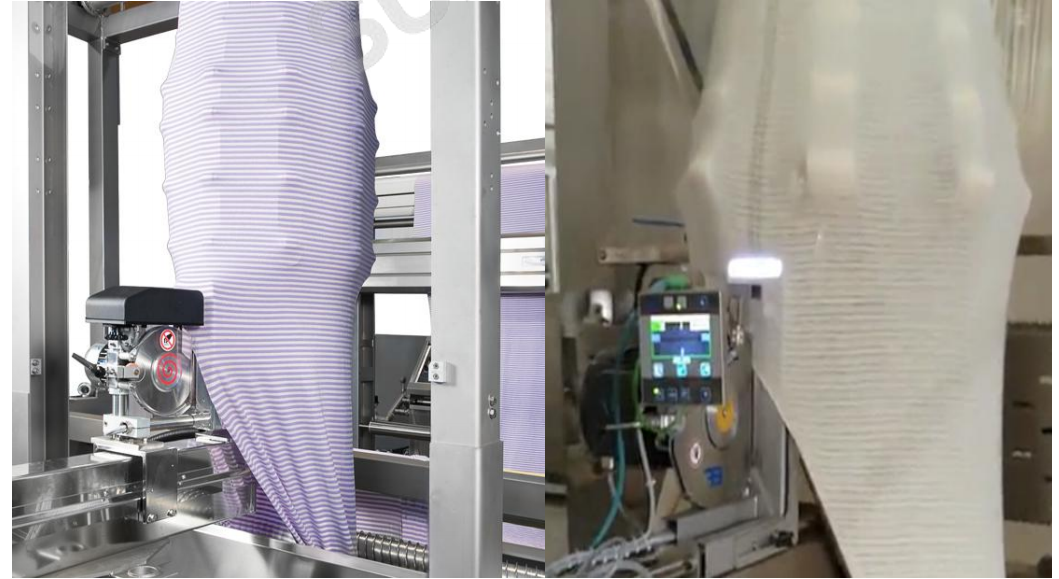

Slitting Unit

The slitting cutter would be brand E+L 2535. By means of a hand-wheel, the diameter of the round basket can be expanded from 320mm-800mm, so as to facilitate the spreading of fabric and prevent permanent weft distortions, as may be generated by the slitting process. Also the needle drop sensor can detect the needle drop on the fabric and adjust the basket to place the fabric in proper slitting position. Both slitting and rope opening function.

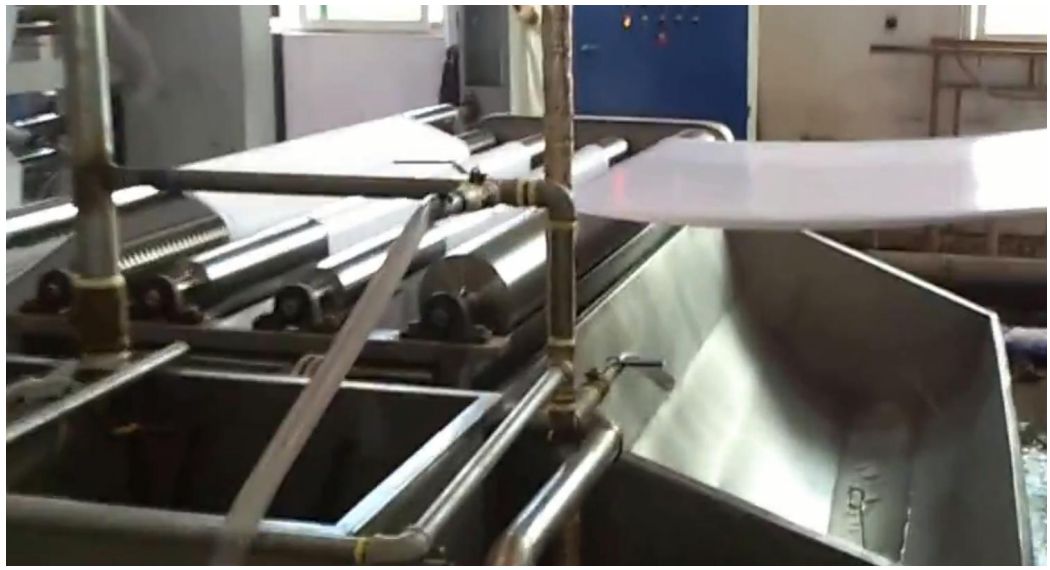

Washing Unit

This filter device is including water pump, spraying tube, and automatic filter box. All the material are stainless steel in 2cm thickness. The water pump is in 3kw, there are 5 pieces spraying tubes, and the automatic filter box(with brushing device),which can remove enzymatic residuals to reduce economic and environmental impact

Big Padder

Big Padder is used for Water Squeezing. After the fabric is slitted to open width,the wet fabric will pass through the big padder,which has two roller to press the wet fabric to remove more water

Plaiting device

Fabrics after squeezing liquid will exit with plaiting, it is drivin by active roller, driven by three phase motor.

Suntech is a world-wide acting enterprise with decades of tradition and experience. Over 50 years of innovation, Suntech develops, produces and distributes high quality Fabric Make-up Machines, Material Storage & Handling Equipments, based on Digitization, Automation and Intelligence. In addition, Suntech constructs since many years special machines for particular applications to meet with our customer’s individual requirements. In year 2018, Suntech becomes a member of Strength Group,which is located in Hangzhou city, Zhejiang.

SUNTECH can customize the functions of the machine according to the different needs of customers. The price of the automatic tubular fabric slitting machine is depending on different functional configurations, but it can meet the needs of customers to the greatest extent. Our customers in Pakistan, India, Bangladesh, Canada,USA,Europe, etc. they are very satisfied with our machines, most customers establish long time business relationship with us.

We use TOP brand main components to ensure the machine stability and long service time,such as Innovance inverter, Schneider button and connectors, Airtac filter and cylinders, German E+L slitter,Innovance PLC,etc. Our high-quality and low-cost products are deeply loved by our customers

By the way,SUNTECH has professional service team. We have after service department who is responsible customer’s after-sale questions,any of your questions will be replied within 24 hours,and we also have many oversea installation and service team,who can provide on site installation and local service. I believe we can do better!

There are fabric slitting machine for sale and other automatic fabric cutting machine at SUNTECH!