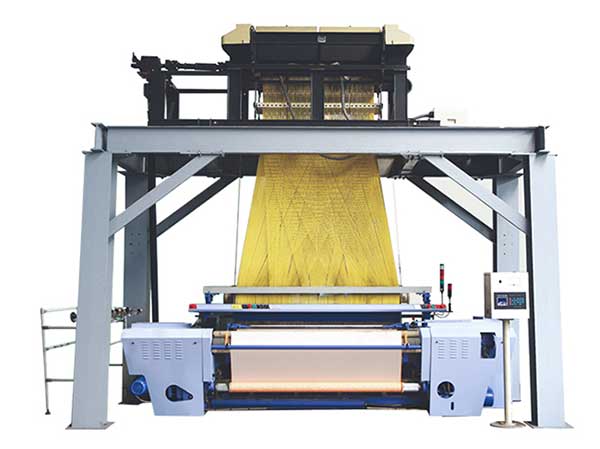

Suntech smart rapier jacquard loom continues the legend of the jacquard loom, creating an industry 4.0 era

Speaking of the Industrial Revolution, people will involuntarily think of the manufacturing industry and the textile industry. The invention of the textile machine is an important turning point in the history of the development of the textile manufacturing industry. Nowadays, when it comes to the textile industry, people's impression of textiles is still in labor-intensive textile factories. In fact, the textile industry has already moved from manual textiles to mechanical textiles and smart textiles. Smart textile machines have become important operating equipment in the textile industry.

Speaking of textile machines, we have to mention the jacquard loom. Its development history is quite legendary and full of intelligence. In the 18th century, it connected Manchester’s two most important historical industries-textile manufacturing and computers. The development of smart textiles laid the foundation.(try suntech Loom)

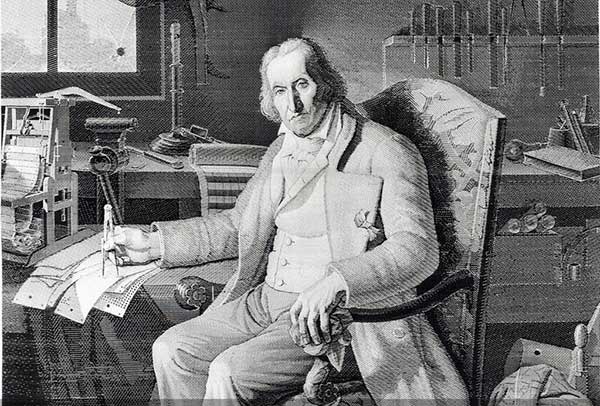

Revolutionary invention

When Joseph-Marie Jacquard, a French weaver and merchant, patented his invention in 1804, he revolutionised how patterned cloth could be woven. His Jacquard machine, which built on earlier developments by inventor Jacques de Vaucanson, made it possible for complex and detailed patterns to be manufactured by unskilled workers in a fraction of the time it took a master weaver and his assistant working manually.

The spread of Jacquard's invention caused the cost of fashionable, highly sought-after patterned cloth to plummet. It could now be mass produced, becoming affordable to a wide market of consumers, not only the wealthiest in society.

PUNCH CARDS WEAVING PATTERNS

To weave fabric on a Loom, a thread (called the weft) is passed over and under a set of threads (called the warp). It is this interlacing of threads at right angles to each other that forms cloth. The particular order in which the weft passes over and under the warp threads determines the pattern that is woven into the fabric.

Before the Jacquard system, a weaver's assistant (known as a draw boy) had to sit atop a loom and manually raise and lower its warp threads to create patterned cloth. This was a slow and laborious process.

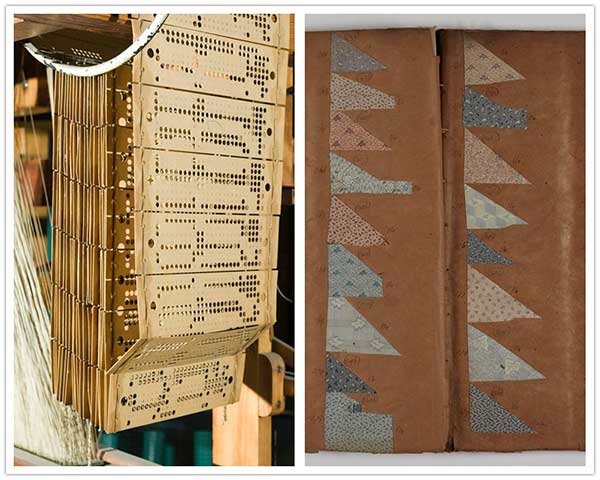

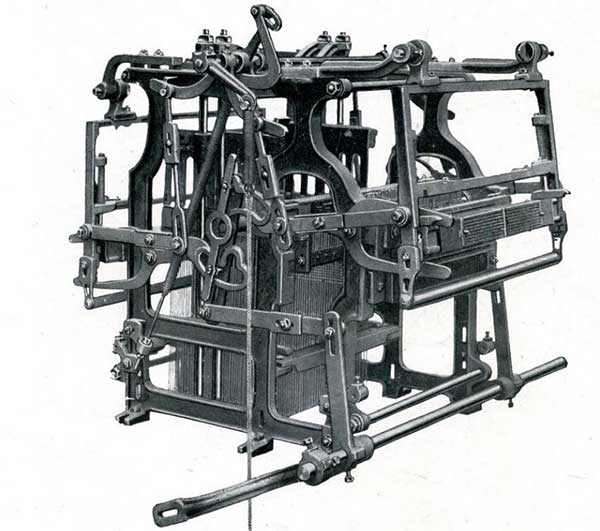

The key to the success of Jacquard's invention was its use of interchangeable cards, upon which small holes were punched, which held instructions for weaving a pattern. This innovation effectively took over the time-consuming job of the draw boy.

When fed into the Jacquard mechanism (fitted to the top of the loom), the cards controlled which warp threads should be raised to allow the weft thread to pass under them. With these punch cards, Jacquard looms could quickly reproduce any pattern a designer could think up, and replicate it again and again.

(Series of punch cards on the Jacquard hand loom in the Textiles Gallery at the Science and Industry Museum.)

STEP BY STEP: HOW A JACQUARD LOOM WORKS

Card maker using a machine to translate a pattern onto punch cardsScience Museum Group Collection, photo by permission of Garth Dawson, Accrington.

Card maker using a machine to translate a pattern onto punch cards, c. 1950.

Science Museum Group Collection, photo by permission of Garth Dawson, Accrington.

First, a designer paints their pattern onto squared paper. A card maker then translates the pattern row by row onto punch cards. For each square on the paper that has not been painted in, the card maker punches a hole in the card. For each painted square, no hole is punched.

The cards, each with their own combination of punched holes corresponding to the part of the pattern they represent, are then laced together, ready to be fed one by one through the Jacquard mechanism fitted at the top of the Loom.

When a card is pushed towards a matrix of pins in the Jacquard mechanism, the pins pass through the punched holes, and hooks are activated to raise their warp threads. Where there are no holes the pins press against the card, stopping the corresponding hooks from raising their threads.

A shuttle then travels across the loom, carrying the weft thread under the warp threads that have been raised and over those that have not. This repeating process causes the loom to produce the patterned cloth that the punch cards have instructed it to create.

THE JACQUARD LOOM IN MANCHESTER

By the 1820s, Jacquard technology had spread to Britain, where it greatly boosted Lancashire's burgeoning textiles industry, allowing Manchester and its surrounding cotton towns to produce the woven patterned textiles people craved.

From 7,000 to 8,000 Jacquard looms are now in this country... The best English designs are those in cotton goods… The Jacquard machinery is applicable to everything which is figured or flowered… every species of tissue (woven fabric) to which a loom can be applied, even to straw hats, horsehair or wire…

Banner woven on a Jacquard loom by Manchester textile manufacturers Barlow & Jones Ltd. The company made it specially for display at Manchester's Royal Jubilee Exhibition of 1887 to showcase the variety of patterned cloth they manufactured.

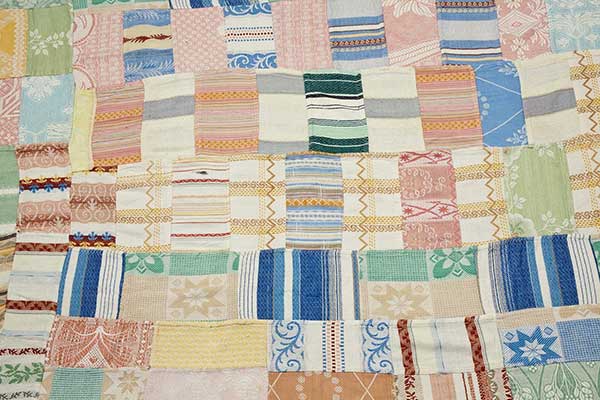

Patchwork quilt sewn from samples of Jacquard woven patterned fabric sold by Manchester cloth merchants S&J Watts.

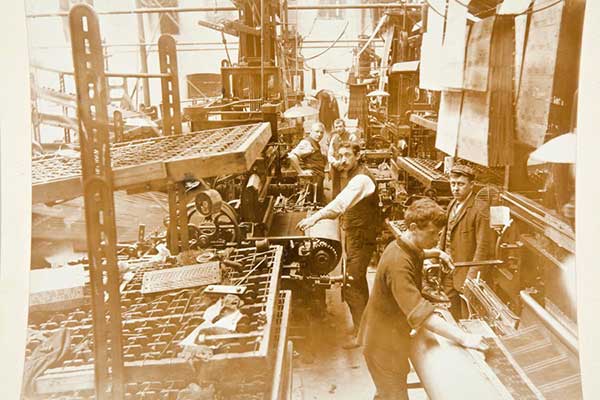

Workers at Mount Street Mill in Manchester using Jacquard looms to weave patterned seat coverings, around 1910.

Manchester engineering companies also began manufacturing Jacquard machinery to supply to the region's textile mills. Devoge and Co. was established in 1834 and continued producing Jacquard mechanisms until the 1980s.

INSPIRING EARLY COMPUTING

Jacquard's invention transformed patterned cloth production, but it also represented a revolution in human-machine interaction in its use of binary code—either punched hole or no punched hole—to instruct a machine (the loom) to carry out an automated process (weaving).

The Jacquard loom is often considered a predecessor to modern computing because its interchangeable punch cards inspired the design of early computers.

When British mathematician Charles Babbage released his plans for the Analytical Engine, widely considered the first modern computer design, fellow mathematician Ada Lovelace famously observed:The Analytical Engine weaves algebraic patterns, just as the Jacquard loom weaves flowers and leaves.

With his Analytical Engine, Babbage envisaged a machine that could receive instructions from punch cards to carry out mathematical calculations. His idea was that the punch cards would feed numbers, and instructions about what to do with those numbers, into the machine.

Ada Lovelace took Babbage's idea a step further, proposing that the numbers the engine manipulated could represent not just quantities, but any data. She saw the potential for computers to be used beyond mathematical calculation and proposed the idea of what we now know as computer programming.

Unfortunately, the Analytical Engine was never completed, and it was 100 years before Babbage's and Lovelace's predictions were realised.

However, their work, and the inspiration provided by Jacquard's revolutionary weaving machine, came to underpin the technological development of the modern computer.

With 50 years of design experience and technology precipitation, Suntech has developed and produced intelligent jacquard rapier looms to make the jacquard looms more intelligent, keeping up with the pace of Industry 4.0, and integrating various textile processes with automation and digital applications, which would require a large number of manual assembly lines. The operation link is replaced by machinery, and the intelligent cloth inspection function is perfectly integrated. It integrates intelligent textile and intelligent cloth inspection. The machine automatically inspects the finished cloth, which solves the most costly cloth inspection problem in the finishing process. The cloth inspection effect is better than manual cloth inspection, realizes the optimization of the textile process and maximizes the value, and promotes the development of Industry 4.0.

Customers who have used Suntech rapier looms are full of praise for this loom, which can be called artificial intelligence in the loom industry. According to statistics, this loom can save 20%-30% labor costs on average and increase 20%-30 %Production efficiency, in addition to automatic cloth inspection, it can also be controlled by PLC, automatic weft seeking, servo electronic warp let-off, servo electronic winding, so that every step of the textile is intelligent, and the production speed can be greatly improved. Welcome to learn more Inquiry.