From covering the body by leaves to keeping warm and fashionable by wearing clothes, it took a long time for human beings to develop the purposes of cloth. In this development, the invention of the series of textile machines such as fabric cutting machine, weaving loom, spinning machine is indispensable. Ancient people commonly weave cloth simply by hand loom, which was time-consuming and labor-intensive, but is the only way to produce original clothes at that time.

Until 1733, John Kay from England, saw the laborious work of weaving and began to consider the way to reduce the heavy work of the weavers. As a watchmaker, his professional habits made him deal with mechanical parts first. Thus he tried numerous times to transform the shuttle and install mechanical parts, which can free labor work. After countless experiments, he invented the flying shuttle-- a shuttle with tiny wheels that can be installed in the chute. He also equipped the loom with shuttle boxes with each shuttle box has a horizontal metal rod or spindle inside on both sides of the loom and connected them through a long wooden boards (tracks), then a belt sensor or leather knot will slide with the spindle, and each one is tied with a loose rope that are connected to the center of the loom by a cleaning stick, the weaver can control the whole loom through this cleaning stick. The weaver can slide the leather knot with one hand, driving the flying shuttle run freely on the track, so that the weft thread can pass through the warp thread quickly and can work to weave wide cloth simply by one operator.

The flying shuttle is convenient and enables factories to increase weaving efficiency highly, but it was rejected by the textile factory owners at that time because of strangeness, which made Kay eventually lose most of his property and move to France. However, the moving wheel of history promoted the acceptance and wide application of flying shuttle in a weaving factory. According to the statistics of Manchester, where the textile industry was rapidly developed at that time, the amount of yarn a weaver wove a day through a flying shuttle device was equivalent to the workload of 5-6 spinners a day. Therefore, soon the serious "veil shortage" spread to the whole of England, which has promoted and accelerated the innovation process of spinning technology.

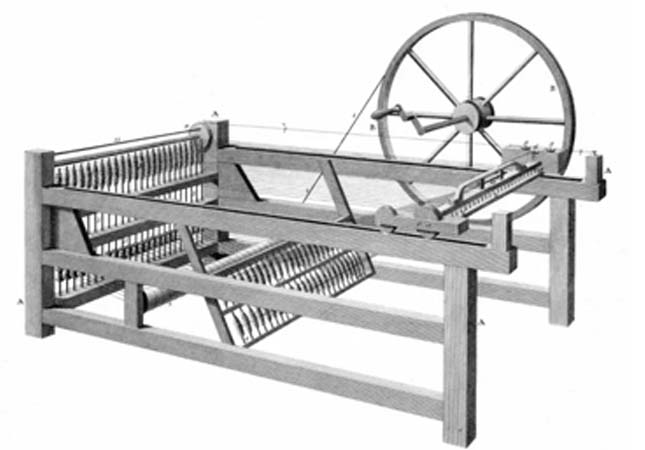

In 1765, Manchester textile worker Hargreaves knocked over his wife Jenny's spinning machine by accident, but he found that the vertical spindles and wheels of the spinning machine were still turning due to inertia. This gave him the inspiration to create a modern spinning machine by using a wheel to drive several spindles side by side. After repeated design and production, Hargreaves designed a new spinning machine that can spin 8 spindles at the same time, and named the machine after his wife. From then on, the "Jenny Spinning Machine" opened the prelude to the British Industrial Revolution. appeared.

The Jenny spinning machine was hailed by Friedrich Engels as "the first invention which radically changed the condition of the English workers" and was patented in 1770.

The self-acting mule invented by Crompton also became an essential invention in the cotton textile industry. Crompton added a sliding frame to the textile machine, which is a crucial element of a textile machine. The sliding frame is equipped with a rotating spindle, making the yarn in a straight state throughout the whole weaving process, which ensures the superior quality of spun yarn. The cotton yarns spun from it are mostly soft and fine.

Human textile civilization has a history of more than 6,000 years and weaving machines are still the main equipment in the textile industry around the world. They have improved the efficiency of producing textiles. At the same time, the times are still developing, and modern technologies have prompted the invention of modern equipment and the invention and promotion of improved equipment are also promoting the development of the textile industry.