The textile industry has always been a critical player in global manufacturing, but as technology continues to evolve, so do the tools and machinery used within this sector. One of the latest innovations making waves in the textile world is the integration of AGV (Automated Guided Vehicle) technology into Electric Warp Beam Trolleys. This upgrade promises to revolutionize material handling, improve efficiency, and take automation to the next level in textile production.

What is an Electric Warp Beam Trolley?

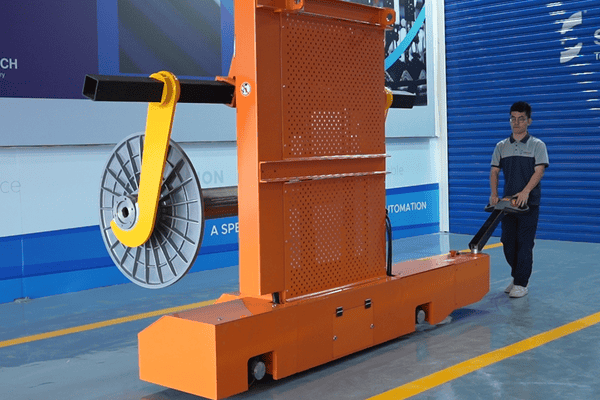

An Electric Warp Beam Trolley is a specialized vehicle designed to transport warp beams in a weaving mill or textile production environment. Warp beams are essential components in the weaving process, holding the yarns that are woven into fabric. Traditionally, these trolleys have been powered manually or through basic electric motors, but as demand for increased productivity and efficiency has risen, so too needs advanced automation.

In modern systems, Electric Warp Beam Trolleys use electric motors to transport these heavy beams, often across large, complex factory floors. While this improves basic efficiency, there is a clear opportunity to take things further with automation.

Introduction to AGV Technology

AGVs, or Automated Guided Vehicles, are mobile robots used in industrial applications for transporting goods and materials without human intervention. These vehicles are guided along predetermined paths using various technologies, such as magnetic strips, laser guidance, or vision-based systems. AGVs are widely used in various industries, including automotive manufacturing, warehouses, and more recently, textiles.

AGV systems are known for improving efficiency, safety, and accuracy in material handling. By removing the human element from the transportation of materials, AGVs reduce the risk of accidents, human error, and operational delays. In the textile industry, AGVs are now being integrated with Electric Warp Beam Trolleys to automate the process of transporting warp beams, drastically improving the production workflow.

The Need for AGV Upgrade in Electric Warp Beam Trolleys

As textile manufacturers seek to increase their operational efficiency, reduce costs, and meet rising demands, the need for more advanced systems is more pressing than ever. AGVs provide a way to achieve these goals without the risk of errors caused by human labor, while also optimizing resource allocation. By upgrading traditional Electric Warp Beam Trolleys with AGV systems, manufacturers can streamline material handling and enhance their overall production process.

The integration of AGVs allows for smoother and faster transportation, reducing the time spent moving materials between production stages and freeing up human workers to focus on more value-added tasks.

Key Benefits of AGV Upgraded Electric Warp Beam Trolleys

Increased Productivity and Reduced Labor Costs

By automating the transportation of warp beams, AGVs eliminate the need for manual labor, which not only reduces the risk of errors but also increases overall productivity. As AGVs can operate around the clock without needing breaks, textile manufacturers can significantly reduce downtime, leading to faster production cycles and higher output.

Enhanced Safety Features

The integration of AGVs into production lines helps improve safety by removing human workers from potentially hazardous tasks. AGVs can be equipped with safety sensors, which help avoid collisions and ensure smooth, controlled movement throughout the facility.

Precision and Reduced Human Error

AGVs operate on pre-programmed paths, ensuring that every task is completed with a high level of precision. This reduces the possibility of mistakes that often occur when humans are responsible for transporting heavy materials, ensuring a more reliable and efficient workflow.

Streamlined Operations and Workflow

AGVs contribute to better workflow management by seamlessly integrating with existing systems. With automated transportation, companies can create more organized, streamlined operations, reducing bottlenecks and delays in the production process.

How AGV Upgrades Improve the Functionality of Electric Warp Beam Trolleys

The combination of AGV technology and Electric Warp Beam Trolleys brings several improvements to functionality:

Automation of Repetitive Tasks: AGVs handle repetitive tasks such as moving materials from one location to another. This frees up workers to perform more critical tasks, improving overall efficiency.

Real-time Tracking and Monitoring: With AGV systems, companies can track the exact location of each warp beam, allowing for real-time monitoring and immediate intervention if needed.

Smart Routing and Path Optimization: AGVs can choose the most efficient route, adapting to changing factory layouts and avoiding congestion. This ensures that the warp beams reach their destination in the shortest time possible.

AGV’s Role in Material Handling in Textile Production

AGVs are particularly well-suited to handle heavy loads, such as warp beams, in textile production facilities. Since these beams can weigh several hundred kilograms, AGVs are designed to carry such loads with ease. By removing the need for human labor in this capacity, the risk of strain-related injuries is significantly reduced.

Furthermore, AGVs can run continuously without the need for rest breaks, which is particularly useful in high-demand environments where consistent material handling is critical to meeting production quotas.

Impact on Space Utilization and Workflow Optimization

As production facilities become more compact, space optimization becomes increasingly important. AGV systems are designed to take up less space than traditional material handling methods, which means they can operate in tighter spaces. This helps manufacturers maximize their floor space, improving overall workflow and reducing inefficiencies caused by congestion.

Future Trends in AGV and Electric Warp Beam Trolley Technologies

The future of AGV and Electric Warp Beam Trolley technologies looks bright, with ongoing research and development aimed at further enhancing the capabilities of both. Future trends may include improved energy efficiency, faster operational speeds, and more advanced AI-based decision-making for optimized operations.

Comparing Traditional and AGV-Enhanced Electric Warp Beam Trolleys

When comparing traditional Electric Warp Beam Trolleys to AGV-enhanced systems, it’s clear that AGVs offer several advantages in terms of cost, efficiency, and performance. While the initial investment might be higher, the long-term benefits far outweigh the costs, especially in terms of increased production speed and reduced labor expenses.

How Textile Manufacturers Can Benefit from AGV-Enhanced Systems

For textile manufacturers looking to stay competitive, integrating AGV-enhanced Electric Warp Beam Trolleys is a step toward future-proofing operations. These systems offer an opportunity to streamline operations, reduce costs, and improve the overall quality of production.

Practical Tips for Adopting AGV Upgrades in Your Textile Facility

Before upgrading to AGV-enhanced Electric Warp Beam Trolleys, textile manufacturers should carefully evaluate their production needs, space requirements, and available budgets. Partnering with a reputable AGV supplier and ensuring proper staff training is also crucial to the successful integration of this technology.

Conclusion

The AGV upgrade of Electric Warp Beam Trolleys is an exciting development in the textile industry. It offers manufacturers the ability to automate material handling, improve efficiency, and reduce operational costs while enhancing safety and precision. As this technology continues to evolve, it will play a key role in shaping the future of textile production.