Over the last few years, the share of China's fabric market has increased year by year, with the complete textile fiber processing, chemical fiber outcome, and also fabric and garments exports rating first on the planet. "Architectural modification", "technical advancement" as well as "environment-friendly growth" are still the primary styles of the advancement of the international textile industry.

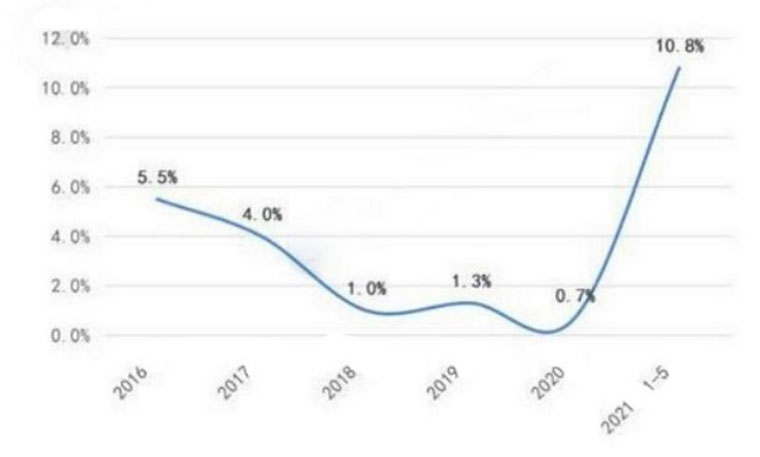

From the perspective of the included worth of the textile market, the included value of the fabric sector will certainly continue to remain in the growth array from 2016 to 2020, however the development price has declined year by year. By the initial 5 months of 2021, the cumulative included worth of the textile market will reveal a healing as well as considerable development of 10.8%.

2016-2021 year-on-year growth in the added value of the textile industry

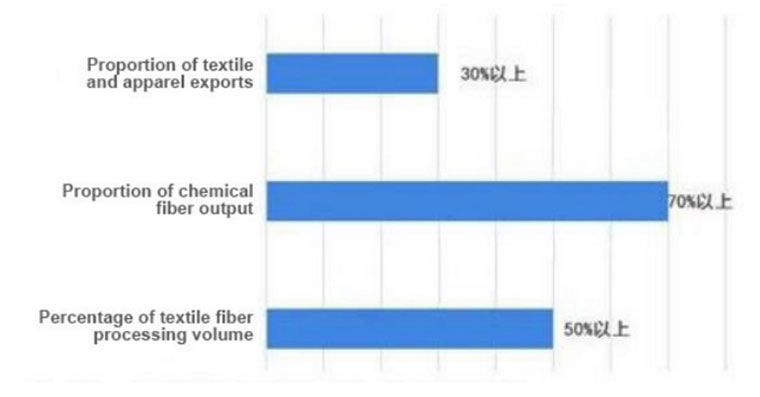

From the perspective of China's fabric sector's international market setting, in 2020, China's overall fabric fiber handling will get to 58 million heaps, making up greater than 50% of the globe's overall fiber handling; chemical fiber result will make up more than 70% of the world's textiles; Garments exports totaled up to 299 billion US dollars, making up more than one-third of the globe's proportion, rating initially worldwide.

2020 proportion of China's fabric fiber handling, fiber production and also textile exports in the global market

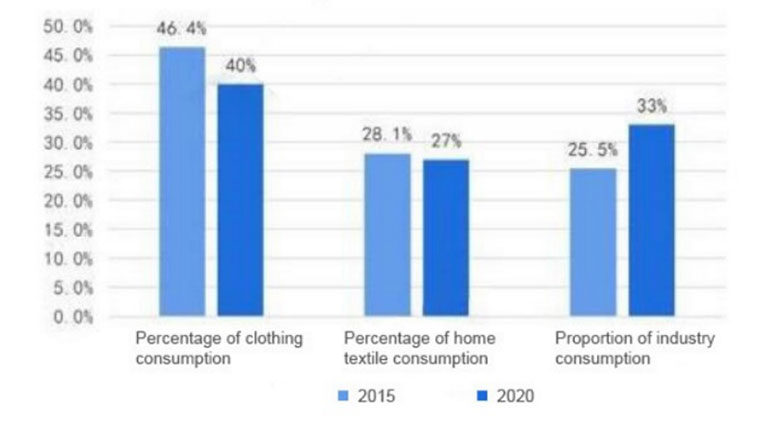

The proportion of fiber intake in the three terminal products of clothing, residence fabrics and also commercial usage will certainly be changed from 46.4:28.1:25.5 in 2015 to 40:27:33 in 2020. The proportion of commercial intake has actually boosted by 7.5 percent factors, and the incurable consumption of clothing as well as residence textiles The percentages have all declined. By the end of 2020, China's commercial fiber handling volume got to 19.1 million tons, a boost of more than 40% over 2015, properly fulfilling the requirements of diversified, multi-level, and multi-field markets. In its entirety, it shows the gradual optimization of the commercial structure of the fabric industry

2015-2020 Changes in the proportion of fiber usage in the 3 major incurable products of the textile market.

The eco-friendly environment for technical development in the entire industrial chain of the textile sector has actually continued to boost, and also great progression has actually been made in the construction of industrial advancement systems, business R&D financial investment, and equipment production. There are a number of "stuck neck" technical problems in the fields of fiber products, green production, and also fabric equipment. Was successively broken through.

The energy structure of the fabric industry remains to be enhanced, the percentage of second energy reaches 72.5%, the energy use performance is continuously improved, the extensive energy intake per 10,000 yuan of outcome worth has actually dropped by 25.5%, as well as the hazardous waste water discharge and also the discharge of major pollutants have actually stopped by greater than 10%. This shows the impressive outcomes of eco-friendly growth in the fabric industry.

It can be seen that the general textile sector is establishing rapidly and the leads are considerable. The existing market traffic jam depends on technical innovation, devices production, as well as eco-friendly environmental protection. Over the last few years, the textile sector has gradually revealed environment-friendly growth. This is also the future instructions. The world has actually currently placed research centers. In the fields of fiber products, eco-friendly manufacturing, textile machinery and various other fields, environment-friendly smart manufacturing has become a breakthrough in the industry.

Suntech has been deeply involved in the smart equipment industry for 50 years as well as is dedicated to the style as well as development of intelligent textile equipment. It has global leading modern technology. It has actually opened assembly line for smart fabric machinery, smart storage and also transportation, hygiene and intelligent looms, as well as gave professional options. It has actually effectively developed material assessment machines., Cloth assessment product packaging line, beam of light stacker, meltblown device, mask equipment, rapier impend as well as various other celebrity products. Amongst them, smart towel assessment machine, beam stacker, rapier impend, took the lead in opening originalities for textile equipment as well as overturning industry cognition, Has won many copyrighted technologies, via automation, knowledge, information design and also application, to accomplish reliable production, decrease source waste, conserve labor, decrease manufacturing prices, and also help the eco-friendly makeover of the textile sector.

Among them, the rapier impend incorporates the functions of standard looms as well as smart fabric inspection machines, and also utilizes intelligent applications to precisely develop and integrate the different weaving procedures. The finished towel can directly get in the automatic towel evaluation web link to attain the optimum manufacturing state. Make sure the quality of cloth rolls and conserve a great deal of manpower and also material sources.