The textile industry has undergone significant transformations, propelled by technological advancements in textile machinery. This article delves into the pivotal role of textile automation, exploring how it has revolutionized the industry by improving efficiency, ensuring product quality, and fostering sustainability.

Boosting Production Efficiency:

Textile machinery, particularly automated systems like spinning frames, looms, and knitting machines, has replaced manual labor, leading to a substantial increase in production efficiency. These machines handle large volumes of raw materials, streamline workflows, and minimize human error. Manufacturers can now meet the growing demand for textiles in a cost-effective and timely manner.

Diverse Range of Textile Products:

The versatility of textile machinery has paved the way for a diverse range of textile products. Various machines are designed to produce fabrics, yarns, threads, and non-woven materials. Manufacturers can cater to diverse market demands by adjusting machine settings, producing textiles with varying textures, colors, patterns, and finishes. This flexibility encourages creativity and innovation in the industry.

Ensuring Enhanced Quality and Consistency:

Textile machinery's precision and automation contribute to consistent quality in textile production. By eliminating human error and inconsistencies inherent in manual processes, these machines enhance the overall quality and uniformity of final products. This is particularly crucial for industries such as fashion, automotive, and medical sectors that demand consistent textiles.

Promoting Sustainable Textile Manufacturing:

In response to the increasing focus on sustainability, textile machinery plays a vital role in promoting eco-friendly practices. Advanced machinery incorporates energy-efficient technologies, reducing power consumption and minimizing environmental impact. Additionally, modern machinery facilitates the efficient use of raw materials, reducing waste in the production process. From recycling systems to sustainable dyeing and finishing techniques, textile machinery contributes to a greener future.

Technological Advancements Driving Innovation:

Textile machinery continues to evolve with technological advancements, incorporating computer-controlled systems, intelligent automation, and digital technologies. Computer-aided design (CAD) software enables intricate pattern creation, while robotics and artificial intelligence (AI) enhance productivity and automation. These advancements not only improve efficiency but also open doors for innovation, customization, and personalization in the textile industry.

Enhancing Worker Safety and Comfort:

Automation in textile machinery positively impacts worker safety and comfort by reducing the physical strain associated with labor-intensive tasks. Implementation of safety features and protocols ensures a safer working environment, contributing to a more sustainable and ethical textile industry that prioritizes worker well-being.

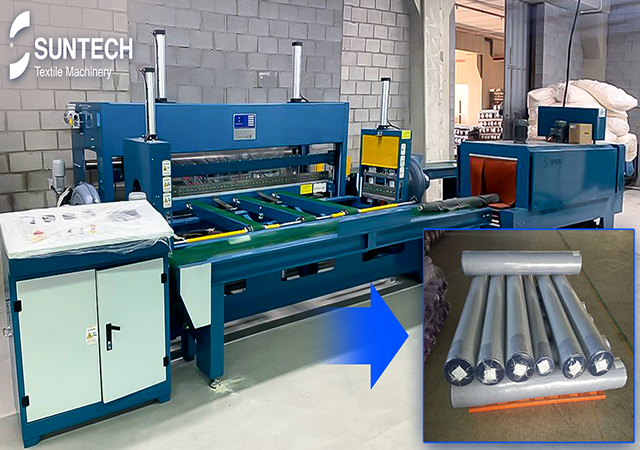

SUNTECH Textile Machinery has been deeply involved in intelligent machinery for 50 years. As a specialist in textile equipment automation, SUNTECH has developed and produced textile machinery such as automatic packaging machine, and motorized beam trolley. SUNTECH has over 10,000 customers and 50,000 machines success installed worldwide, providing professional intelligent equipment to many international textile enterprises and contributing to the world textile industry.

Textile machinery stands as a driving force behind the textile industry's efficiency, quality, and sustainability. Its role in increasing production efficiency, producing diverse textiles, ensuring quality and consistency, promoting sustainability, and integrating technological advancements empowers manufacturers to meet the demands of a rapidly evolving market. As technology continues to advance, the future of textile machinery promises even more exciting possibilities, shaping the textile industry for years to come.