In the realm of international competition, the advancement of fiber materials, particularly advanced functional fibers, plays a critical role. These innovations are essential for the stability and security of industrial and supply chains, as well as for generating industrial value and future opportunities. Advanced functional fibers are central to modernizing the textile industry, holding immense strategic importance.

As we witness the emergence of a new industrial revolution, fiber innovation must adapt to these changing times and capitalize on new opportunities. The industry needs to explore new avenues through integration, adopt innovative paradigms driven by intelligence, and create value through sustainable practices. Here are three pivotal strategies for the development of advanced functional fibers:

Balancing Safety and Development: It is crucial to ensure the stability of industrial and supply chains while making strides in key raw materials, technologies, and equipment for new fiber materials.

Future-Oriented Development: The industry should focus on forward-thinking advancements, strengthening interdisciplinary and cross-domain basic research, and fostering original innovation.

Enhancing Quality and Efficiency: This involves upgrading both supply and demand, accelerating collaborative innovation among industry, academia, research, and application, and fostering a virtuous cycle powered by talent, innovation, market demand, and capital.

Progress and Future Directions in China's Fiber Materials

China's fiber materials industry has achieved significant advancements in terms of industrial scale, product quality, variety, functionality, and the greening and digitization of fiber production. As highlighted by Director Cao Xuejun, advanced functional fibers substantially improve the high-quality supply of textiles. The development of high-performance fibers broadens the market for textile applications, and the adoption of bio-based renewable and degradable fibers bolsters the green textile movement.

To transition from a position of trailing or keeping pace to leading globally, the industry must:

- Heighten the urgency of innovation.

- Strengthen the advantageous position of the textile industry chain.

- Explore new technological frontiers.

- Enhance standards, certification, and rules to improve the supply of low-carbon and green products.

- Chemical Fibers: Categories and Raw Materials

- Basic Categories of Chemical Fibers

Chemical fibers are synthesized through chemical methods and include both synthetic and semi-synthetic fibers:

Modified Fibers: These fibers are new variants developed from natural or chemical fibers, such as Lycra, spandex, and elastic fibers. They are known for their elasticity, comfort, and breathability, making them ideal for underwear, dancewear, and functional clothing.

Unmodified Fibers: This category includes polyester, nylon, and acrylic fibers, which are valued for their durability, abrasion resistance, and corrosion resistance, commonly used in clothing, socks, and household items.

Semi-synthetic Fibers: Produced by blending natural fibers with chemical fibers, examples include viscose fibers, metallic fibers, and electrospun yarn.

Raw Materials for Fiber Production

The raw materials for fiber production encompass fossil fuels like coal, petroleum, and natural gas, as well as natural materials such as wood and plant fibers. Petroleum is a primary raw material for synthetic fibers, while other fossil fuels and natural materials also play significant roles in the production process. Common materials used in the textile industry include cotton, flax, wool, silk, and polyester. Depending on production needs, textile companies select different raw materials based on product quality, market positioning, and cost considerations.

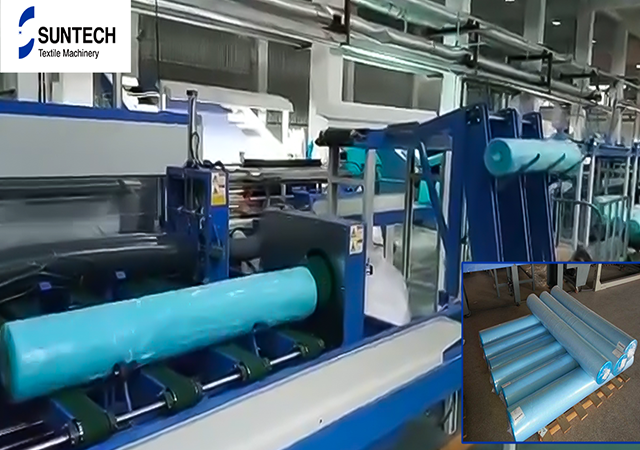

Leading Innovation in Textile Machinery: SUNTECH Textile Machinery

SUNTECH Textile Machinery offers a comprehensive range of products catering to various fabric types. Their portfolio includes weaving machines, beam trucks, fabric cutting machines, motorized beam trolleys, beam stacker, and fabric inspection machines. SUNTECH continues to lead the textile industry through innovative approaches and extensive experience. They welcome quotes and cooperation opportunities to further advance the textile industry.